Ultra thin tinned copper foilIt is a commonly used copper foil with excellent conductivity, corrosion resistance, and ductility, and is inexpensive. The preparation methods of ultra-thin tin plated copper foil mainly include chemical copper plating method and electrical discharge deposition method.

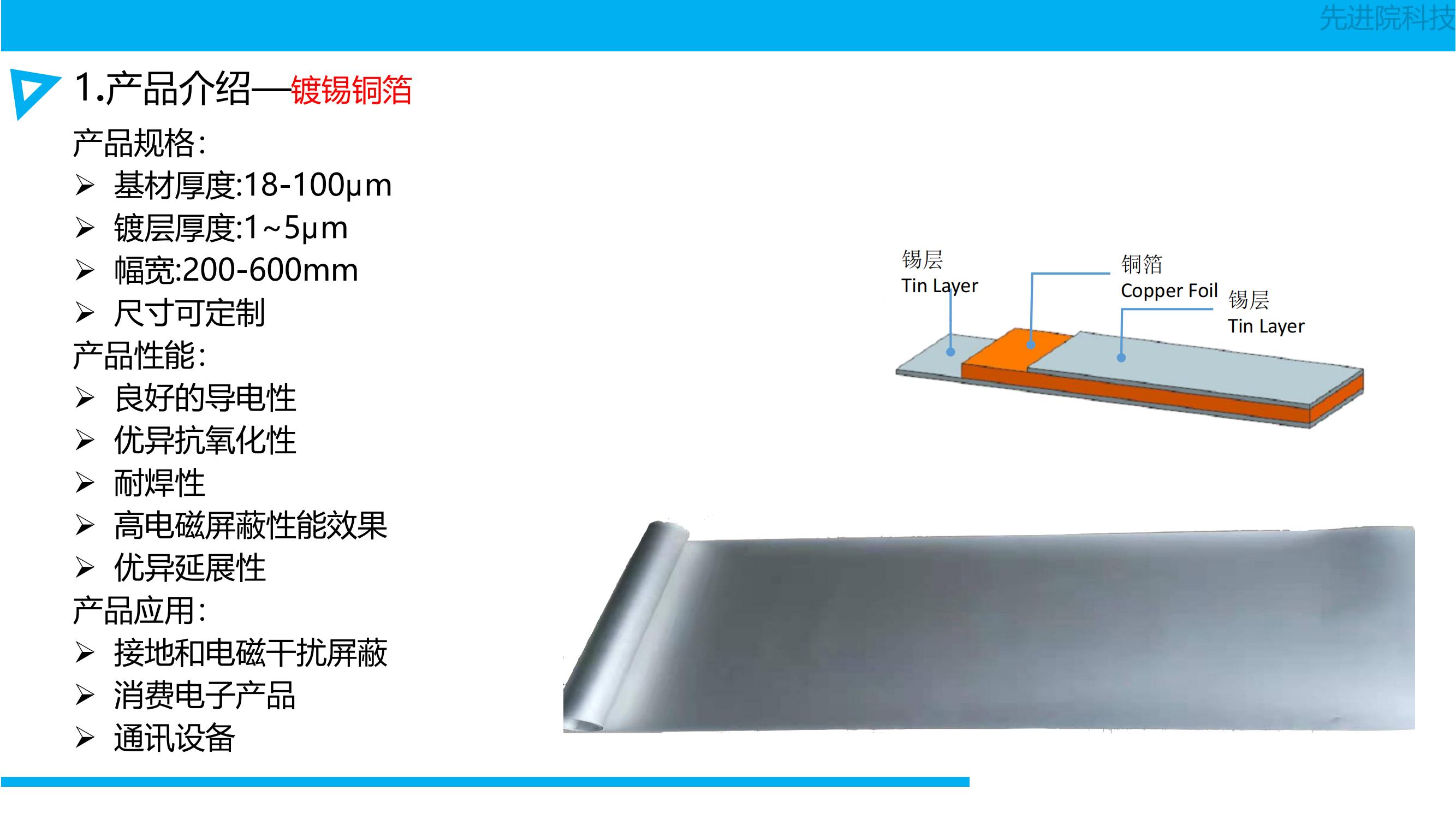

Material composition: Ultra thin tin plated copper foil is mainly composed of two metal elements, copper and tin. Among them, the copper content accounts for about 60% of the total mass of ultra-thin tin plated copper foil. In addition, other metals such as tin, aluminum, and zinc can be added to improve the performance of the material.

Process flow: The preparation of ultra-thin tin plated copper foil requires steps such as grinding, pre plating, electroplating, and post plating. Firstly, it is necessary to mix copper powder and tin, and then deposit an ultra-thin tin plated copper foil on the friction surface. During the deposition process, it is necessary to control the current density and voltage of electroplating to ensure the quality of ultra-thin tin plated copper foil. Next, it is necessary to pre coat the ultra-thin tin plated copper foil to form a good surface protective film. Post plating is the process of electroplating ultra-thin tin plated copper foil with a thickness of 1-5 μ m to form a metal thin film.

Performance characteristics: Ultra thin tin plated copper foil has excellent conductivity and corrosion resistance. It has excellent conductivity and can meet the needs of modern electronic products and semiconductor devices. At the same time, it has good corrosion resistance and can resist the influence of environmental factors such as atmosphere, acid, and alkali. In addition, it also has the advantages of low cost and easy production, and has been widely used in many fields.

● Usage:

Ultra thin tinned copper foilSuitable for the manufacturing of electronic products and semiconductor devices. In electronic products, ultra-thin tin plated copper foil is often used as one of the conductive substrates for making capacitors, circuit boards, etc. In semiconductor devices, ultra-thin tin plated copper foil can be used to make conductive components and insulating materials.

In summary, ultra-thin tin plated copper foil is a high-performance and highly reliable material suitable for many applications in various fields.