Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Made by wrapping conductive plain or grid cloth and polyurethane sponge as raw materials.

Conductive foam is composed of highly conductive and corrosion-resistant conductive electric melting cloth, lined with low-pressure shrinkage foam.

Conductive electric melting cloth is composed of polyester fiber surface covered with copper, nickel and other metals woven and bonded with hot melt adhesive film; Hot melt adhesive film can tightly bond conductive fabric with foam The combination of copper and nickel gives the product excellent conductivity, achieving good shielding effect in the range of 30MHz to 10GHz, while also possessing anti-oxidation and anti-corrosion properties,

Widely used in various electronic products. The shielding efficiency can reach 80-110dB, and the surface resistance can reach 0.005-0.05 Ω/sq, reaching or exceeding the advanced level of similar international products. Can meet the technical requirements for electromagnetic compatibility in industries such as EMI/RFI electronics, RFID fabrics, communication, military, aerospace, medical instruments, etc

Specifications:

Width: 2mm-50mm

Length: 2mm-100m

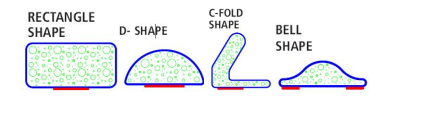

Shape: Customized mold opening according to customer requirements

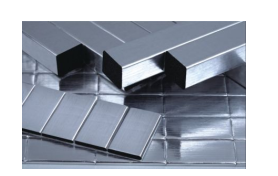

Aluminum foil conductive foam

Made by wrapping conductive aluminum foil and polyurethane sponge as raw materials.

Conductive foam is composed of highly conductive and corrosion-resistant conductive electric melting cloth, lined with low-pressure shrinkage foam.

Conductive electric melting cloth is composed of polyester fiber surface covered with copper, nickel and other metals woven and bonded with hot melt adhesive film; Hot melt adhesive film can tightly bond conductive fabric with foam The combination of copper and nickel gives the product excellent conductivity, achieving good shielding effect in the range of 30MHz to 10GHz, while also possessing anti-oxidation and anti-corrosion properties,

Widely used in various electronic products. The shielding efficiency can reach 80-110dB, and the surface resistance can reach 0.005-0.05 Ω/sq, reaching or exceeding the advanced level of similar international products. Can meet the technical requirements for electromagnetic compatibility in industries such as EMI/RFI electronics, RFID fabrics, communication, military, aerospace, medical instruments, etc

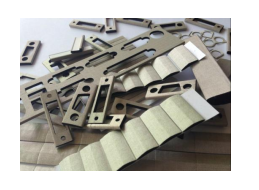

Conductive foam punching type

Made by wrapping conductive plain or grid cloth and polyurethane sponge as raw materials.

Conductive foam is composed of highly conductive and corrosion-resistant conductive electric melting cloth, lined with low-pressure shrinkage foam.

Conductive electric melting cloth is composed of polyester fiber surface covered with copper, nickel and other metals woven and bonded with hot melt adhesive film; Hot melt adhesive film can tightly bond conductive fabric with foam The combination of copper and nickel gives the product excellent conductivity, achieving good shielding effect in the range of 30MHz to 10GHz, while also possessing anti-oxidation and anti-corrosion properties,

Widely used in various electronic products. The shielding efficiency can reach 80-110dB, and the surface resistance can reach 0.005-0.05 Ω/sq, reaching or exceeding the advanced level of similar international products. Can meet the technical requirements for electromagnetic compatibility in industries such as EMI/RFI electronics, RFID fabrics, communication, military, aerospace, medical instruments, etc

Specifications:

Width: 2mm-50mm

Length: 2mm-100m

Shape: Customized mold opening according to customer requirements

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2