Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

+86-13826586185

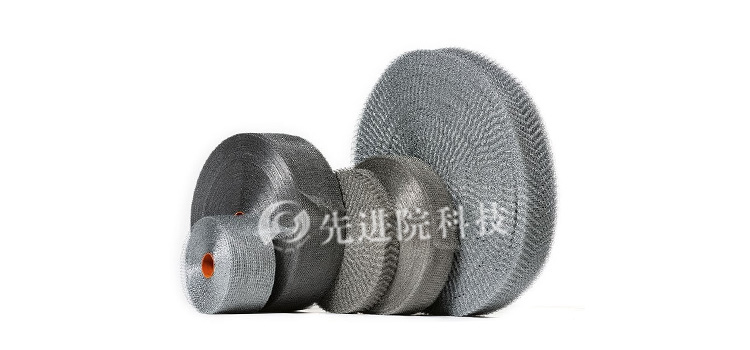

Full metal wire mesh pad is a product made by weaving compressible full metal wire, usually woven into rectangular or circular sections. The woven wire forms many spring like connecting rings, giving it good elasticity and conductivity.

The commonly used metal mesh materials for full metal mesh liners include tin plated phosphor bronze (Sn/Ph/Bz), tin plated copper-clad steel (Sn/Cu/Fe), and Monel (Ni Cu alloy). The selection of these materials is mainly based on factors such as their conductivity, corrosion resistance, and cost-effectiveness.

Full metal wire mesh pads are widely used in fields such as electronics, communications, aerospace, and healthcare, including but not limited to:

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2