Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

PET copper plated conductive film is a plastic film with high conductivity, characterized by:

1. Thin thickness, with a copper plating thickness of 0.05-0.15mm.

2. It has good conductivity.

3. Light transmittance up to 92%, resistivity 0.0007 Ω cm (glass paper)

4. High tensile strength, bending resistance, acid alkali resistance, and organic solvent corrosion resistance.

5. The surface hardness is greater than 8H and can be used within the range of -40~60 ℃.

6. Good electrical insulation performance.

PET copper plated conductive filmThe production process of PET film is as follows: first, the PET film is cleaned, degreased, and dried, and then a layer of conductive powder (copper powder) is coated on the surface of the PET film. Then, the conductive powder (copper powder) is uniformly coated on the surface of the PET film using a vacuum coating machine (the deposition of copper powder is a dynamic process mainly affected by metal particles and oxygen and moisture in the air). This process has achieved good conductivity and surface hardness.

Copper plated conductive film technology can not only increase the added value of products, but also enhance product performance and improve user experience. Compared to other processes, this process has the following advantages:

1. Copper plated conductive film has no damage to the surface of PET film.

2. Copper plated conductive film has a long service life and can be recycled.

3. Copper plated conductive film will not cause defects such as discoloration, reduced gloss, bubbles, etc. on the surface of PET film.

foreword

PET (polyethylene terephthalate) is a universal thermoplastic polyester resin widely used in packaging, building materials, light industry, chemical industry, automotive and other fields. During the PET film making process, metal electrodes such as copper or silver need to be plated onto it to achieve good conductivity. Due to the poor conductivity of copper, screen printing technology is generally used for copper plating on PET surfaces.

Screen printing technology is one of the earliest manufacturing processes applied to PET film. Due to the transparency and surface tension of PET film, in order to electroplate it, copper powder must be coated on its surface first, and then deposited on the PET film through a vacuum coating machine. Copper plating on a vacuum coating machine is a dynamic process, and the deposition rate and uniformity of copper powder are affected by factors such as metal particles, oxygen, and moisture in the air, resulting in uneven coating thickness. In order to eliminate problems during the copper plating process and improve the accuracy of copper plating, a secondary copper plating process is usually adopted, which involves coating copper powder on the surface of PET film first and then using a vacuum coating machine for copper plating.

Due to the disadvantages of uneven coating, inconsistent plating thickness, easy generation of bubbles, and surface deformation in the secondary copper plating method. Therefore, in-depth research has been conducted on the secondary copper plating technology. PET copper plating conductive film used in this paper is improved on the basis of secondary copper plating, which not only effectively eliminates the above shortcomings, but also has good conductivity, aging resistance and corrosion resistance.

This project uses the method of depositing copper powder on the surface of PET film to produce copper plated conductive film, in order to improve the accuracy of copper plating and enhance the surface quality of the coating, achieving uniform coating of conductive powder on the surface of PET film without electroplating. This project involves multiple technical fields such as equipment manufacturing, chemical plating, and electroplating.

principle

By surface modification, chemical plating, vacuum evaporation plating, electroplating and other methods, a layer of copper powder is deposited on the surface of PET, and then uniformly coated on the PET film using a vacuum coating machine. This is a new type of PET film conductive process. Its characteristics are:

1. The process is simple, easy to operate, and can be completed in one go without the need for secondary processing;

2. Does not affect the optical and physical properties of the product;

3. Uniform coating and good conductivity;

4. Low cost and long lifespan;

5. Can be recycled and reused, energy-saving and environmentally friendly;

6. It does not affect the electrical and mechanical properties of PET film, and will not cause damage to the substrate.

This process is suitable for PET materials, such as: PET/PET, PET/FPC, PET/PET, etc. This process has a wide range of applications. Such as various electronic products, instruments and meters, power and communication equipment, as well as medical and health care. The metals currently used as conductive films include nickel, iron, chromium, copper, etc. Copper plated conductive film is mainly used as the bottom layer in high-frequency printed circuit boards, on which circuits can be printed.

Copper plated conductive filmThe production process is as follows: cleaning → degreasing → drying → preparation of conductive powder → vacuum evaporation plating → water washing → vacuum condensation → water washing → drying → packaging.

1. Cleaning: It is the process of removing dust, grease, and other contaminants from the PET film, as well as removing excess moisture from the surface;

2. Oil removal: It is to make the surface clean, so as to facilitate subsequent coating and copper plating;

3. Drying: Allow the surface to reach a certain temperature before drying to ensure uniform coating and copper plating later on;

4. Preparation of conductive powder: Corresponding conductive powder can be selected according to product needs.

TECHNICAL INDEX

1. Conductive film thickness: 0.05-0.15 mm, film thickness uniformity ≤± 0.2 mm

2. Conductivity of conductive film: 0.0007 Ω cm

3. Resistance measurement: Glass paper (or fiberglass), standard measurement method is 1000 Ω

4. Surface hardness: ≥ 3H, no scratches on the surface

5. Copper powder purity:>99.5%; Particle size ≤ 10 μ m

6. Resistance to moisture and heat aging: 8 times; Resistant to dry heat aging twice

7. Corrosion resistance: Strong acids (sulfuric acid, hydrofluoric acid), strong bases, and organic solvents can all be used.

8. Dimensional stability:> 30 mm

9. Transmittance (%): ≥ 90%; Transmittance (%): ≥ 85%

10. Flatness: ≤ 5 mm, minimum deviation ≤ 1 mm

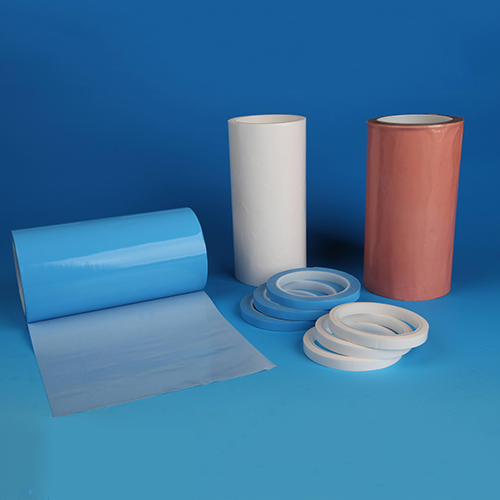

11. Packaging specifications: 200g/piece, 200g/roll, 1000g/roll, etc. The packaging forms include single-layer and multi-layer. Customized services can be provided according to user requirements.

12. Packaging standards: comply with national standards such as GB2312 and GB2315, as well as export standards to Europe and America. And strictly implement the relevant regulations on inspection and quarantine of foreign trade products, in compliance with RoHS standards.

13. Packaging label: Complies with the relevant provisions of the Implementation Rules for Green Product Certification in the Printing Industry, has passed environmental certification, and has corresponding environmental qualification certificates.

Process flow and operation points

(1) Process flow

1. Film preparation: PET film is subjected to high-pressure homogenization treatment through a high-pressure homogenizer, which improves the internal structure of the film and increases its mechanical strength;

2. Film degreasing: Treat the surface of PET film to remove oily substances attached to it and remove the oil film on its surface;

3. Cleaning: Use degreasers and other chemical solvents to clean the surface of PET;

4. Vacuum evaporation is the process of placing PET film in a vacuum coating machine and coating it under certain conditions to form copper powder on the surface of PET;

5. Drying: Use a vacuum dryer to dry the copper plating solution to ensure the quality of the copper plated conductive film;

6. Inspection: Inspect the copper plating solution according to technical requirements. To ensure the conductivity, service life, and reliability of the copper plated film.

(2) Operation points

1. Cleaning: The main purpose is to remove the oil film and organic matter attached to the surface of PET film to prevent contamination of the copper plated conductive film;

3. Evaporation: The vacuum evaporation method is applied to the surface of PET film, and copper powder is uniformly deposited on the surface of PET film through vacuum evaporation;

4. Drying: Slowly and evenly dry the copper plated conductive film;

5. Inspection: Inspect the copper plating solution through visual inspection, weighing, and adhesion testing;

6. Inspection: Check the copper plated conductive film according to technical requirements to see if there are defects such as bubbles and deformation. If there are defects, they should be dealt with in a timely manner;

7. Packaging and labeling: Pack and label the copper plated conductive film.

application area

1. The screens and casings of smartphones and tablets are usually made of transparent materials such as PET. When the metal or glass surface oxidizes or corrodes, poor contact or short circuit may occur. Copper plating on the metal surface has a good anti oxidation effect, which helps to improve its service life.

Backlight is one of the main components of display panels, and most materials used in the manufacturing process have high transparency. supportCopper plated conductive filmAttaching it to the backlight can provide high transmittance, thus improving the appearance of the product. Meanwhile, due to the absence of chemical reactions between the metal layer and PET material, the durability of the backlight can be improved.

Wireless connection is currently one of the most commonly used communication methods in the field of electronic devices. Due to the good processability of PET, copper plated conductive films can be used as antennas or reflective films. Due to its extremely high conductivity, transparency, corrosion resistance, and strength, copper plated conductive films can be used in the field of wireless communication.

4. The data center generates a large amount of high-temperature airflow and high-power electronic devices, such as servers, routers, and switches. When operating in these high-temperature environments, it can cause electronic components to age, fail, or be damaged, and increase surface temperature. Therefore, good electromagnetic shielding materials are needed in these high-temperature environments.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2