Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

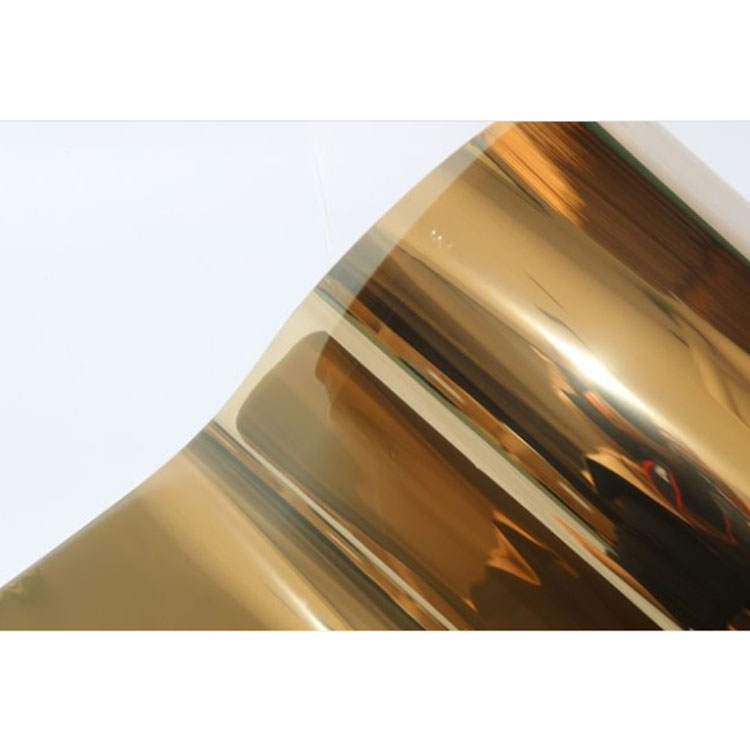

Substrate preparation: Firstly, an aluminum foil substrate needs to be prepared, which can be obtained by rolling or casting methods to obtain aluminum alloy substrates that meet the requirements.

Precision machining: After the production of aluminum foil substrate is completed, it needs to be precision machined, including aluminum foil drawing, rolling, rolling, cutting and other processing treatments, to obtain the required aperture and thickness.

Micropore preparation: After the aluminum foil is processed, it is necessary to prepare micropores using methods such as chemical etching, laser cutting, and electron beam processing to obtain a microporous structure with a pore size of 50-100um.

Surface treatment: After the preparation of micropores is completed, the surface of the aluminum foil needs to be treated to increase its surface energy and adhesion. The commonly used surface treatment methods include cleaning, activation, acid washing, etc.

Coating with active substances: After surface treatment, it is necessary to coat the aluminum foil surface with active substances to increase its adsorption and catalytic abilities towards the electrolyte. Active substances can be made of materials such as carbon, oxides, sulfides, etc., and their coating methods can include spraying, rolling, and brushing.

Testing and packaging: After coating is completed, aluminum foil products need to be tested and packaged to ensure their quality and stability. Common testing methods include visual inspection, thickness measurement, conductivity testing, and corrosion resistance testing.

2、 Performance characteristics

High conductivity: This aluminum foil product has excellent conductivity, with a resistivity of generally 2.7 × 10 ^ -8 Ω• m, which can meet the high current output requirements of lithium-ion batteries.

High specific surface area: This aluminum foil product has a special microporous structure that can increase its specific surface area, enhance its adsorption and catalytic abilities for electrolytes, and thus improve the performance of the battery.

High gas permeability: The microporous structure of this aluminum foil product can improve the ventilation performance of the battery, thereby reducing the internal pressure of the battery and minimizing the risk of leakage and explosion.

High corrosion resistance: This aluminum foil product is coated with active substances, which can effectively resist the corrosion and damage of electrolytes and oxides, maintaining its surface stability and durability.

High reliability: The manufacturing process of this aluminum foil product is precise, which can ensure the consistency and stability of its aperture and thickness, thereby improving the reliability and stability of the battery. In summary, microporous current collector aluminum foil with a pore size of 50-100um is a high-performance battery material, characterized by high conductivity, high specific surface area, high gas permeability, high corrosion resistance, and high reliability. It is an ideal choice for lithium-ion batteries.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2