Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

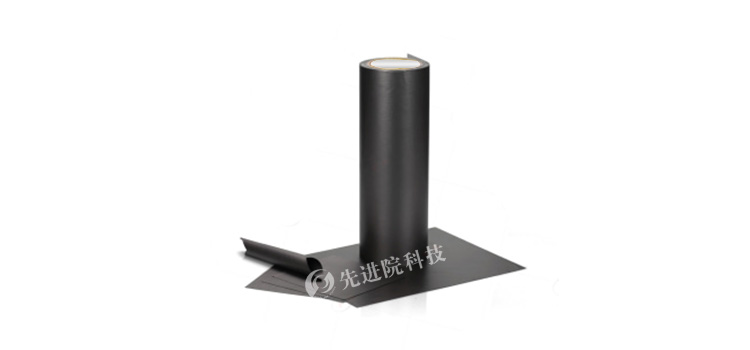

Carbon black absorbing materialIt is a material that utilizes the conductivity and microporous structure of carbon black to absorb electromagnetic waves. This material is widely used in microwave anechoic chambers, electromagnetic radiation protection, electromagnetic shielding of precision instruments and electronic devices. When manufacturing carbon black absorbing materials, it is necessary to strictly control multiple important parameters to ensure the performance and quality of the material. The following are important parameters that need to be controlled when manufacturing carbon black absorbing materials and their detailed explanations.

The carbon black content is one of the key factors affecting the properties of carbon black absorbing materials. The conductivity of carbon black can generate eddy currents when electromagnetic waves enter the material, converting electromagnetic energy into thermal energy. Meanwhile, the microporous structure of carbon black can absorb electromagnetic waves, reducing their reflection and transmission. Therefore, the selection of carbon black content has a significant impact on the absorbing properties of the material.

For example, in the preparationCarbon black loaded cobalt zinc ferrite absorbing materialBy adjusting the ratio of carbon black to metal salt solution, the absorption performance can be optimized. When carbon black is mixed with metal salt solution in a ratio of 1:1 by weight, good dispersion effect and absorption performance can be obtained.

The particle size distribution of carbon black has a significant impact on its dispersion uniformity and absorption performance in the matrix material. Carbon black with uniform particle size distribution can more effectively absorb electromagnetic waves and reduce their reflection. Therefore, when manufacturing carbon black absorbing materials, it is necessary to control the particle size distribution of carbon black to ensure its uniform dispersion in the matrix material.

The specific surface area of carbon black is another important parameter. Carbon black with high specific surface area can provide more surface sites, which is beneficial for the absorption and conversion of electromagnetic waves. In addition, carbon black with high specific surface area can enhance its bonding strength with the matrix material and improve the overall performance of the material.

The structure and morphology of carbon black also have a significant impact on its absorbing properties. The response of carbon black with different structures and morphologies under electromagnetic waves varies, so it is necessary to choose the appropriate carbon black structure and morphology according to specific application scenarios.

For example, Shenzhen Advanced Institute Technology Co., LtdResearch Platinum Brand Carbon Black Absorbing MaterialsAdopting unique structural and morphological design, it can exhibit good absorption effect over a wide frequency range.

The selection and ratio of matrix materials also have a significant impact on the performance of carbon black absorbing materials. Common matrix materials include plastic matrices such as polyethylene (PE), polypropylene (PP), and polyurethane (PU), as well as reinforcing materials such as fibers and ceramic powders. These matrix materials provide physical structure and deformation ability, while working together with carbon black to achieve absorption effect.

When preparing carbon black loaded cobalt zinc ferrite absorbing materials, ABS resin is used as the matrix material. By adjusting the ratio of carbon black to ABS resin, good absorbing performance can be obtained. For example, when the carbon black content in the matching layer is 1% and the carbon black content in the absorption layer is 5%, the reflectivity of the sample is all less than -10dB in the range of 2-18 GHz.

The manufacturing process and conditions also have a significant impact on the performance of carbon black absorbing materials. For example, in the preparation of carbon black loaded cobalt zinc ferrite absorbing materials, the solvothermal method is used. This process has the advantages of good chemical uniformity, high purity, simple process, low reaction temperature, and no need for calcination. By controlling the conditions of solvent thermal reaction (such as reaction temperature, reaction time, etc.), carbon black loaded cobalt zinc ferrite absorbing materials with uniform particle size distribution and good absorption performance can be obtained.

Shenzhen Advanced Institute Technology Co., LtdThe research platinum brand carbon black absorbing material adopts advanced manufacturing processes and conditions to ensure the high performance and stability of the material.

The important parameters that need to be controlled when manufacturing carbon black absorbing materials include carbon black content, particle size distribution, specific surface area, structure and morphology, selection and proportion of matrix materials, and manufacturing process and conditions. By strictly controlling these parameters, carbon black absorbing materials with excellent performance and good stability can be prepared. The research platinum brand carbon black absorbing material of Shenzhen Advanced Institute Technology Co., Ltd. is based on precise control of these parameters, achieving good absorbing effect in a wide frequency range and providing high-quality solutions for electromagnetic shielding and electromagnetic protection fields.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2