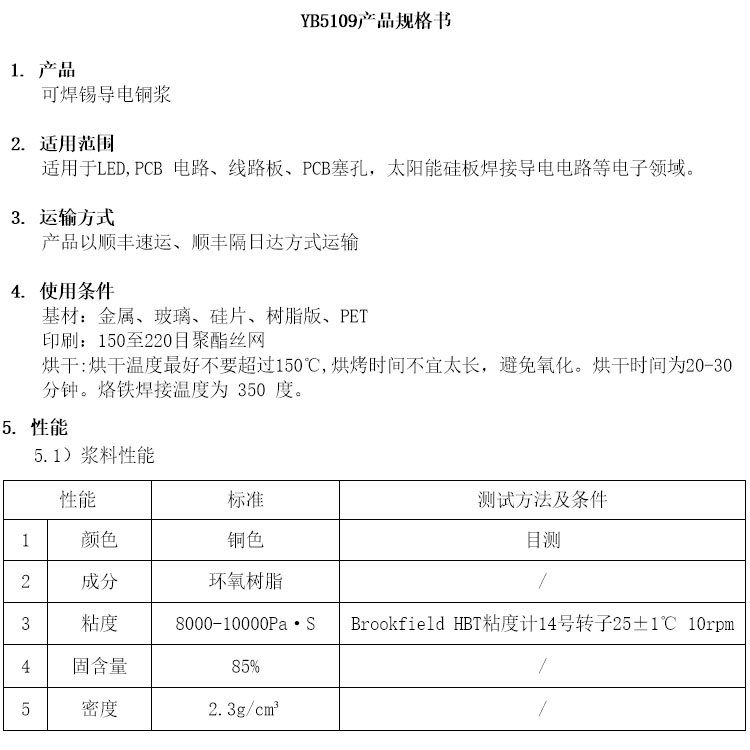

Solderable conductive copper paste is a high-performance conductive material designed specifically for the field of electronic manufacturing. It combines high-purity copper powder, special resin matrix, and soldering components, and is made through fine dispersion and mixing processes. This product not only has excellent conductivity, but also forms a good bond with solder, making it suitable for various electronic components and circuit boards that require soldering connections.

Product characteristics

- High conductivity:

- Using high-purity copper powder as the main conductive component ensures that the copper paste has extremely low electrical resistivity and provides excellent conductivity.

- Suitable for electronic components and circuit boards that require high-precision conductive connections.

- Solderability:

- Containing soldering aids, the copper paste can form good wetting and bonding with the solder during the welding process, improving the welding strength and reliability.

- No additional soldering flux is required, simplifying the soldering process and reducing production costs.

- Good processability:

- Has good fluidity and thixotropy, suitable for various processing techniques such as screen printing, spraying, and dispensing.

- It can be made into conductive structures of different shapes and sizes to meet diverse application needs.

- Stability and reliability:

- After special processing, copper paste remains stable during storage and use, and is not prone to delamination and precipitation.

- Ensure consistency and reliability of welding connections to improve the overall performance of electronic products.

- Environmental friendliness:

- Compliant with environmental standards, there is no harmful gas release during use, and it is environmentally friendly.

- Suitable for electronic component manufacturing that meets the requirements of green manufacturing and sustainable development.

application area

- Electronic manufacturing:

- Used for soldering connections of electronic components such as printed circuit boards (PCBs), flexible circuit boards (FPCs), integrated circuits (ICs), etc.

- Improve the conductivity and welding reliability of electronic products, and reduce production costs.

- In the field of optoelectronics:

- Used for conductive connection and welding of photovoltaic products such as solar panels and LED lighting.

- Improve photoelectric conversion efficiency and lighting performance, and extend product lifespan.

- Automotive Electronics:

- Used for welding connections in automotive electronic products, such as sensors, controllers, etc.

- Improve the reliability and durability of automotive electronic products to ensure driving safety.

- Other industrial applications:

- Suitable for applications in aerospace, communication equipment, medical equipment, and other fields that require high-precision conductive connections and welding.

workshop show