Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

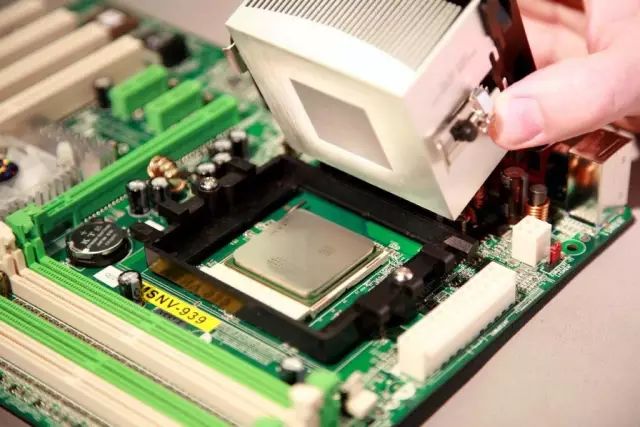

Precautions for Pre treatment of Nickel Plated Copper Wire: After each degreasing, the copper wire must be rinsed clean with hot and cold water. If not cleaned thoroughly, soap and other substances can easily be carried into the pickling solution, forming fatty acids and hindering the pickling process. After pickling, copper wire should be rinsed with at least two cold water rinses. Before entering the plating tank, it should also be washed with distilled water (or deionized water) to prevent impurities from entering the plating tank.

The reason for annealing nickel plated copper wire: After pulling, the plasticity of nickel plated copper wire decreases, and the tensile strength and hardness significantly increase. Due to the performance requirements of the product, nickel plated copper wire must be annealed.

Introduction to Nickel Plated Copper Wire: Annealing Methods for Nickel Plated Copper Wire: Using Can type and Bell type Furnaces. Although the recrystallization temperature of nickel is 530-660 ℃, the recrystallization temperature of copper is 230 ℃, so the annealing temperature of nickel plated copper wire should not be too high. The annealing temperature in the tank furnace is 2500 ℃, and the annealing temperature in the bell jar furnace is 330-350 ℃. The arrangement of nickel plated copper wires in the annealing furnace must ensure that each plate is uniformly heated and not rapidly heated to prevent bonding and loss of luster.

Tinned CopperDue to different base materials, the price varies. The price of copper base material is high at 66000 yuan per ton, while the price of brass base material is low at around 40000 yuan per ton, similar to the price of white copper. Understanding that the prices of these three materials are one of the differences in price, and using the polishing method to distinguish between them, grinding tin plated copper and nickel plated copper on cement floor simultaneously will cause color loss, while white copper will not cause color loss. Secondly, burning these materials with a lighter can distinguish them. Tin plated copper quickly changes color, nickel plated copper does not easily change color, and white copper does not change color.

In high-temperature environments, especially in aerobic high-temperature environments, tin will rapidly corrode. As the acidity increases, its corrosion strength will also increase. For example, in high-temperature acidic environments, the tin plating layer may quickly turn into slag.

Nickel has high mechanical strength and plasticity, and has strong stability in the atmosphere, even in various acidic and alkaline solutions, the vast majority of inorganic salts, and organic acids. At room temperature, nickel can form a NiO protective film, and oxidation only occurs when the working environment exceeds 500 degrees. Therefore, nickel plated copper is the preferred material for wires in high-temperature working environments.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2