Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

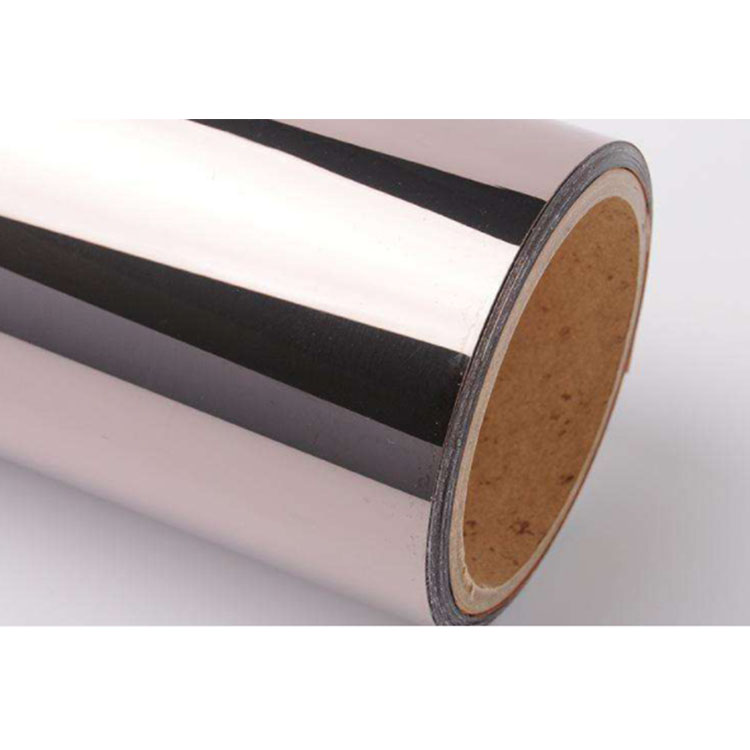

Tin plated aluminum foilIt is a processing method of coating tin on the surface of aluminum foil to enhance its rust prevention, corrosion resistance, and wear resistance. Tin plated aluminum foil has excellent sealing and preservation properties, and is widely used in packaging for industries such as food, medicine, and cosmetics. It also has functions such as UV protection, anti-static, and flame retardant. In industrial production, tin plated aluminum foil is also used in fields such as capacitors and cable packaging.

Tin plating refers to the processing method of coating tin onto the surface of a substrate (here referring to aluminum foil). The use of tin can enhance the corrosion resistance of materials, improve sealing and insulation properties. The production process of tin plated aluminum foil generally consists of several main steps, including aluminum foil surface pretreatment, tin layer covering and drying, forming, cutting, and other processes.

Firstly, perform surface treatment on the aluminum foil. Surface treatment of aluminum foil is an important step in ensuring adhesion. In this step, the surface of the aluminum foil needs to be cleaned chemically to remove any impurities on its surface, ensuring that the "tin layer" can adhere evenly to the surface of the aluminum foil. This cleaning method may involve multiple cleaning processes (such as acid-base washing). Afterwards, the surface of the aluminum foil will be washed with water to remove any residual chemicals and reduce the surface resistivity.

Next, tin layer covering and drying will be carried out. This step involves placing a tin film on the surface of the already processed aluminum foil and using some heating or other heat treatment methods to allow the tin to adhere to the surface of the aluminum foil to form a tin layer. The average thickness of the tin layer is generally about 0.01 to 0.02 millimeters. In addition, different thicknesses can be applied to the tin layer according to different applications to achieve different wear or corrosion resistance properties.

After surface treatment with aluminum foil and tin layer covering, the next step is molding. During the molding process, the aluminum foil will be rolled into the desired shape, such as cylindrical, rectangular, etc., and then cut. Some advanced forming equipment can use liquid rolling technology to apply a buffer medium that maintains lubricant on the aluminum foil before it is compressed. This helps prevent surface defects from occurring during the manufacturing process.

The final step is the cutting stage. In this stage, the aluminum foil will be cut into the required size and shape to meet the packaging needs of different products. During the cutting process, attention should be paid to the quality of the aluminum foil edges, and the cutting should be neat to avoid sharp edges and burrs, which may affect the aesthetics and safety of the packaging.

Advantages and disadvantages of tin plated aluminum foil:

(1) Advantages:

Tin plated aluminum foil can effectively extend the shelf life of food and other products.

Due to the presence of tin layer, tin plated aluminum foil has higher adaptability to environmental changes such as heat, cold, and light, and is not easily corroded or oxidized, making the taste, color, and quality of food less likely to change.

Due to the addition of tin layer, tin plated aluminum foil can enhance the sealing and sealing properties, thereby reducing the contamination of food, medicine and other products due to external factors, and maintaining the freshness and hygiene of the products.

(2) Disadvantages:

Tin plated aluminum foil has a higher cost.

Tin plated aluminum foil is not suitable for packaging under high temperature conditions.

Due to the presence of tin, there are also some doubts about environmental protection and other issues.

Application areas:

Tin plated aluminum foil is widely used in the packaging industry, such as food, medicine, cosmetics and other industries. Because the use of food and other aspects must protect the green and nutritional content of food, the use of tin plated aluminum foil perfectly meets these needs. For example, milk powder packaging, bread packaging, various candy packaging, and other types of food packaging.

In addition, the performance of tin plated aluminum foil also meets the needs of industrial mass production, and has been widely used in some fields such as electrical manufacturing, vacuum electronic surfaces, capacitors, etc. Overall, tin plated aluminum foil has a wide range of applications and significant advantages. For many industries, it is an essential material.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2