PET aluminum coated film is a common composite material that combines PET film with aluminum chemical vapor deposition technology to form a metalized PET film with excellent performance. This article will introducePET aluminum plated filmThe principle, preparation, performance, and application of.

1、 Principle

PET aluminum plated filmThe principle is to use chemical vapor deposition technology to form a layer of metallic aluminum on the surface of PET film, giving it metallization properties and high shielding performance. Chemical vapor deposition is a process of using high temperature and high vacuum environment to evaporate metal materials such as aluminum into steam, and then condense into a thin film on the surface of PET film. The process of PET aluminum plating film can be divided into steps such as PET film preparation, vacuum environment establishment, aluminum evaporation, and film condensation. In the preparation process of PET film, it is necessary to choose high-quality PET raw materials and form the film through processes such as plasticization, stretching, and calendering. In the process of establishing a vacuum environment, it is necessary to place PET film into a vacuum chamber and establish a high vacuum environment through methods such as pumping and heating. In the process of aluminum evaporation, the aluminum material needs to be heated to the evaporation temperature, and the evaporated aluminum vapor is deposited on the surface of the PET film to form a layer of metallization. In the process of film condensation, it is necessary to adjust parameters such as temperature and pressure to allow the evaporated aluminum vapor to condense into a thin film on the surface of PET film and form a layer of metallization.

2、 Preparation

PET aluminum plated filmThe preparation process requires controlling the temperature, pressure, evaporation rate of aluminum evaporation, as well as the temperature and pressure of film condensation, to ensure the quality and uniformity of the metallization layer. Generally speaking, the preparation process of PET aluminum coated film includes the following steps:

- Preparation of PET film: Select high-quality PET raw materials and form the film through processes such as plasticization, stretching, and calendering.

- Vacuum environment establishment: Place PET film into a vacuum chamber and establish a high vacuum environment through methods such as pumping and heating.

- Aluminum vapor deposition: Heating aluminum material to the evaporation temperature and depositing the evaporated aluminum vapor on the surface of PET film to form a layer of metallization.

- Thin film condensation: By adjusting parameters such as temperature and pressure, the evaporated aluminum vapor condenses into a thin film on the surface of PET film and forms a layer of metallization.

3、 Performance

PET aluminum plated filmThe performance depends on factors such as the thickness and uniformity of the PET film substrate and the metal aluminum layer. Generally speaking, the metal aluminum layer of PET aluminum plated film has good metallization properties and high shielding performance, which can effectively block the penetration of electromagnetic waves and light, protect the stability and safety of internal electronic devices. The thickness of the metal aluminum layer is generally between 20-100 nanometers and can be adjusted according to different application requirements. The uniformity and adhesion of the metal aluminum layer are also important indicators for evaluating the quality of PET aluminum coating.

4、 Application

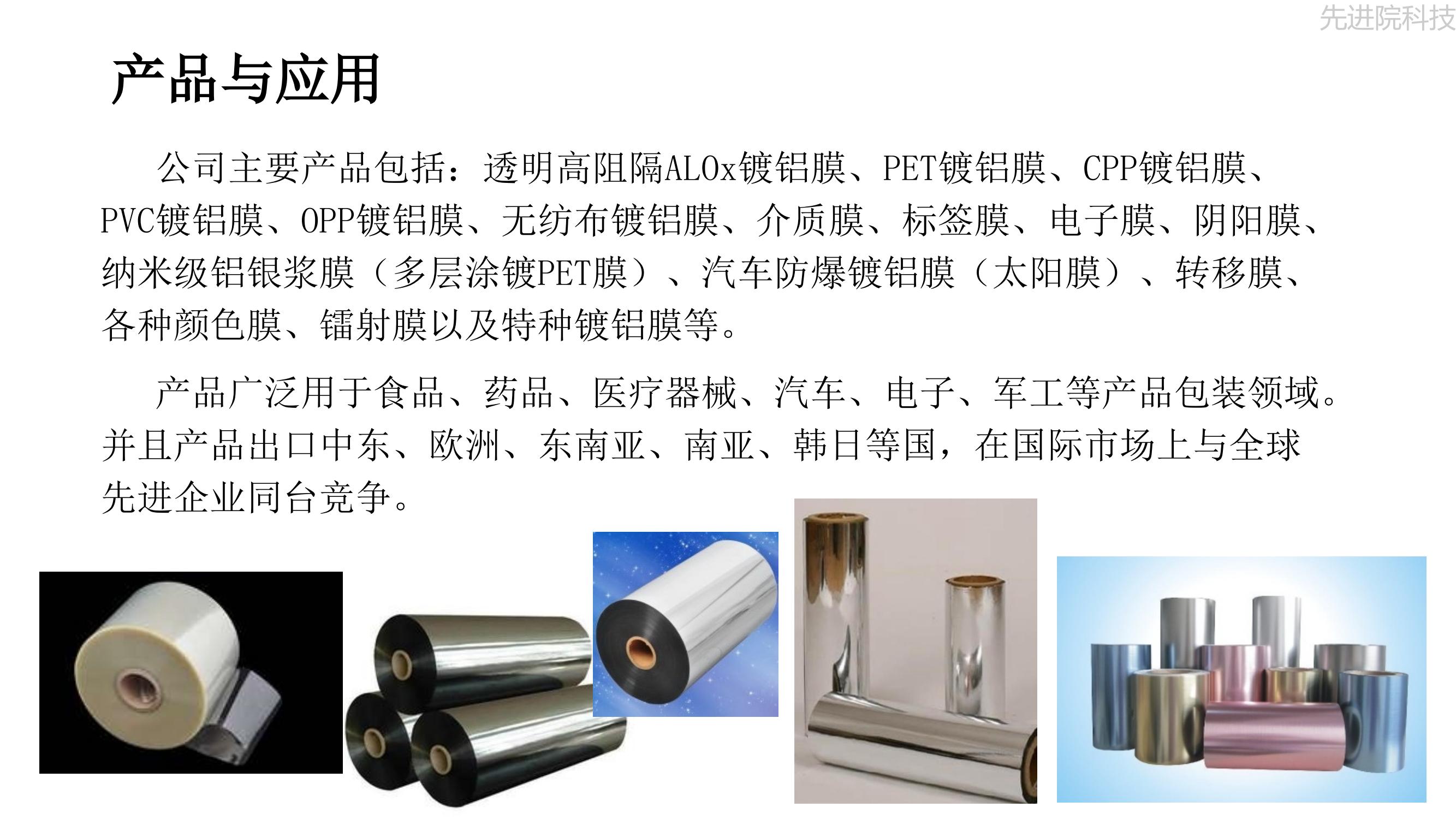

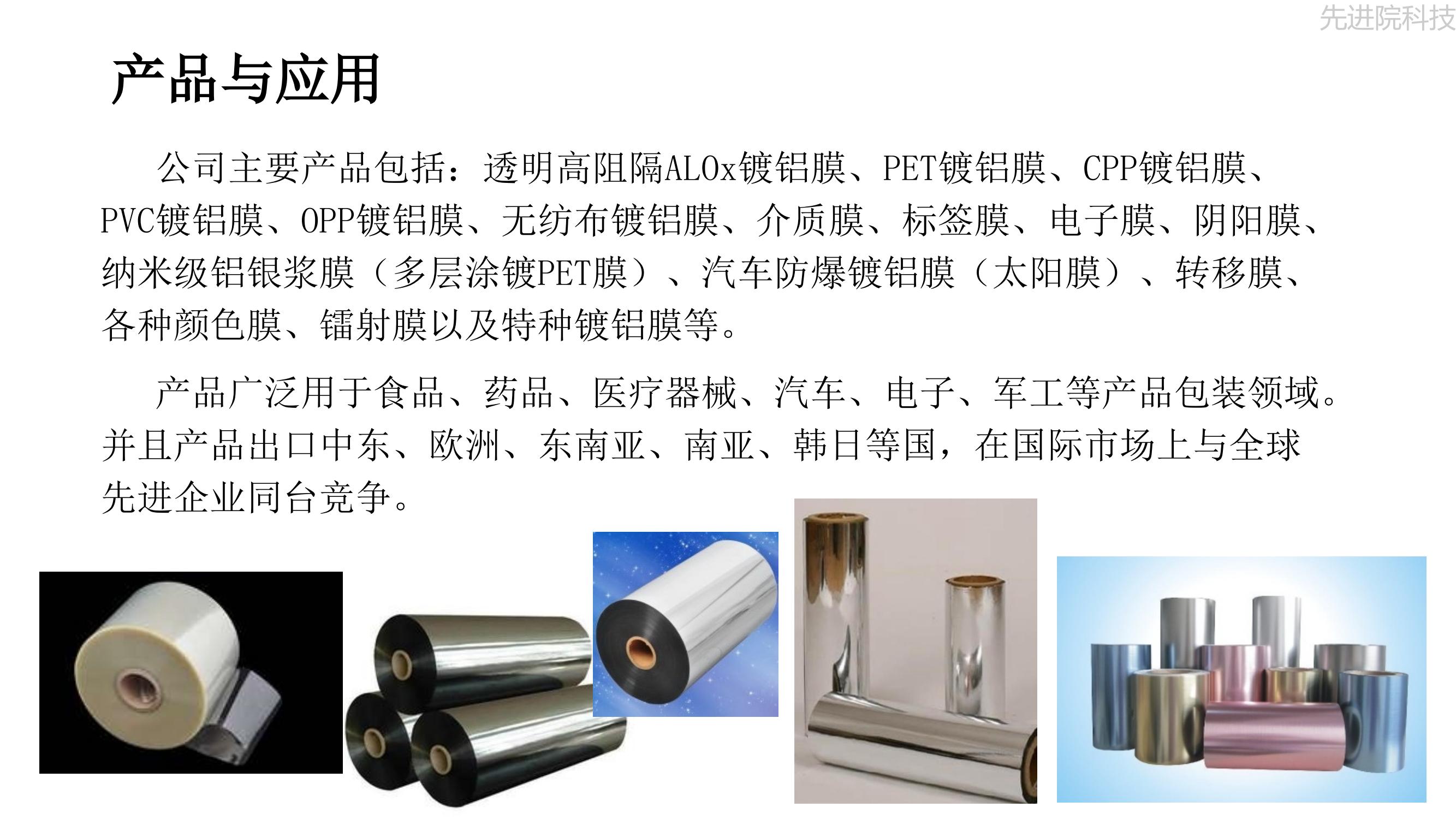

PET aluminum plated filmWidely used in packaging, printing, electronics, construction and other fields. In the field of packaging, PET aluminum plated film can be used to make various high-end packaging bags, boxes, bottles and other products, improving the beauty and freshness of the products. In the printing field, PET aluminum plated film can be used to produce various high-end printed products, such as business cards, posters, flyers, etc., to improve the glossiness and texture of printed products. In the field of electronics, PET aluminum plated film can be used to make electronic product casings, screens, keyboards, and other components, improving product stability and safety. In the field of architecture, PET aluminum plated film can be used to produce building glass, curtain walls, sunrooms and other products, improving the thermal insulation and aesthetics of building products.

In summary, PET aluminum coated film has broad application prospects and market space, and is a new type of composite material with important strategic significance.