Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

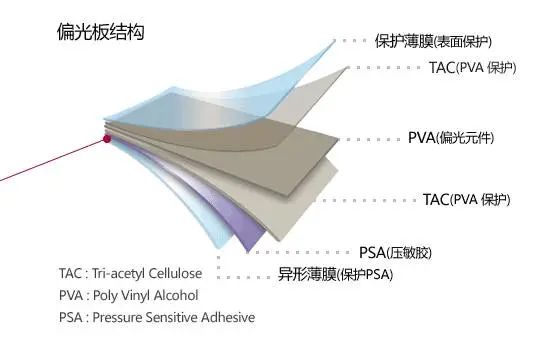

1.POL(Polaroid)

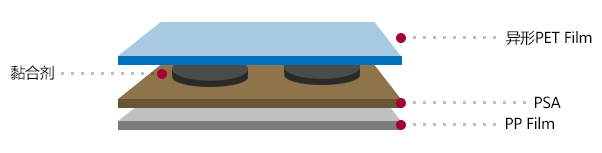

POL (Polarizer)It is one of the core materials of LCD (Liquid Crystal Display), which is an optical thin film that passes the light emitted from the LCD backlight in a single direction and cuts off the light in the other direction.

POL appearance

POL Structure Diagram

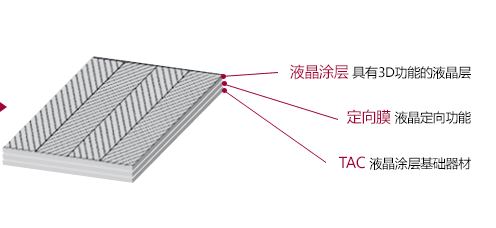

2.FPR(Film-type Patterned Retarder)

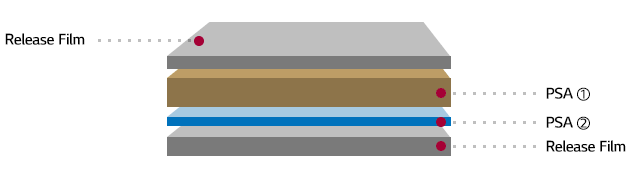

FPR film transforms images into independent left and right circles, and presents different images in both eyes through polarized glasses, making it the core optical material for achieving 3D.

FPR Structure Diagram

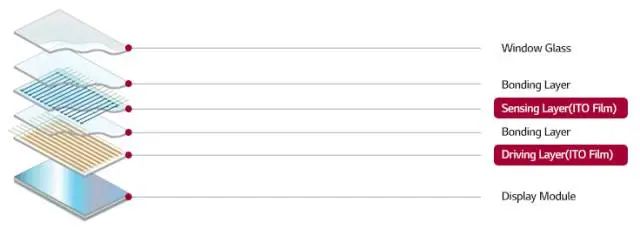

3.ITO(Indium Tin Oxide)

ITO film is a thin film made by electroplating indium (Indium) and tin (Tin) on a raw material film (PET or COP, etc.) through sputtering coating. It is the core material of touch panels.

ITO usage structure diagram

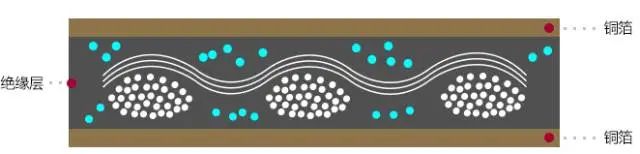

4.CCL (Copper Clad Laminate)

Providing circuit connections with semiconductor chips is also a substrate material for IC-PKG that protects them from external impacts.

CCL appearance

CCL Structure Diagram

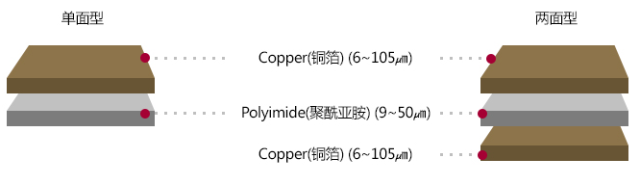

5.Layer FCCL(Adhesiveless Flexible Copper Clad Lamination)

Featuring outstanding heat resistance, internal chemical properties, and bending resistance, it is a flexible circuit substrate material used to achieve miniaturization and high integration of mobile devices such as smartphones and tablets.

Layer FCCL appearance

Layer FCCL Structure Diagram

6.DAF (Die Attach Film)

DAF is a thin film used in the manufacturing of semiconductor packages for the bonding of Die and Substrate, Die and Die.

DAF appearance

DAF Structure Diagram

7.FSA(Face Sealing Adhesive)

FSA is an OLED packaging material that greatly improves the lifespan of OLED displays.

FSA Structure Diagram

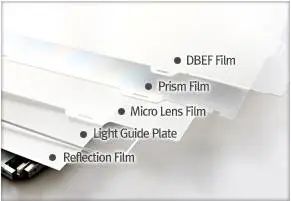

In addition to the above, optical film materials commonly used in backlight sources include diffusion films, brightening films, reflective films, and quantum dot films currently used on air vents.

8.Diffusion

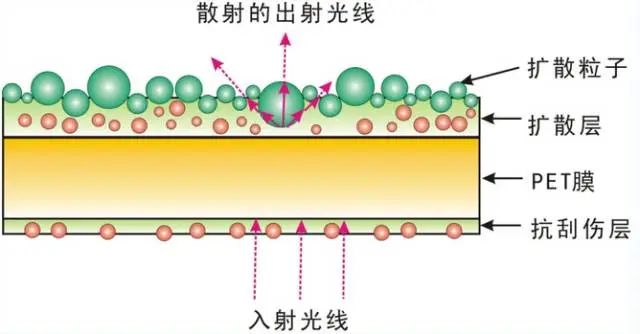

The diffusion film is mainly composed of three layers, including the bottom anti scratch layer, the middle transparent PET substrate layer, and the top diffusion layer. The diffusion membrane mainly plays a role in atomization.

Diffusion membrane structure diagram

9.BEF(Brightness Enhancement Film)

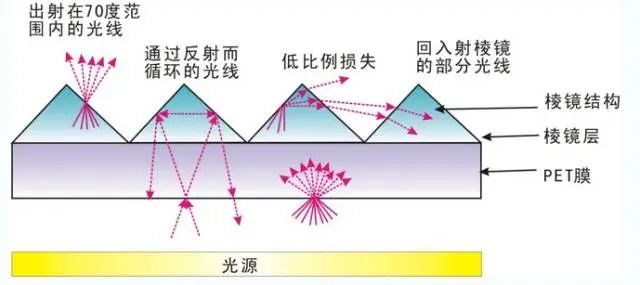

Brightening film, also known as prism film, is a process of adjusting the direction of light to achieve the effect of enhancing brightness based on the micro angular structure of its product. Brightening film is a transparent optical film composed of a three-layer structure. The bottom light entrance surface needs to provide a certain degree of haze through back coating, the middle layer is a transparent PET substrate layer, and the top light exit surface is a microprism structure.

Brightening film structure diagram

10.Reflector

Reflective film is usually placed at the bottom of the backlight module, mainly used to reflect the light that leaks through the light guide plate back to the panel side, thereby reducing light loss and increasing brightness.

Reflector appearance

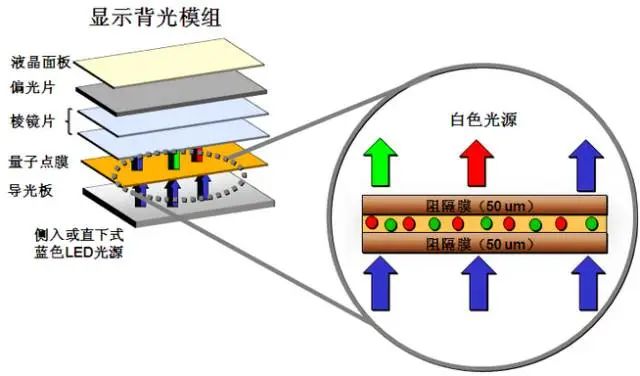

11.Q-DEF

Quantum dot thin film is a polymer film embedded with nano-sized spherical quantum dots composed of indium phosphide and cadmium, which can convert approximately two-thirds of the blue light emitted by the backlight into pure red and green light.

Q-DEF Structure Diagram

In the actual production of optoelectronic displays, a large amount of protective film and release film are also required. This type of product is made by coating a layer of resin adhesive layer on optical grade high transparency PET film through ultra precision coating technology. Including silicone adhesive series, polyurethane adhesive series, and acrylic adhesive series products.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2