Brief introduction

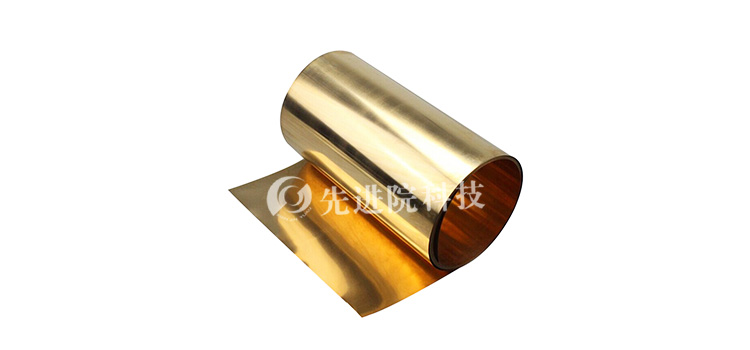

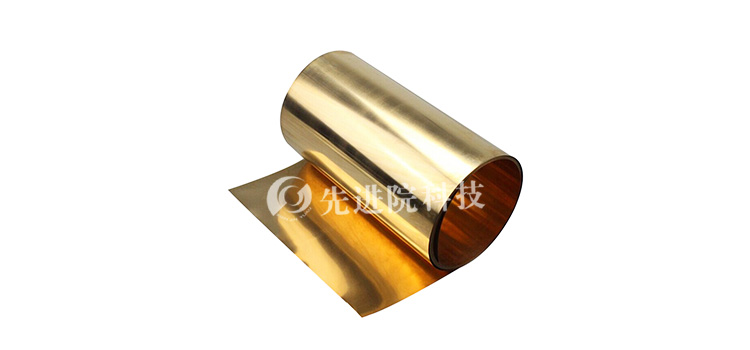

In the field of medical electronic devices, the corrosion resistance of materials is crucial. Due to the unique nature of the medical environment, equipment often comes into contact with various bodily fluids, drugs, and requires frequent disinfection processes, which places high demands on the materials used in the equipment.Copper foil gold platingAs a surface treatment technology, it has certain applications in medical electronic devices, and its corrosion resistance directly affects the service life and safety of the equipment.Advanced Institute (Shenzhen) Technology Co., LtdCopper foil gold-plated products have also received much attention in this field. This article will delve into the corrosion resistance of copper foil gold-plated products in medical electronic devices.

2、 Characteristics of Copper Foil Gold Plating

- Basic characteristics of copper foil

- Copper has good electrical and thermal conductivity, which makes it a foundation in electronic devicesconducting materialHas natural advantages. However, copper is prone to oxidation in air, and its oxidation products can affect its conductivity and mechanical properties. In medical environments, pure copper is more susceptible to corrosion.

- The protective effect of the gold layer

- Gold has extremely high chemical stability and is not prone to chemical reactions in most environments. After plating a layer of gold on the surface of copper foil, the gold layer can effectively isolate the external environment from contact with the copper foil, thereby protecting the copper foil from corrosion.

3、 Corrosion factors in medical electronic devices

- Corrosion of body fluids

- During the use of medical electronic devices, such as implantable devices (such as pacemakers) or detection devices that come into direct contact with the human body (such as blood glucose meters), it is inevitable that they will come into contact with bodily fluids. Human body fluids contain various ions, such as chloride ions, sodium ions, etc., which have a certain degree of corrosiveness. Research has shown that in a simulated body fluid environment (pH value of about 7.4, chloride ion concentration of about 103-104 ppm), untreated copper will exhibit significant corrosion within a few hours, and corrosion products such as copper green (basic copper carbonate) will form on the surface.

- Drug corrosion

- Various drugs are often used in medical environments, some of which have acidic or alkaline properties, such as certain disinfectants (such as chlorine containing disinfectants, with pH values as low as 3-4). These drugs may undergo chemical reactions with equipment materials. For ordinary copper materials, the corrosion rate will significantly increase upon contact with these drugs.

- The impact of disinfection process

- To prevent cross infection, medical electronic devices need to be disinfected regularly. Common disinfection methods include high-temperature steam disinfection, soaking in chemical disinfectants, etc. High temperature steam disinfection (up to 121-134 ° C) can accelerate the oxidation process of metal materials, while soaking in chemical disinfectants (such as hydrogen peroxide, peracetic acid, etc.) can also challenge the corrosion resistance of materials.

4、 Corrosion resistance testing and analysis of copper foil gold plating in medical electronic devices

- Salt spray test

- Salt spray test is a commonly used method to evaluate the corrosion resistance of materials. Regarding Advanced Institute (Shenzhen) Technology Co., LtdCopper foil gold platingThe product underwent salt spray testing according to standard conditions (e.g. sodium chloride solution concentration of 5%, temperature of 35 ° C). After 1000 hours of salt spray testing, it was found that the surface of the gold-plated copper foil sample only had a very slight discoloration phenomenon, while the gold-plated copper foil sample showed severe corrosion after 200 hours under the same conditions, with the corrosion area reaching more than 30% of the sample surface.

- Simulated body fluid immersion test

- In the simulated body fluid immersion test, the gold-plated copper foil product and the ordinary copper foil were soaked separately in simulated body fluid (as described earlier) for 30 days. The results showed that there were no obvious signs of corrosion on the surface of the copper foil gold-plated product, while ordinary copper foil began to show corrosion pits after soaking for 10 days, and after soaking for 30 days, the depth of the corrosion pits could reach 10-20 μ m.

- Chemical disinfectant immersion test

- Select common medical disinfectants (such as chlorine containing disinfectants) to conduct immersion tests on copper foil gold-plated products and ordinary copper foil. Soak for 1 hour and repeat 10 times. After the experiment, it was found that there were obvious corrosion marks on the surface of ordinary copper foil, and the surface roughness increased by about 50%, while the surface of copper foil gold-plated products remained basically unchanged, and the roughness only increased by about 5%.

5、 Conclusion

Copper foil gold plating has excellent corrosion resistance in medical electronic devices. Through comparative experiments with ordinary copper foil in various simulated medical environments, including salt spray test, simulated body fluid immersion test, and chemical disinfectant immersion test, the data shows that gold plating on copper foil can effectively resist the corrosion threats caused by body fluids, drugs, and disinfection processes. The performance of copper foil gold plating products from Advanced Institute (Shenzhen) Technology Co., Ltd. in these tests also proves their reliability in medical electronic equipment applications, providing strong evidence for the widespread application of copper foil gold plating in medical electronic equipment and helping to improve the service life and safety of medical electronic equipment.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.