Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Advanced Institute Technology CompanyProfessional R&D and production of conductive adhesive series. If there are special usage processes, they can be developed separately. Please call for consultation.

Product Introduction

600 single componentConductive adhesiveModerate viscosity, high conductivity and thermal conductivity, enabling high thermal conductivity between the chip and the bracket. After curing, it has a low coefficient of thermal expansion, high adhesion, water resistance, oil resistance and other properties.

Product Application

Mainly used for high-power chips, fixing high-power crystal elements and brackets, suitable forAutomatic dispensing machineGlue dispensing with semi-automatic equipment.

Product performance parameters

| model |

600 |

test method |

| appearance |

silver gray |

visualization |

| viscosity range |

11000~14000mpa.s |

EHD viscometer |

| Chloride Cl- Sodium Na |

Ionics(Cl-、Na ) ≤0.8ppm |

Ion Chromatography Ion Chromatography |

| Tg |

100℃ |

TMA (Thermal Mechanical Analyzer) |

| Coefficient of thermal expansion |

34.5 μm/m•k |

TMA (Thermomechanical analyzer) |

| Thermal Conductivity thermal conductivity |

25 W/m·k |

Laser radiation laser radiation |

| Volume Resistivity Volume resistivity |

0.000002 ohm•cm |

Resistance meter Resistance meter |

| Cure condition curing process |

160℃ 60~70min |

Blast drying oven Blast drying oven |

| Hardness hardness |

80 (Shaw Brothers D) |

Hardness Tester Hardness tester |

| Die shear strength thrust strength |

≥14×107 (N/m2) |

Thrust Tester Thrust tester |

| Storage life @ -20℃ |

≥6 months |

Conduct testing on various indicators |

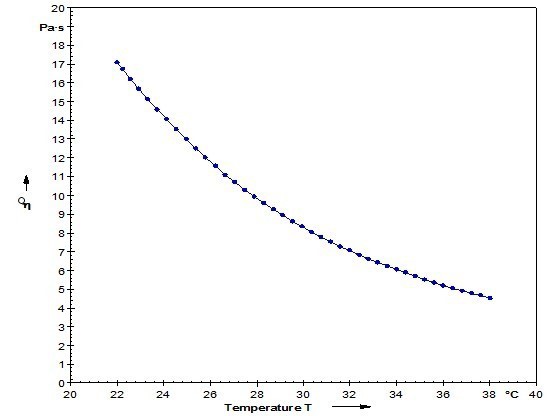

Fg1.600 rheological curve

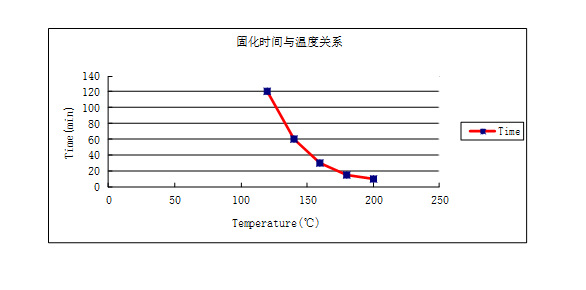

Fg1.600 curing temperature and time variation curve

matters needing attention:

1. Under freezing conditions, the glue must be warmed back to room temperature for at least 30 minutes before use;

2. This product operates for 48 hours at room temperature;

3. Suitable curing process can be selected based on the furnace temperature curve;

4. If the glue is not used up after being warmed up, it should be sealed in a timely manner and stored in a frozen state;

5. Do not mix with different types of adhesives.

Packaging specifications

10g/tube, 30g/tube, 100g/can.

instructions

1) After thawing, it should be immediately placed on the device in use.

2) If transferring the adhesive to the final formulation library, care must be taken to avoid trapping contaminants and/or air in the adhesive.

3) Use within the recommended lifespan of the product.

4) The dispensing amount needs to reach the required amount of adhesive for the corresponding size chip.

5) Spare quantities can be used according to application requirements.

Safety and protective measures

1) Untreated 600 is irritating to the skin and mucous membranes. Please avoid contact with the eyes or prolonged contact with the skin.

2) If it accidentally comes into contact with the eyes, please rinse with clean water for more than 15 minutes and seek medical attention immediately.

3) If discomfort occurs when in contact with the skin, please wipe it clean and rinse the skin with soapy water. When wearing contact lenses, if it is convenient to remove them, please remove the lenses. 600, which has been cured, may accidentally enter the eyes and combine with contact lenses, causing harm to the eyes.

4) Do not rub your eyes with your hands during use. Please take appropriate protective measures, such as wearing eye protection goggles.

5) Please pay attention to the ventilation measures in the workplace. Please avoid inhaling the gas it releases.

6) Please store it out of reach of children.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2