Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

The shrapnel provided by our company with electromagnetic wave shielding effect is made of beryllium copper alloy and can be used to seal two connections

The gap between the contact surfaces provides a high EMI shielding effect, while the beryllium copper spring provides a high shielding effect for the shielding cover

The closure required for the shielding cover is extremely low, and the beryllium copper spring has high relaxation resistance and excellent wear resistance. this

The shrapnel can be treated with various metal plating options to ensure its compatibility with any contact surface

But it will not burn or be affected by radiation. Based on these advantages, the design of computers and electrical products

Cheng Shi regards beryllium copper shrapnel as an ideal electromagnetic wave shielding material.

Beryllium copper spring has high elasticity, high conductivity, and good corrosion resistance, making it the most ideal EMI shielding material for a wide frequency range,

Widely used for shielding various communication electronic devices. The shielding spring has various structural forms and can be used in various shielding rooms/cabin doors/

Chassis/cover plate/printed circuit board plug-in board/integrated circuit shielding and other occasions. Flexible and diverse installation methods: card mounted, adhesive (3M

Pressure sensitive adhesive, riveting type, etc.

material

Beryllium copper alloy C17200 (ASTM B195)

Heat treatment: 353-435DPH/Vickers

Excellent electrical and RF conductivity

High tensile strength

High shielding effectiveness

Superb anti corrosion with excellent corrosion resistance

Long lifespan Longevity

Easy Installation

High cost-effectiveness

Multiple electroplating options Numerical plating options

Excellent performance at elevated temperature, peratures

Moisture and UV resistance

installation

Step in clip on

Adhesive backed conductive adhesive

Soldering type soldering

Locking type driving

Adhesive selection

Adhesive tape:

No adhesive or backing

Back general adhesive (non-conductive)

Back conductive adhesive

Typical shielding effectiveness

(25% compression deformation, according to MIL-STD-285 test procedure)

Magnetic field, electric field, plane wave

Standard spring 100 dB 100 dB 90 dB

Soft spring 95 dB 85 dB 75 dB

Electrochemical compatibility of coatings

:

When beryllium copper comes into contact with other metals, electrochemical corrosion occurs. It is recommended to use the following accessories to prevent electrochemical corrosion

Recommended fitting and installation surface for plating

Bright copper brass, copper, nickel copper alloy Monel、 Stainless steel, silver plated

Bright nickel brass, carbon steel, copper, nickel plating, stainless steel, tin plating

Bright tin aluminum, aluminum alloy, carbon copper, chrome plating, nickel plating, tin plating, zinc plating

Supply status

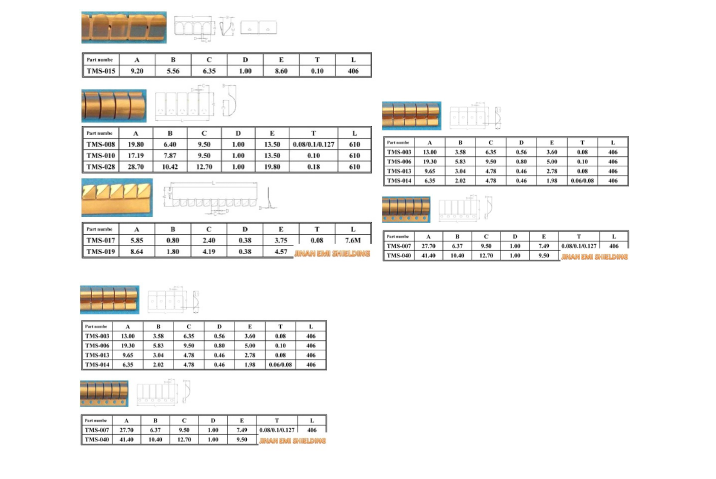

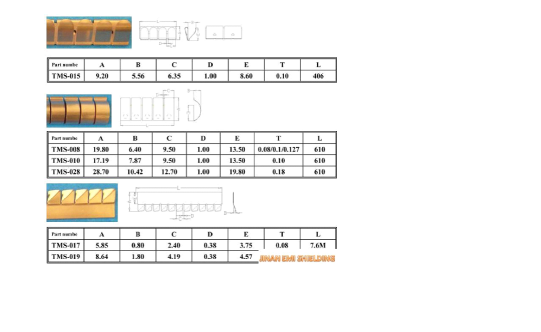

Beryllium copper spring strips are available in bright copper (natural color), tin plating, and nickel plating, with main supply lengths of 16 "(406mm) and 24"

There are two specifications of 609mm, and the required length can also be provided according to customer requirements and specific conditions.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2