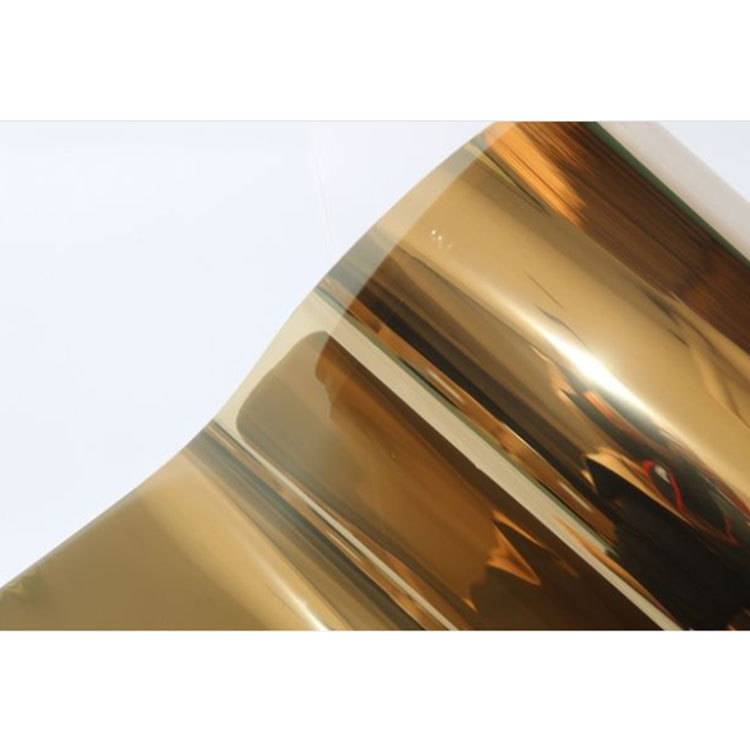

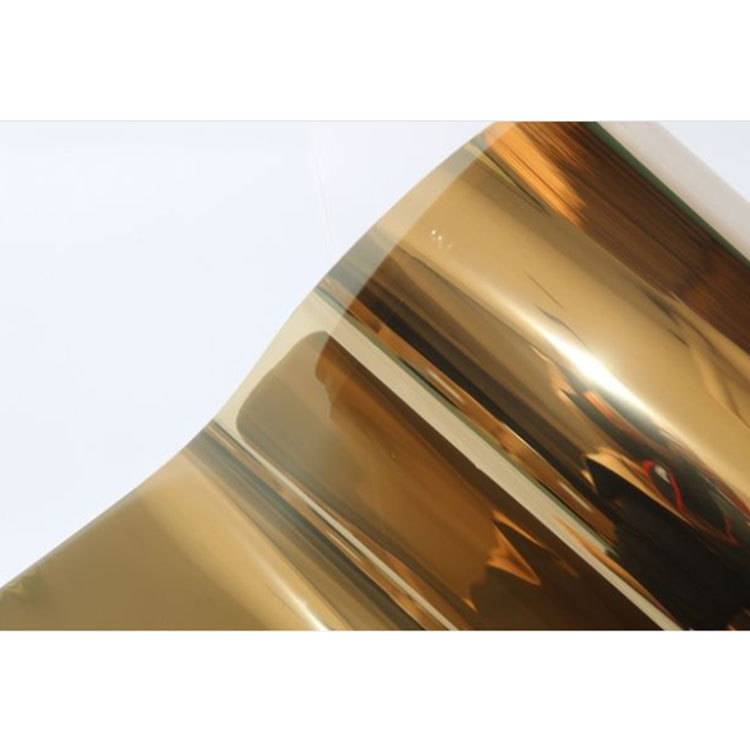

Aluminum foil refers to a thin strip of aluminum and aluminum alloy with a thickness of ≤ 0.2mm. Its hot stamping effect is similar to that of pure silver foil, so it is also known as fake silver foil. Due to the soft texture and good ductility of aluminum, it has a silver white luster. If the rolled thin sheet is mounted on adhesive paper with substances such as sodium silicate to make aluminum foil, it can also be printed. Aluminum foil is generally classified according to its thickness, condition, and purpose.

Anodized microporous aluminum foilIt is a material used to manufacture optical components, mainly applied in fields such as optical glass fibers and optical films. Its main features are very fine aperture and high strength.

Firstly, the pore size of anodized microporous aluminum foil is very fine, which can effectively reduce the noise and vibration of components, thereby improving the sound quality and quality of products. In addition, the strength of microporous aluminum foil is also very high, which can effectively resist the influence of external loads and mechanical stresses.

Secondly, anodized microporous aluminum foil also has good thermal insulation and heat retention properties, which can effectively prevent temperature fluctuations and heat loss inside the components. In addition, anodized microporous aluminum foil also has good corrosion resistance and wear resistance, which can effectively prevent the influence and corrosion of external media on components.

In addition, anodized microporous aluminum foil also has good thermal expansion coefficient and low expansion coefficient, which can effectively reduce the thermal stress and deformation of components in hot environments. In addition, anodized microporous aluminum foil also has good processability and ease of processing, and can be produced in various shapes and sizes according to needs.

In summary, anodized microporous aluminum foil is a very important optical component material, which has excellent noise reduction performance, aging resistance, and thermal stress resistance. It can improve the sound quality and quality of products, and has good characteristics such as "thermal expansion coefficient", "low expansion coefficient" and "processability", so it has been widely used in fields such as optical glass fiber and optical film.