Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

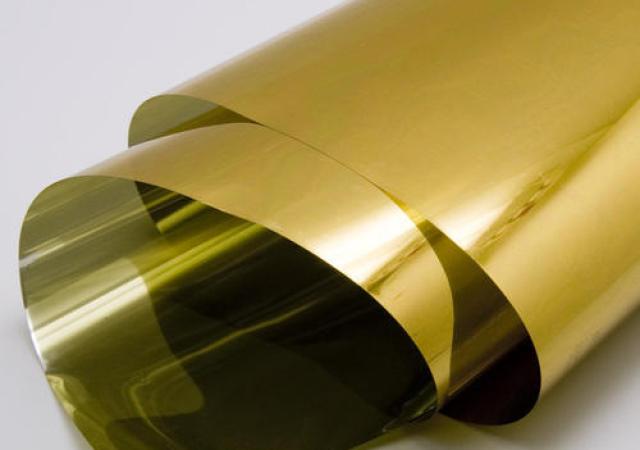

one kindDouble sided copper-clad LCP boardThe preparation method is characterized by comprising the following steps:, S00, Preheating treatment is carried out on the upper and/or lower pressure plates of the opposite laminating equipment. After the preheating treatment is completed, the temperature of the upper and/or lower pressure plates is ± 25 ℃ of the melting point of the double-sided copper-clad LCP plate; S01, Stack the first protective film, first copper foil, substrate film, second copper foil, and second protective film in sequence from bottom to top to obtain a stack; S1, Lay the stacked stack flat on the lower pressure plate of the surface pressing equipment; S2, Using the surface pressing equipment to sequentially pre press, pressurize, and hold the stack to obtain semi-finished products, wherein the holding time is 10 minutes and the holding pressure is at least 4 Mpa; S3, Performing air cooling treatment on the semi-finished product to obtain a finished product; In step S2, the pressure holding process includes an exhaust treatment process, which involves controlling the upper and lower pressure plates to open and close twice, with each exhaust lasting 2 seconds.

LCP film technology can be divided into three stages according to the commercial operation cycle: experimental sample, product (meeting requirements), and commodity (mature application). Due to the high technological barriers in LCP film preparation, the supply chains of LCP resin production companies and film companies are relatively closed, resulting in a scarcity of film preparation companies in the market. Currently, the main companies in the international market that master the core technology of LCP film preparation for antennas are Murata Manufacturing Co., Ltd., Keleli, and Chiyoda in Japan, while Murata Manufacturing Co., Ltd. and Keleli are able to reach the commodity stage.

At present, there is no domestic enterprise that can independently produce LCP film for antennas. Domestic manufacturers such as Waters Corporation, Pruitt, Jinfa Technology, and Ningbo Jujia are actively developing LCP resin and film products, but it will take a long time to produce LCP film products with mature applications in bulk. With the continuous promotion of R&D investment and process improvement by domestic enterprises, the bottleneck of mass production of LCP thin film materials for antennas is expected to be overcome.

Classification of LCP

Can be divided intoLyotropic liquid crystal polymerAnd thermally induced liquid crystal polymers. Liquid crystal polymers are in liquid crystal state in solvents, while thermally induced liquid crystal polymers are in liquid crystal state due to temperature changes.

tlcpIt emerged after lyotropic liquid crystal polymers, with excellent comprehensive properties and the ability to perform injection molding and extrusion molding processes. The main chain of liquid crystal polymer molecules is rigid, tightly stacked between molecules, and highly oriented during the molding process, resulting in a low coefficient of linear expansion, low molding shrinkage, and high load deformation temperature, some of which can reach over 340 ℃.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2