Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

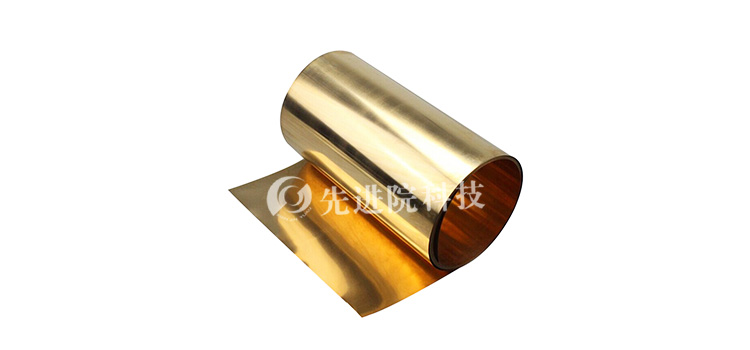

Copper foil gold plating, as an important technology in the electronics industry, is widely used in fields such as integrated circuits, chip packaging, and circuit boards. The gold plating layer not only improves the conductivity of copper foil, but also endows it with excellent corrosion resistance and oxidation resistance. However, the bonding strength between the gold plating layer and the copper foil substrate is one of the key factors affecting its performance and application. This article will explore methods to improve the bonding strength of copper foil gold plating layer from the aspects of substrate pretreatment, plating solution formula optimization, electroplating process control, and post-treatment, and combine with the advanced research institute (Shenzhen) Technology Co., LtdCopper foil gold platingElaborate on the research achievements in the field of technology.

The impurities such as grease, dirt, and oxides that may exist on the surface of copper foil can seriously affect the adhesion of the coating. Therefore, cleaning treatment before gold plating is crucial. Advanced Institute (Shenzhen) Technology Co., Ltd. adopts efficient chemical cleaning and ultrasonic cleaning technology, combined with mechanical polishing, to ensure that the copper foil surface is clean and free of impurities. This comprehensive cleaning method can effectively remove grease and oxides on the surface of copper foil, laying a good foundation for the subsequent gold plating process.

The cleaned copper foil needs to undergo activation treatment to increase surface activity and improve the adhesion of the coating. Research has shown that through electrochemical activation methods, a rough and fresh metal surface can be formed on the surface of copper foil, which is beneficial for the adhesion of the coating. Advanced Institute of TechnologyCopper foil gold plating processIn the process, a specific activation solution is used to activate the copper foil, forming a blurred interface with canine teeth interlocking, significantly improving the adhesion between the coating and the substrate.

The main components of gold plating solution include gold salts, conductive salts, buffering agents, and brighteners.Advanced Institute (Shenzhen) Technology Co., LtdThrough long-term research and practice, a high-performance gold plating solution formula has been developed. This formula has the advantages of stable process, long tank life, fast deposition speed, and uniform distribution of coating. Specifically, the additive components in the plating solution have been carefully optimized to significantly improve the adhesion between the coating and the substrate.

The plating solution will gradually consume and contaminate during use, so the maintenance of the plating solution is crucial. Advanced Institute (Shenzhen) Technology Co., Ltd. adopts measures such as regular replacement of plating solution, use of efficient filtration system to remove impurities, and strengthening operation training to ensure the stability and cleanliness of plating solution. Through these measures, the company can continue to provide high-quality gold plating services to meet the strict requirements of customers.

Current density is one of the key factors affecting the quality of coatings.Advanced Institute of Technology Copper Foil Gold PlatingIn the process, advanced power control systems are used to precisely control the current density during the electroplating process. By optimizing the current density parameters, the coating thickness is ensured to be uniform, without defects such as bubbles and pinholes, thereby improving the adhesion of the coating.

The temperature and time during the electroplating process also have a significant impact on the quality of the coating. Advanced Institute (Shenzhen) Technology Co., Ltd. sets appropriate temperature and time parameters based on the characteristics of the plating solution and process requirements. By precisely controlling these parameters, the coating is ensured to have good uniformity and density, thereby improving the adhesion and overall performance of the coating.

To improve the corrosion resistance of the coating, passivation treatment can be performed after gold plating. Advanced Institute (Shenzhen) Technology Co., Ltd. uses environmentally friendly passivation solution to treat the gold plating layer, forming a dense protective film. This protective film can not only improve the corrosion resistance of the coating, but also further enhance the adhesion between the coating and the substrate.

Other post-processing steps such as polishing and grinding can be performed as needed. These steps can further improve the smoothness and adhesion of the coating, and enhanceCopper foil gold-plated productsThe overall quality.

Improving the adhesion of copper foil gold plating layer is a comprehensive process that requires starting from multiple aspects such as substrate pretreatment, optimization of plating solution formula, electroplating process control, and post-treatment. Advanced Institute (Shenzhen) Technology Co., Ltd. has accumulated rich experience in copper foil gold plating technology through long-term research and practice. The company adopts advanced cleaning technology, activation treatment process, plating solution formula, and electroplating process control methods to ensure that the copper foil gold plating layer has excellent adhesion and overall performance. In the future, with the continuous advancement of materials science and technology, copper foil gold plating technology will play a more important role in the electronics industry.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2