Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

+86-13826586185

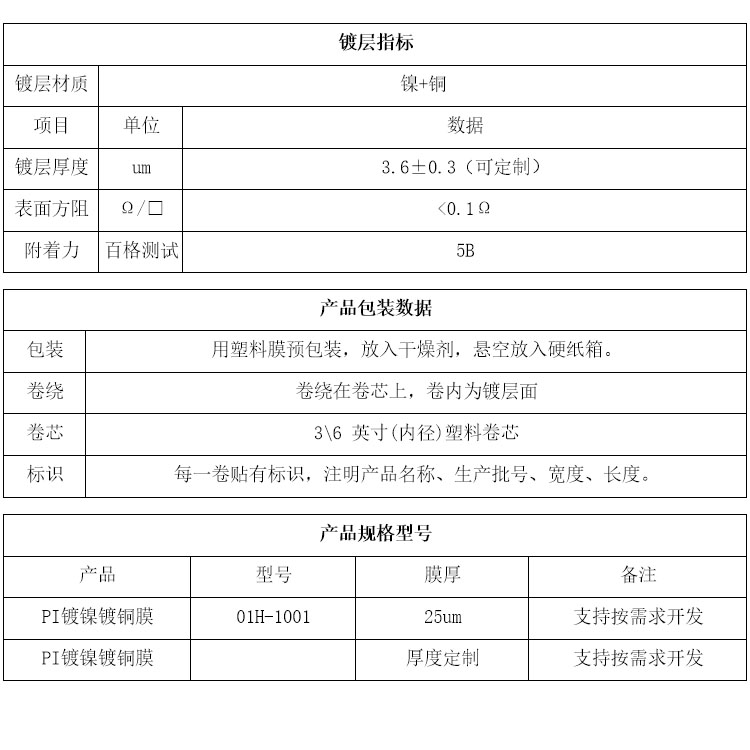

PI nickel plated copper plated film is a unique composite thin film material. The nickel copper coating on its surface is uniform and delicate, presenting a metallic luster. This film has excellent high-temperature resistance, chemical corrosion resistance, and good mechanical properties of PI film. At the same time, the nickel plating layer enhances the wear resistance and corrosion resistance of the film, while the copper plating layer endows excellent conductivity. Widely used in electronics, electrical and other fields, it can significantly improve the stability and reliability of products, making it an ideal choice for high-performance materials.

Product characteristics

High and low temperature resistance: PI film itself has excellent high and low temperature resistance, with a wide working temperature range, and can be stably used in the temperature range of -200 ° C to 300 ° C (or even wider). After nickel plating or copper plating, this characteristic is preserved, allowing the PI nickel plated copper plated film to maintain stable performance even in extreme environments.

Conductivity: Copper is an excellent conductor, and after being coated on the surface of PI film, it can significantly improve the conductivity of the material. Although nickel has lower conductivity than copper, its corrosion resistance and stability are more important in certain applications. The nickel plating layer can also serve as a protective layer for the copper layer, improving the overall corrosion resistance and wear resistance.

Electromagnetic shielding performance: Nickel and copper coatings can form a certain shielding effect in high-frequency electromagnetic fields, preventing the propagation of interference signals and interference from external electromagnetic radiation. This is particularly important for electronic devices that require electromagnetic shielding.

Chemical stability: PI film has the ability to resist corrosion and chemical erosion. After nickel or copper plating, this characteristic is further enhanced, allowing PI nickel copper plating film to remain stable in harsh chemical environments.

Mechanical and insulation properties: PI film itself has high tensile strength and wear resistance, and can withstand large mechanical stresses without easily breaking. At the same time, it also has good insulation performance, which can effectively isolate current and prevent the occurrence of circuit short circuits and leakage phenomena. After nickel or copper plating, these properties are preserved to a certain extent, but the specific properties may be affected by the thickness and process of the coating.

Production process

Pre treatment of PI film: Surface cleaning, roughening and other treatments are carried out on the PI film to improve the adhesion of the coating.

Coating deposition: Nickel and copper layers are deposited on the surface of PI film using methods such as electroplating, chemical plating, or vacuum coating. This step requires precise control of the thickness and uniformity of the coating to ensure the performance and quality of the product.

Post treatment: Clean and dry the coating to obtain the final product. The post-processing steps may also include further processing and testing of the coating to meet specific customer needs.

workshop show

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2