Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

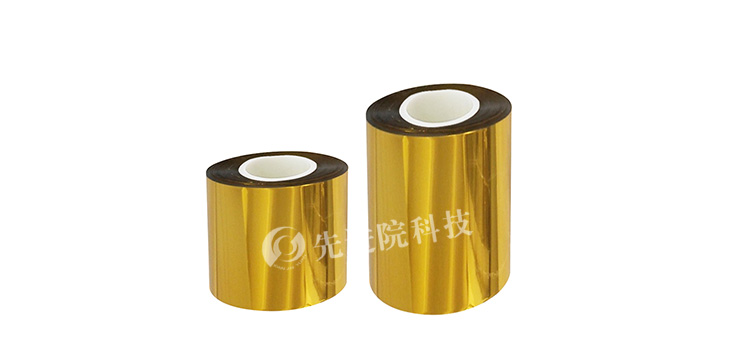

PET gold-plated film, as a composite material coated with a thin layer of gold on the surface of polyethylene terephthalate (PET) film, has been widely used in various fields such as electronic devices, flexible circuit boards, and flexible displays due to its excellent conductivity, corrosion resistance, and decorative effect. However, in certain specific application scenarios, such as screen protection,PET gold-plated filmExcellent anti glare performance is also required to ensure clear and interference free image quality. This article will explore how to improve the anti glare performance of PET gold plating film by optimizing its coating structure, and introduce the technological progress of Advanced Institute (Shenzhen) Technology Co., Ltd. in this field.

Optimize PET substrate material

Enhancing substrate toughness: By improving the formulation or production process of PET materials, such as adding appropriate toughening agents or anti bending agents, the toughness and anti bending performance of PET itself can be improved, thereby reducing the risk of coating rupture during bending or folding processes.

Improving substrate surface energy: PET material has low surface energy and a certain degree of chemical inertness, resulting in relatively weak adhesion between it and the coating. Therefore, surface modification techniques such as plasma treatment, chemical etching, etc. can be used to improve the activity of PET surface and enhance its adhesion to the coating.

Choose the appropriate coating material

Choose a coating material with a thermal expansion coefficient similar to that of the PET substrate to reduce thermal stress caused by temperature changes, thereby reducing the risk of coating cracking.

The coating material should have good corrosion resistance and conductivity, while also considering its reflection and scattering characteristics of light to reduce glare.

Control the thickness of the coating

The thickness of the coating has an impactPET gold-plated filmThe key factors of conductivity, corrosion resistance, and mechanical properties. Experimental data shows that as the thickness of the gold plating layer increases, the conductivity of PET gold plating film is significantly improved, and its corrosion resistance is also enhanced. However, excessive coating may alter the shape and size of PET film, affecting assembly accuracy with other components and increasing costs.

Therefore, the appropriate coating thickness should be selected according to specific needs to balance multiple factors such as conductivity, corrosion resistance, cost, and assembly accuracy.

Optimize sedimentary parameters

During the sputtering coating process, parameters such as deposition rate, deposition temperature, power, and working pressure should be adjusted reasonably to reduce film stress and improve coating quality.

By stepwise deposition or multi-layer structural design, stress can be further dispersed and reduced, improving the stability and anti glare performance of the coating.

Apply anti glare coating

Coating a layer of anti glare coating on the surface of PET gold-plated film can effectively reduce the reflection and scattering of light sources on the screen, and reduce glare phenomenon.

Anti glare coatings should be composed of monomers with anti glare properties, such as acrylic esters, hydroxybenzoate esters, etc., and coated and cured under appropriate process conditions.

Advanced Institute (Shenzhen) Technology Co., Ltd. has rich technological accumulation and innovative achievements in the field of PET gold plating film. The company adopts advanced electroplating technology and precise coating thickness control technology, which can produce products with excellent conductivity, corrosion resistance, and decorative effectsPET gold-plated film products.

In addition, the company is constantly exploring and optimizing the coating structure of PET gold plating film to improve its anti glare performance. By introducing surface modification technology, selecting suitable coating materials, and optimizing deposition parameters, the company has successfully developed a series of PET gold plating film products with excellent anti glare performance, which are widely used in fields such as display screen protection, electronic devices, and flexible circuit boards.

Optimizing the coating structure of PET gold plating film is an effective way to improve its anti glare performance. By enhancing substrate toughness, improving substrate surface energy, selecting appropriate coating materials, controlling coating thickness, optimizing deposition parameters, and applying anti glare coatings, the anti glare performance of PET gold plating film can be significantly improved to meet the needs of more high-end application scenarios. The technological progress of Advanced Institute (Shenzhen) Technology Co., Ltd. in this field provides strong support for the further development and application of PET gold plating film.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2