Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

+86-13826586185

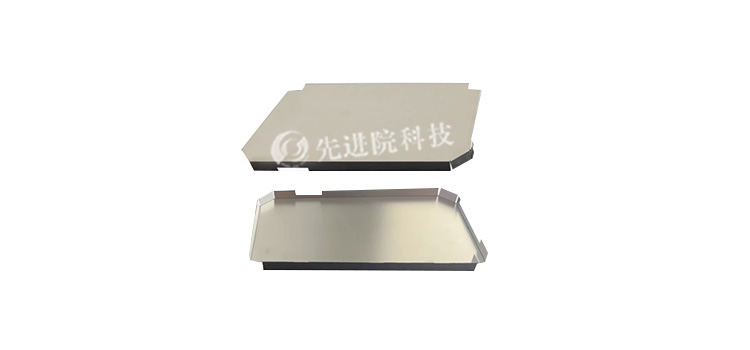

A high-precision shielding cover is a metal or non-metal casing manufactured through precision machining, used to reduce or eliminate electromagnetic interference (EMI) and electromagnetic radiation (EMR), ensuring stable operation of electronic devices in complex electromagnetic environments. Its main characteristics include high precision, high shielding effectiveness, lightweight, corrosion resistance, etc.

The selection of materials for high-precision shielding covers is crucial. Common materials include metals such as copper, aluminum, stainless steel, and phosphor bronze, as well as non-metallic materials such as plastics and ceramics. Metal materials have good shielding effect but are heavier, while non-metallic materials are relatively lighter but have slightly inferior shielding effect. Therefore, when selecting materials, it is necessary to weigh the specific application scenarios and performance requirements.

The production process of high-precision shielding covers is complex, including multiple steps such as material preparation, processing and molding, surface treatment, assembly, and testing. Among them, processing and forming is one of the key steps, and stamping, cutting, welding and other processes are often used to process materials into predetermined shapes. Surface treatment includes processes such as oil removal, rust removal, and painting to improve the corrosion resistance and appearance quality of the shielding cover. The assembly and testing process ensures that all performance indicators of the shielding cover meet the design requirements.

High precision shielding covers are widely used in the following fields:

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2