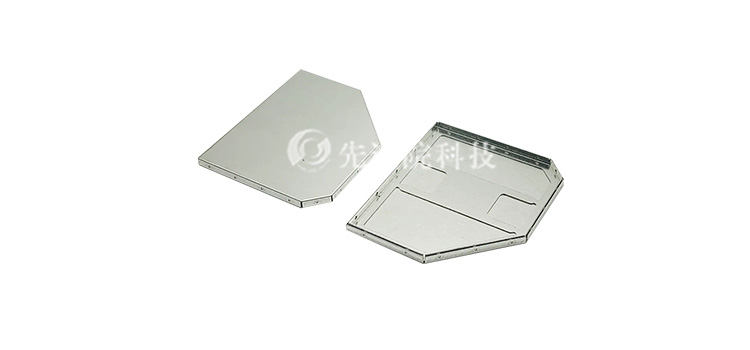

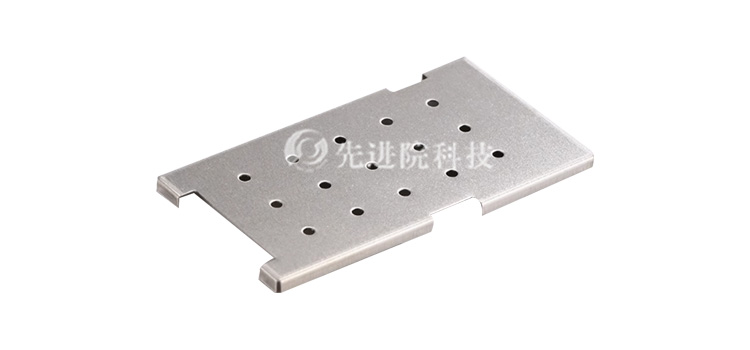

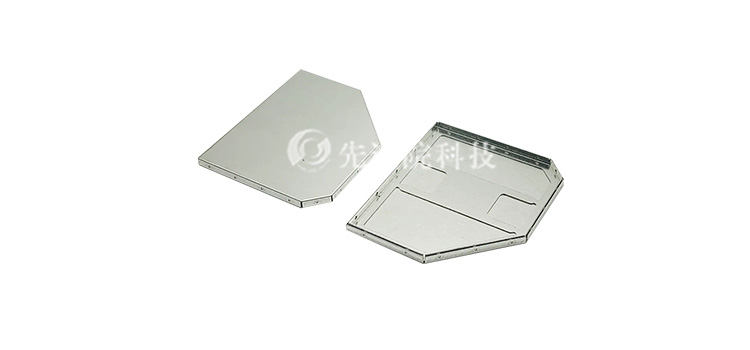

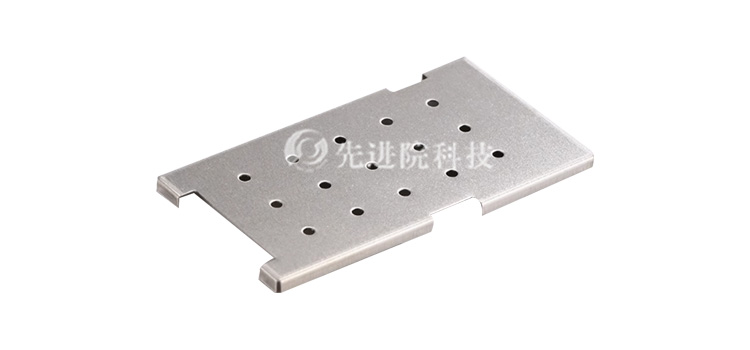

WIFI shielding cover is usually a metal shell that tightly wraps around wireless modules (such as chips, circuit boards, etc. in routers). It adopts multiple types of integrated shielding layers, with a simple structure and high cost-effectiveness. These shielding layers can effectively reduce or remove interference sources from components, circuits, cables, or the entire system.

major role

- Electromagnetic shielding:

- Preventing internal interference and leakage: WIFI shielding covers can surround the electromagnetic interference and radiation generated by wireless modules, preventing them from spreading outward and affecting other electronic devices or systems.

- Resist external interference: At the same time, the shielding cover can also block the interference of external electromagnetic fields on the wireless module, ensuring stable operation of the device in complex electromagnetic environments.

- Protecting electronic components:

- The shielding static electricity phenomenon on the circuit board provides protection for electronic components and prevents component damage caused by electrostatic discharge (ESD) and other reasons.

- The shielding cover can also protect electronic components from mechanical damage and physical impact to a certain extent.

-

Improve performance:

Production process

- Raw material selection:

- Choose high-quality metal materials such as stainless steel, aluminum alloy, copper alloy, etc.

- Stamping forming:

- Process metal materials into the desired shape through precision stamping technology. The stamping process can precisely control the size and shape, ensuring the sealing and shielding effect of the shielding cover.

- Welding/Assembly:

- For complex shaped shielding covers, it is necessary to connect their various parts through welding or assembly to form a complete shielding cover.

- Surface treatment:

- Improve the corrosion resistance and conductivity of the shielding cover through surface treatments such as nickel plating, tin plating, silver plating, etc.

- Quality inspection:

- The finished product needs to undergo strict testing, including conductivity testing, mechanical strength testing, corrosion resistance testing, etc., to ensure that the product meets the expected performance indicators.

Specific application scenarios

- Mobile phones and tablets:

- Inside mobile phones and tablets, WIFI shielding covers are used to protect Wi Fi modules, reduce electromagnetic interference, and improve signal transmission stability. This is very important for ensuring the normal operation of the equipment.

- Notebook computer:

- Inside the laptop, the WIFI shielding cover is used to protect the Wi Fi module, reduce electromagnetic interference, and improve signal transmission stability. This is crucial for improving the reliability of network connections.

- Router and Switch:

- Inside routers and switches, WIFI shielding covers are used to protect Wi Fi modules, reduce electromagnetic interference, and improve the reliability of data transmission. This is crucial for ensuring the stable operation of network devices.

- Smart home devices:

- In smart home devices such as smart speakers and smart TVs, WIFI shielding covers are used to protect Wi Fi modules, reduce electromagnetic interference, and improve signal transmission stability. This is very important for ensuring the normal operation of the equipment.

- Industrial control system:

- In various industrial control systems, WIFI shielding covers are used to protect Wi Fi modules, reduce electromagnetic interference, and improve system stability and reliability. This is very important for ensuring the normal operation of industrial equipment.