Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

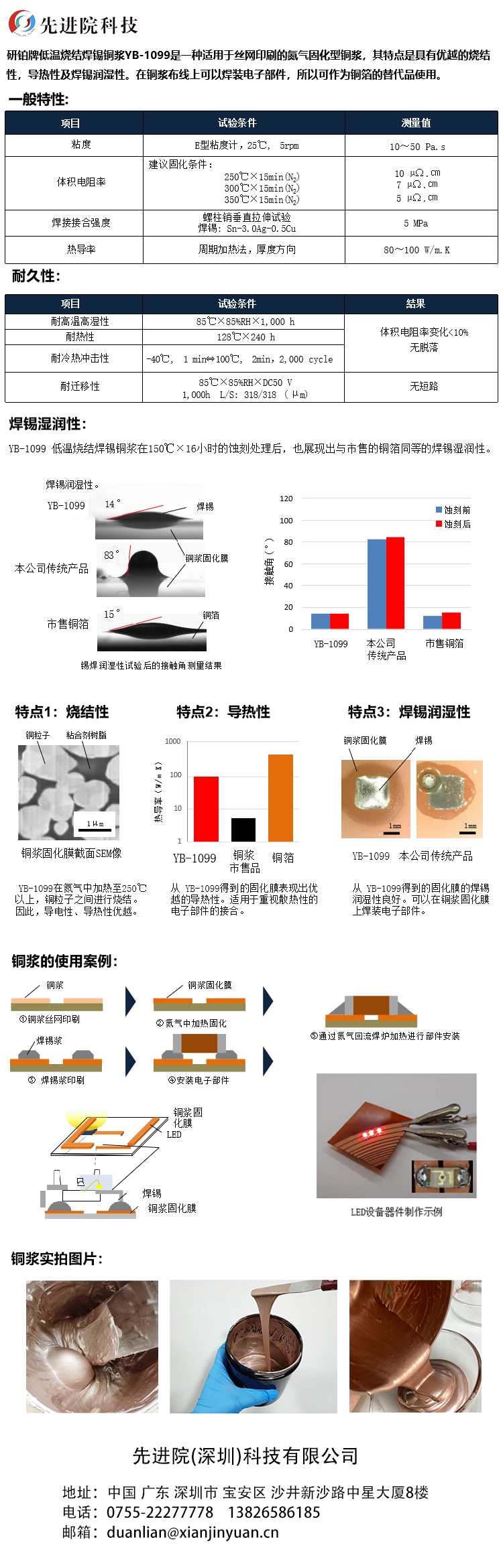

Low temperature sintered solder copper paste is an innovative conductive material that combines the conductivity of solder and the processability of copper paste, enabling sintering and solidification at lower temperatures. This material is widely used in fields such as electronic packaging, flexible circuit boards, and microelectronic devices, and is favored by the industry for its excellent conductivity, environmentally friendly properties, and simple preparation process. By precisely controlling the sintering temperature, low-temperature sintering of solder copper paste effectively reduces the thermal stress on the substrate, improving the reliability and production efficiency of the product.

+86-13826586185

Low temperature sintered solder copper paste is a special solder material commonly used to achieve metal to metal welding at lower temperatures. This type of material combines the characteristics of solder (Sn) and copper (Cu), and achieves welding through low-temperature sintering technology, thereby reducing thermal stress on the substrate, making it suitable for temperature sensitive electronic components and substrates.

Low temperature sintered solder copper paste has the following characteristics and advantages:

Low temperature sintered solder copper paste usually contains the following components:

Low temperature sintered solder copper paste can be prepared by the following steps:

Low temperature sintered solder copper paste is widely used in applications that require reliable soldering at lower temperatures, including but not limited to:

workshop show

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2