Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

5G communication electromagnetic waves include two frequency bands, FR1 and FR2. The frequency range of FR1 is 450MHz to 6GHz, and the frequency range of FR2 is 24.25 to 52.6GHz. The FR2 frequency band belongs to the millimeter wave category, and the electromagnetic waves in this frequency band attenuate quickly in the air, requiring the adoption of ultra dense networking to achieve continuous network coverage. In the future, small and micro base stations will be deployed in densely populated areas. In order to prevent electromagnetic radiation from harming personal health, it is very important to perform electromagnetic shielding treatment on the base stations. This article briefly introduces the mechanism of electromagnetic shielding and common methodselectromagnetic shielding materialEmphasis was placed on analyzing the processing methods and related materials for electromagnetic shielding of communication base stations, and a brief summary was provided on the future development trends of electromagnetic shielding materials.

1、 Background of Mobile Communication Development

Mobile communication is a revolution in the telecommunications industry, which extends network terminals from fixed locations to individuals, allowing people to process and transmit information anytime, anywhere through mobile devices. The emergence of mobile communication has made information communication and transmission between people more timely, close, and frequent, revolutionizing people's production and lifestyle. In the era of the Internet of Things, traditional communication between people can no longer meet the needs of production and life. Communication between people and things, and between things, will become increasingly important and frequent.

Mobile communication has a history of 46 years since Martin Cooper, a former executive of Motorola in 1973, made the first mobile phone in history. The first generation of commercial mobile communication began in the late 1970s and early 1980s, when only simple analog voice communication could be achieved. In China, it was known as the "Big Brother". Subsequently, mobile communication will undergo upgrades and replacements approximately every 10 years. After more than 40 years of development, the form and functions of mobile phones have undergone earth shaking changes. In a certain sense, the development history of mobile phones is a magnificent history of mobile communication. At present, major countries around the world are accelerating the pace of 5G commercialization. On October 31, 2019, China officially announced the launch of 5G commercialization.

What unprecedented experiences will 5G communication bring to humanity? The International Telecommunication Union (ITU) has outlined three major application scenarios for 5G communication: enhanced mobile broadband, large-scale machine communication, and low latency and high reliability communication. Compared to 4G mobile communication technology, the significant change in 5G communication applications is the shift from communication between people to communication between people and objects, and between objects. In the 5G era, people can enjoy ultra-high network speed, the Internet of Things and smart communities can be truly realized, and industrial Internet and automatic driving will also come into reality.

5G communication does not simply emphasize peak transmission rate, but comprehensively considers eight performance indicators: peak rate, user experience rate, spectrum efficiency, mobility, time delay, connection density, energy efficiency, and energy density, as shown in Figure 2. In the above key performance indicators, 5G communication comprehensively surpasses 4G communication.

According to the definition of 5G frequency range by 3GPP, 5G communication includes two frequency bands: FR1 (i.e. Sub-6GHz) with a frequency range of 450MHz to 6GHz, and FR2 (i.e. Above 6GHz) with a frequency range of 24.25 to 52.6GHz. According to the above regulations, the wavelength range of electromagnetic waves in the FR2 frequency band is 5.7~12.4mm, which belongs to the category of millimeter waves. The large bandwidth of high-frequency millimeter wave spectrum is one of the reasons why 5G can achieve high-speed transmission. However, millimeter waves have shorter wavelengths, poor diffraction ability, and severe spatial attenuation of signals. To achieve commercial application of 5G communication, on the one hand, it is necessary to deploy more base stations to solve the problem of signal attenuation, and on the other hand, it is necessary to adopt a joint network of high frequency and mid low frequency to meet the different needs of users. In the 5G era, in order to meet higher mobile data demands, seamless and deep coverage of 5G networks will rely more on the deployment of miniaturized base stations. The radiation radius of small and micro base stations ranges from tens of meters to thousands of meters. In the future, a large number of small and micro base stations will be deployed in densely populated areas such as shopping malls, stations, airports, and enterprises. Table 1 provides an overview of various types of base stations and their application scenarios.

Communication base stations, also known as wireless base stations, are strategic infrastructure for achieving informatization. According to data released by the Ministry of Industry and Information Technology, as of September 2018, the number of mobile communication base stations in China was 6.39 million, and more base stations will be deployed for 5G ultra dense networking in the future. Electromagnetic radiation has become a focus of attention in the construction and operation of mobile communication base stations. When a base station is in operation, electromagnetic wave signals are transmitted into space by the transmitting antenna, which is the source of electromagnetic radiation from the base station. Electromagnetic radiation is a concern for public health, and countries around the world have strict regulations on electromagnetic protection for base stations. Due to people's lack of knowledge about the details of electromagnetic protection for base stations, they often turn pale when talking about base stations. In recent years, there have been extreme cases of obstructing the installation and damaging base stations in many places (see Figure 3).

According to Chinese laws, the construction of mobile communication base stations must comply with the requirements of the "Regulations on Electromagnetic Radiation Protection" and the "Environmental Electromagnetic Wave Health Standards". Only when the electric field strength meets the upper limit requirement of less than 12V per meter or the power density is less than 40mW/cm2, can it be considered compliant with safety standards. On January 1, 2019, the "Monitoring Method for Electromagnetic Radiation Protection of Mobile Communication Base Stations" issued by the Ministry of Ecology and Environment officially came into effect, highlighting the high importance that the country attaches to electromagnetic protection of base stations. At present, the world is accelerating the deployment of 5G mobile communication for commercial use, and the electromagnetic shielding treatment of mobile communication base stations and application terminals is particularly urgent.

2、 Electromagnetic shielding mechanism and basic principles of product design

When electronic devices are working, they do not want to be interfered by external electromagnetic waves, nor do they want to emit electromagnetic waves that interfere with external devices and harm human health. Therefore, it is necessary to block the propagation path of electromagnetic waves, which is electromagnetic shielding. The attenuation of electromagnetic waves during spatial propagation is mainly based on the reflection and absorption of electromagnetic waves:

(1) When electromagnetic waves propagate to the surface of the shielding body, they are reflected due to a sudden change in wave impedance at the interface between the air and the shielding body;

(2) After electromagnetic waves pass through the surface of metal materials, the metal materials will form eddy currents due to induced electromotive force. The eddy current magnetic field is opposite in direction to the original magnetic field and cancels each other out, thereby achieving shielding effect, that is, absorption loss;

(3) Electromagnetic waves that have not been attenuated within the shielding body, when propagating to another surface of the shielding body, undergo reflection again at the metal air interface with a sudden impedance change, and then return to the shielding body, resulting in multiple reflections.

As the frequency of electromagnetic waves increases, the proportion of absorption loss increases, while the proportion of reflection loss decreases. Therefore, for high-frequency electromagnetic shielding, eddy currents are mainly generated using high conductivity metal materials to counteract external electromagnetic waves. For low-frequency electromagnetic waves, materials with high magnetic permeability can usually be used to confine the magnetic field lines inside the shielding body and prevent electromagnetic wave diffusion.

The factors that affect the electromagnetic shielding effectiveness of materials include their electrical conductivity, magnetic permeability, and thickness. According to the mechanism of electromagnetic shielding, the design of electromagnetic shielding products can be based on the frequency band of the shielded electromagnetic waves, using materials with high conductivity or high permeability for development. Different forms of electromagnetic shielding materials can be made according to different application scenarios and processes, as shown in Table 2. At present, electromagnetic shielding materials widely used in the electronic information industry includeConductive paste, conductive adhesive, conductive coating, conductive paint, conductive rubber, conductive cloth, conductive foam, metal wire mesh, transparent conductive filmWait.

3、 Application of Electromagnetic Shielding Materials in Base Stations

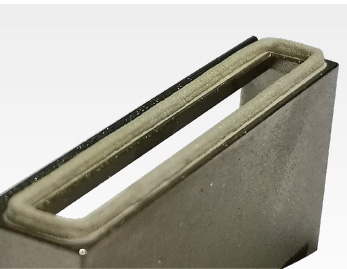

The base station casing is usually made of aluminum alloy die-casting parts. In order to achieve overall electromagnetic radiation protection, conductive silicone strips need to be used to connect the joints of the die-casting parts. The conductive silicone strip forms a continuous conductive body on the aluminum alloy base station shell, which restricts electromagnetic waves inside the base station through the eddy current effect and reflection effect of the conductive body, thereby preventing electromagnetic wave leakage and radiation. For 5G high-frequency communication, the electromagnetic shielding effectiveness of conductive silicone strips is mainly achieved through eddy current effect. The stronger the conductivity of the material, the more obvious the eddy current effect. Therefore, in order to improve the electromagnetic shielding effectiveness, the material needs to have higher conductivity. In addition to conductivity, conductive silicone strips must meet specific mechanical properties to meet practical application needs. For example, base station integrators have strict requirements for tensile strength, tear strength, elongation at break, compression permanent deformation, etc. The working environment of outdoor base stations is relatively harsh, such as prolonged high temperature, severe cold, humidity, and corrosive environment, which may cause deterioration of the performance of conductive materials. Therefore, conductive silicone strips must be able to withstand strict environmental aging tests.

In addition to using conductive adhesive strips to shield the base station housing as a whole, local electromagnetic shielding treatment is also required for electronic components inside the base station to prevent mutual interference of signals. Form in place (FIP) technology can accurately apply conductive adhesive to the desired areas, with a simple process that can form on complex surfaces and high material utilization. It is very suitable for local electromagnetic protection of base station equipment. Using FIP technology to apply conductive adhesive to the desired area, curing it to form a "wall" that is both conductive and elastic, thereby providing local shielding.

The commonly used electromagnetic shielding materials for communication base stations includeElectromagnetic shielding sealing strip, electromagnetic shielding conductive adhesive, electromagnetic shielding gasketInternational related companies include Laird, Norland, Gumei, etc., while domestic companies such as Zhongshi Technology and Feirongda. In terms of product performance, foreign companies have long monopolized the mid to high end electromagnetic shielding product market, while domestic companies have relatively poor product performance and are generally used for mid to low end products. In addition, domestic enterprises lack research and development capabilities and technological innovation capabilities, which cannot meet the increasingly high performance demands of terminal manufacturers. For example, the shielding of high-frequency electromagnetic waves in 5G has raised higher demands on the conductivity of materials, while users also have new requirements for the stretchability of rubber strips. Overall, the technological development level of domestic material manufacturers still needs to be improved urgently.

For high-frequency electromagnetic waves, the better the conductivity of the material, the greater the reverse eddy current generated, thereby weakening the interference of high-frequency electromagnetic fields. Therefore, the general idea for developing high-frequency electromagnetic shielding materials is to improve the conductivity of the material, which can be achieved by increasing the content of conductive materials or improving the conductivity of conductive powders. However, the improvement of conductivity of conductive powders has its own bottleneck, and considering the limitations of material viscosity and cost, the amount of conductive powder added cannot be too high. According to the electromagnetic shielding absorption loss formula, absorption loss is positively correlated with electrical conductivity and magnetic permeability. Therefore, using high magnetic permeability raw materials is also an effective and feasible solution. For example, the conductivity of nickel metal is slightly lower than that of precious metal materials such as silver, but its magnetic permeability is relatively high. Materials developed using nickel based powders also have shielding effectiveness comparable to silver based materials.

Advanced Institute Technology (Shenzhen) Co., Ltd. (hereinafter referred to as "Advanced Institute Company") is an electronic materials enterprise that cooperates with universities. Since 2017, it has been developing electromagnetic shielding paste and conductive adhesive products, mainly used in communication base stations and mobile terminals. In the field of consumer electronics, based on the development of conductive paste, a technical route of composite blending of sheet powder and ball powder has been proposed. The main mechanism is that sheet powder and ball powder have different specific surface areas and shapes. When these two types of particles with different sizes and shapes are mixed, they can greatly increase the conductive channels and bulk density. At the same time, through the combination of resin carriers and additives, a tighter bond between conductive materials is further achieved, reducing interface contact resistance and significantly improving their conductivity. In addition, after the sheet-like powder is wrapped in high elastic resin, it undergoes reversible deformation during stretching, so that the overlapping state of the conductive powder will not change after stretching recovery. Therefore, the electromagnetic shielding silicone strip prepared by Zhongkonatong Company has high stretchability, and the resistance remains basically unchanged after deformation recovery.

4、 Development prospects of 5G electromagnetic shielding materials including 5G conductive adhesive, silver copper conductive adhesive, nickel carbon conductive adhesive, and silver nickel conductive adhesive

A generation of materials creates a generation of industries. With the establishment of China's leading position in the field of mobile communication in recent years, enterprises represented by Huawei have established a voice in technology, standards, and other aspects. Domestic material and device manufacturers have begun to seize the opportunity to customize and develop materials for companies such as Huawei, providing a good opportunity for the development of new electronic materials in China.

In recent years, during the process of technical exchanges with industry clients, there has been some superficial understanding of the development direction of electromagnetic shielding materials in the future 5G field. The summary is as follows:

(1) The widespread application of centimeter wave and millimeter wave requires the development of electromagnetic shielding materials towards broadband direction, which requires the ability to cover the shielding of low - and high-frequency electromagnetic waves;

(2) The volume of future communication base stations and electronic components will decrease, requiring electromagnetic shielding materials to have lightweight and ultra-thin characteristics;

(3) Due to the emphasis on life and health, more and more electronic devices require electromagnetic protection, with stricter standards for electromagnetic shielding and higher requirements for shielding effectiveness;

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2