Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

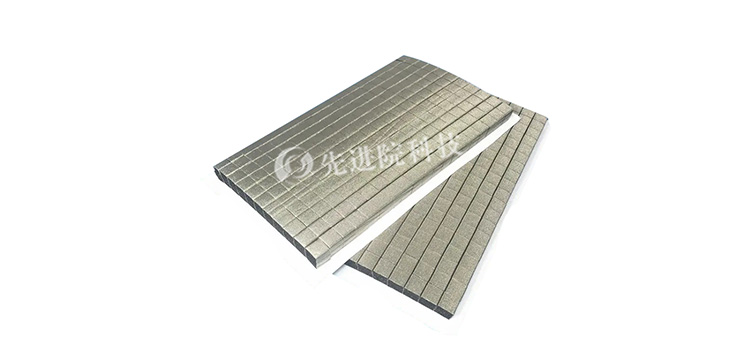

Antioxidant conductive foamAs a high-performance material, it has been widely used in fields such as electronic product manufacturing and maintenance, household appliances, communication equipment, military facilities, aerospace, and automobiles. Its unique conductivity and antioxidant properties make it a key material for solving electromagnetic interference and signal shielding problems. This article will explore the influence of the flexibility of antioxidant conductive foam on its antioxidant and conductive properties, and explain it with relevant data from Advanced Institute (Shenzhen) Technology Co., Ltd. and Yanbo brand antioxidant conductive foam.

Antioxidant conductive foam is usually made by combining conductive fiber cloth with low-pressure PU foam.Conductive fiber clothWoven from metal fibers consisting of a surface layer of copper, nickel, and other metals on the fiber surface. The fiber bottom layer is made of highly conductive copper, and the surface layer is made of nickel metal that is resistant to oxidation and corrosion. This structure not only provides excellent conductivity and shielding effect, but also has the characteristics of anti-oxidation and anti-corrosion.

For example, the research platinum brand antioxidant conductive foam has a low surface resistance value of only 0.003 Ω/sq, and its shielding effectiveness is greater than 70dB in the frequency range of 10MHz to 1GHz. This material not only has excellent conductivity, but also effectively prevents discoloration, corrosion, and fingerprint dirt through antioxidant treatment.

The flexibility of antioxidant conductive foam is an important characteristic that cannot be ignored in practical applications. Foam with good flexibility can better adapt to various complex shapes and installation environments, reduce stress concentration and mechanical damage during installation and use, thereby extending the service life of materials.

Advanced Institute (Shenzhen) Technology Co., LtdIn the development of antioxidant conductive foam, special attention is paid to the flexibility of the material. By optimizing the formula and process of foam, the product maintains high conductivity and antioxidant properties while also possessing good flexibility. Experimental data shows that the antioxidant conductive foam produced by the company maintains stable antioxidant properties after multiple bending and stretching, with minimal changes in surface resistance.

Flexibility also has a significant impact on the conductivity of antioxidant conductive foam. On the one hand, foam with good flexibility can better adhere to the conductive contact surface, increase the contact area, and thus improve the conductivity efficiency. On the other hand, foam with poor flexibility is prone to deformation and rupture when subjected to external forces, leading to the breakage or poor contact of the conductive layer, thereby affecting its conductivity.

Yanbo brand antioxidant conductive foamExcellent in flexibility. Its foam material can still maintain stable conductivity even when the compression ratio is ≥ 30%. Experimental data shows that after multiple compressions and recoveries, the surface resistance of the material changes very little, and its conductivity is stable and reliable.

In practical applications, the influence of the flexibility of antioxidant conductive foam on its antioxidant and conductive properties has been fully verified. For example, in the shielding materials of communication equipment, the use of Yanbo brand antioxidant conductive foam can effectively reduce electromagnetic interference and signal leakage, and improve the electromagnetic compatibility of the equipment. Meanwhile, due to its excellent flexibility, the material is more convenient and reliable during installation and use.

In addition, Advanced Institute (Shenzhen) Technology Co., LtdAntioxidant conductive foamIt has also been widely used in the aerospace industry. Under extreme temperature and pressure conditions, the material can still maintain stable conductivity and oxidation resistance, providing strong guarantees for the safety and reliability of aircraft.

In summary, the flexibility of antioxidant conductive foam has a significant impact on its antioxidant and conductive properties. By optimizing the formula and process of foam, the flexibility of the material can be improved, which not only extends the service life of the material, but also enhances the conductivity and shielding effect. The performance of Advanced Institute (Shenzhen) Technology Co., Ltd. and Yanbo brand antioxidant conductive foam in practical applications fully proves this point. Therefore, when developing and applying antioxidant conductive foam, the impact of its flexibility on performance should be fully considered to ensure the reliability and stability of the material in practical applications.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2