ITO conductive film is an inorganic transparent conductive thin film composed of indium oxide and tin oxide. Its conductivity and high transparency make ITO conductive films widely used in fields such as optoelectronic displays, touch screens, solar cells, LED lighting, etc. Crystalline ITO conductive film is a new type of ITO conductive film, which has better mechanical stability and conductivity compared to amorphous ITO conductive film. This article will provide a detailed introduction to crystalline ITO conductive films.

1. Principle of Crystalline ITO Conductive Film

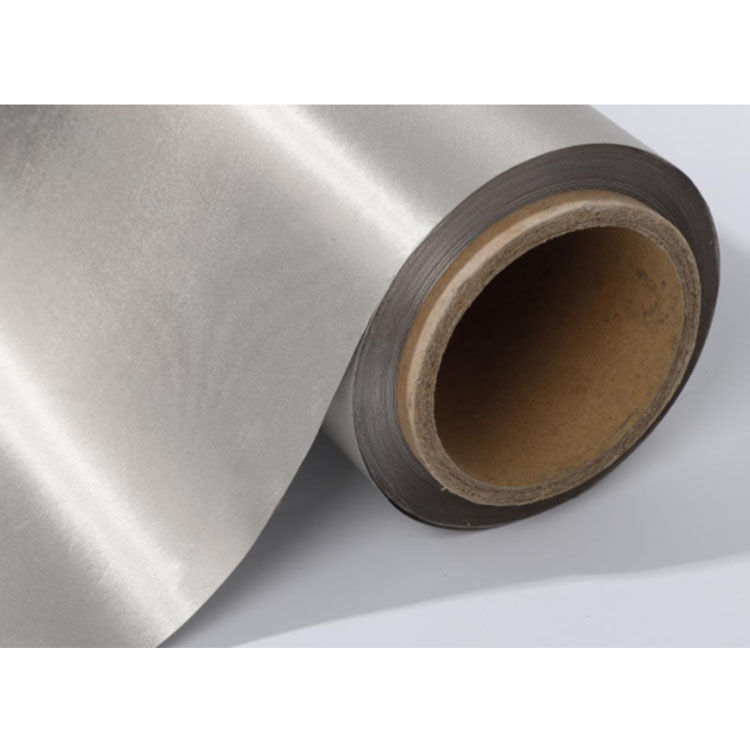

The structure of ITO conductive film is shown in the figure, which is composed of transparent glass/organic glass substrate, ITO conductive film, metal electrode, etc. ITO conductive film is mainly composed of two compounds, indium oxide and tin oxide, which are doped with nitrogen, tin and other elements to obtain suitable conductivity. Crystalline ITO conductive film is a type of conductive film that achieves better conductivity and mechanical stability by controlling the growth temperature and oxygen pressure of ITO thin film to make the size and distribution of ITO grains more uniform.

2. Preparation method of crystalline ITO conductive film

The preparation process of crystalline ITO conductive film is more complicated compared to amorphous ITO conductive film. The following introduces a method for preparing crystalline ITO conductive film by reactive magnetron sputtering.

(1) Bottom plate cleaning. Firstly, glass or organic materials need to be used as the bottom plate in an ultrasonic cleaning machine to remove surface grease, impurities, and other impurities, and then dried.

(2) Prepare ITO conductive film. Place the cleaned substrate in front of the target material of the vacuum magnetron sputtering device, and then perform magnetron sputtering reaction in an oxygen atmosphere. During the reaction process, it is necessary to control factors such as magnetron sputtering power, ion beam energy, and oxygen atmosphere to obtain the conditions required for thin film growth.

(3) Control the growth temperature. The temperature is controlled at around 350 ℃ -500 ℃, and a suitable oxygen atmosphere is maintained within this temperature range to achieve good crystallization effect of the film.

(4) Hot annealing. After the film preparation is completed, thermal annealing is performed to remove residual oxygen on the surface of the film and enhance the uniformity of grain size and distribution.

3. Characteristics of Crystalline ITO Conductive Film

Crystalline ITO conductive films are widely used in fields such as optoelectronic displays, touch screens, solar cells, LED lighting, etc. due to their better mechanical stability and conductivity. Its main characteristics are as follows:

(1) High transparency. ITO conductive film exhibits good transparency, making it widely used in transparent electronic devices.

(2) Good conductivity. The optimization of composition and structure enables crystalline ITO conductive films to have lower resistivity and better 3-level transparent conductivity.

(3) Stable chemical properties. Crystalline ITO conductive films have good corrosion resistance, heat resistance, and moisture resistance, and also exhibit stable electrical properties in different environments.

(4) Good mechanical stability. The improvement and optimization of the preparation process of crystalline ITO conductive film make it have better mechanical stability, which makes it have a wider application prospect and space.

4. Conclusion

Crystalline ITO conductive film is a new type of ITO conductive film, which has better mechanical stability and conductivity compared to amorphous ITO conductive film. Its conductivity and high transparency make ITO conductive films widely used in fields such as optoelectronic displays, touch screens, solar cells, LED lighting, and effectively promote the development of these areas.