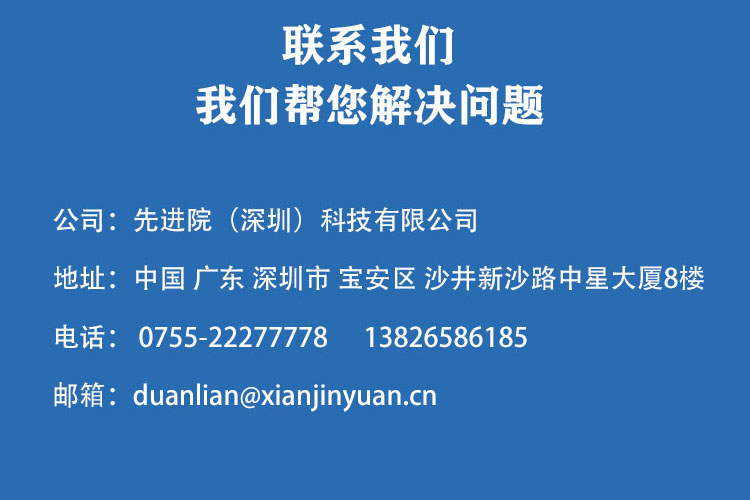

Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

In the field of modern military technology, stealth technology has become the key to enhancing the survivability and combat effectiveness of weapon systems. Among them,Absorbing coatingAs an important component of stealth technology, the improvement of preparation technology and compatibility research between infrared stealth coatings are of great significance for enhancing the stealth performance of weapon systems.

The preparation process of absorbing coatings involves multiple steps, and its core technology lies in selecting suitable absorbing agents and binders, and achieving uniform distribution and excellent performance of coating materials through fine process control. Firstly, according to the design requirements, select a suitable organic solvent as the base carrier for the coating. Subsequently, the binder and some deionized water were added to the organic solvent, stirred evenly, and allowed to stand to obtain the initial mixture. At this stage, precise proportioning and stirring conditions are crucial for ensuring the stability and performance of the initial mixture.

Next, the absorbing agent is uniformly dispersed in the initial mixture to obtain a homogeneous liquid with excellent absorbing properties. The type and content of absorber directly affect the absorption performance of the coating, so precise regulation is needed according to actual needs. Afterwards, glycerol, silica fume, and another portion of deionized water were added to the uniform solution, and stirred evenly again to form the final absorbing slurry.

Finally, the absorbing slurry is uniformly coated onto the backplate material, and after a curing process, a coating with excellent absorbing properties can be obtained. During this process, factors such as coating thickness, uniformity, and curing conditions will have a significant impact on the final performance of the coating.

Infrared stealth coating is a special functional coating used to weaken the infrared characteristic signals of weapon systems. Its main purpose is to reduce the brightness of aircraft in the infrared band, conceal or deform the shape of equipment in the infrared thermal imager, thereby reducing the probability of its detection and recognition. Infrared stealth coatings should have the required thermal infrared emissivity or strong temperature control ability, as well as a reasonable surface structure, low solar absorption rate, and compatibility with stealth coatings in other frequency bands.

In practical applications, infrared stealth coatings are widely used for surface coating of various military equipment to improve their stealth performance. Meanwhile, with the continuous advancement of technology,Infrared stealth coatingIt is also constantly being updated and upgraded to adapt to more complex battlefield environments and higher stealth requirements.

The compatibility study of absorbing coatings and infrared stealth coatings is an important topic in the field of military technology. In practical applications, these two coatings often need to work together on the same target object to achieve comprehensive stealth effects. Therefore, studying the compatibility between the two is of great significance for improving the stealth performance of military targets.

Research has shown that the design of a double-layer structure is an effective way to achieve good compatibility between absorbing coatings and infrared stealth coatings. By coating the surface of the radar stealth layer with an infrared stealth layer, it is possible to provide more channels for radar waves to penetrate the surface infrared stealth layer while ensuring low infrared emissivity. However, this design also faces some challenges, such as an increase in surface conductivity that may affect radar emissivity. To address these issues, researchers are exploring methods such as introducing wave transparent agents and structured design.

In summary, the preparation technology of absorbing coatings and the compatibility research of infrared stealth coatings are two important directions in the field of military stealth technology. By continuously improving preparation technology, optimizing coating performance, and conducting in-depth research on their compatibility, it is expected to provide more comprehensive and efficient stealth protection for military equipment, enhancing its survivability and combat effectiveness on the battlefield.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2