Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

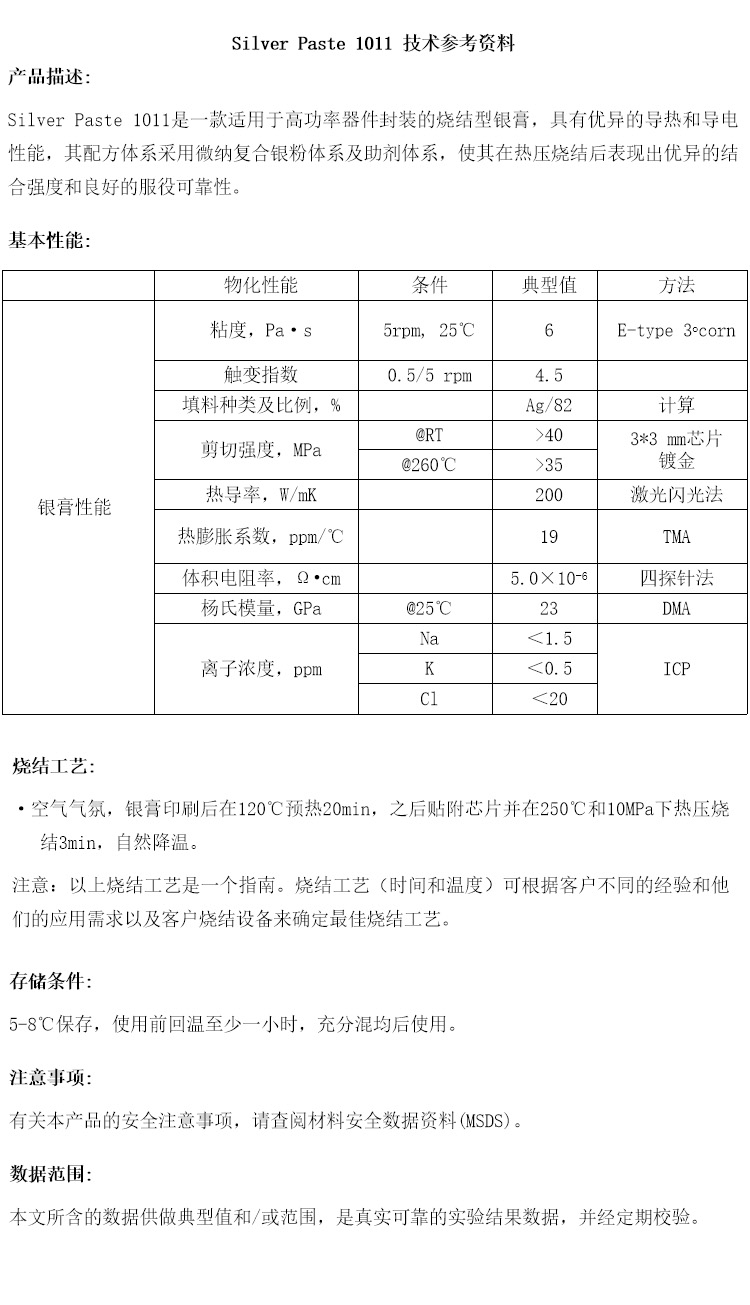

Pressure sintered silver paste forms a highly dense metal structure through advanced sintering technology, with excellent thermal conductivity, electrical conductivity, and long-term stability. This material plays an important role in the modern electronics industry, especially in high-power and high-frequency applications, providing reliable connection solutions.

+86-13826586185

Paste state: The pressure sintered silver paste maintains its paste state at room temperature, making it easy to apply or glue. This characteristic makes it easy to operate in various precision machining processes and can meet the coating requirements of complex circuits and small components.

Sintering performance: Under certain temperature and pressure, the silver powder particles in the pressure sintered silver paste will undergo sintering, forming a highly conductive and high-strength metal connection layer. This sintering process ensures the stability and reliability of the connection, making it suitable for precision fields such as high integration chip packaging.

Conductivity: Due to the presence of high-purity silver powder, pressure sintered silver paste has excellent conductivity. This enables it to provide an efficient current transmission path in electronic packaging and circuit interconnection, ensuring the stability and efficiency of the circuit.

Microelectronics packaging: Pressure sintered silver paste is widely used in the field of microelectronics packaging and is an important material for achieving fine circuit interconnection. It can provide high conductivity and high-strength connections, ensuring the stability and reliability of the circuit. In integrated circuit (IC) packaging, pressure sintered silver paste plays a crucial role.

Flexible electronics: Due to its excellent flexibility and deformability, pressure sintered silver paste has become an indispensable connecting material in flexible electronic devices such as wearable devices and smart skins. It can maintain stable electrical connections under complex deformations such as bending and folding, meeting the special requirements of flexible electronic devices.

Other fields: In addition to microelectronic packaging and flexible electronics, pressure sintered silver paste can also be used in other fields that require high conductivity and strength, such as power semiconductor packaging, high thermal conductivity circuit fabrication, etc. In addition, in three-dimensional integrated circuit (3D IC) packaging, pressure sintered silver paste significantly improves packaging density and performance through multi-layer stacking and vertical interconnection.

workshop show

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2