Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

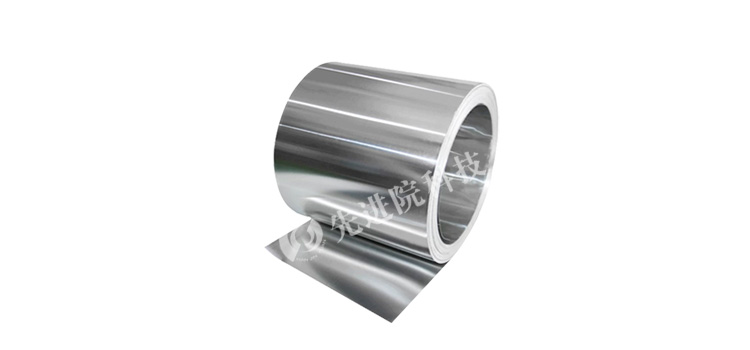

In modern electronic products, thermal stress is one of the main causes of component failure. The difference in thermal expansion coefficients between different materials can lead to stress concentration during temperature changes, which in turn can cause cracks or other forms of damage. Therefore, understanding and controlling the thermal expansion behavior of materials is crucial for improving product reliability and lifespan.PP silver plated filmAs a special type of composite material, its thermal expansion coefficient directly affects its stability and durability in practical applications.

The coefficient of thermal expansion refers to the degree to which a material undergoes length or volume changes with increasing temperature, typically expressed as a percentage change per degree Celsius. For composite materials, the different characteristics of the matrix material and the coating material will jointly affect the final coefficient of thermal expansion.

PP is a common thermoplastic with low density, good insulation properties, and excellent chemical stability. However, the thermal expansion coefficient of pure PP is relatively high, which may not be suitable for certain high-temperature application environments. By plating a layer of silver on its surface, not only can PP be endowed with better conductivity and electromagnetic shielding effect, but its overall thermal expansion coefficient can also be adjusted.

When the temperature changes, if the thermal expansion coefficients of the two materials do not match, thermal stress will be generated at their contact surfaces. This stress may lead to interface delamination, crack propagation, and other issues, seriously affecting the reliability of the device. Therefore, selecting and designing material combinations reasonably to make the thermal expansion coefficients of each part as close as possible is an effective way to reduce thermal stress.

Due to the much lower thermal expansion coefficient of silver compared to PP, PP will expand more than silver during the heating process, resulting in tensile stress between the two; During cooling, compressive stress is generated. Long term accumulated stress may damage the adhesion between the coating and the substrate, and even cause the coating to peel off.

To reduce the risk of thermal stress, the following methods can be considered:

Provided by Advanced Institute (Shenzhen) Technology Co., LtdPP silver plated filmThe solution places special emphasis on material selection and process optimization, aiming to provide products with low thermal expansion coefficient and high stability. The company has achieved a good match between PP substrate and silver coating through advanced technological means, effectively reducing stress problems caused by thermal expansion differences. In addition, the company's products also have excellent electromagnetic shielding performance and corrosion resistance, suitable for various harsh working environments.

In summary, the thermal expansion coefficient of PP silver plated film has a significant impact on its application in electronic devices. Understanding and optimizing this parameter can help engineers better manage thermal stress, improve product reliability and service life. By selecting appropriate materials and technical solutions, such as the high-quality PP silver plated film provided by Advanced Institute (Shenzhen) Technology Co., Ltd., the overall performance of composite materials can be significantly improved to meet increasingly stringent application requirements.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2