Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

1) Thermal conductivity coefficient

The thermal conductivity isTHERMAL GREASEOne of the important indicators of the application process is that most users lack instruments for directly testing thermal conductivity. They only test and verify the heat dissipation effect through whole machine testing, but this is only a temporary effect. For example, the required thermal conductivity is 1.0w/m.k, while the manufacturer provides 0.8w/m.k. From the user's whole machine testing, there may not be a significant difference, but after a long time of actual application, the thermal conductivity effect may not keep up, leading to premature product failure; When choosing an accurate thermal conductivity system, do not easily believe in theoretical values, but rather test actual values. When choosing a thermal conductivity coefficient, it is important to understand the parameters related to thermal conductivity, such as test area, heat flow rate, test thermal resistance, test pressure, average temperature, etc. If these parameters can be explained clearly, it indicates that the thermal conductivity of the thermal grease has been rigorously tested to prevent obtaining a thermal conductivity coefficient that is lower than the actual demand.

(2) Consistency

Consistency is an important indicator of the operability of thermal conductive silicone grease, generally characterized by fineness, viscosity, and penetration. Fineness requires the production of thermal conductive silicone grease without particles. The presence of particles can cause uneven contact surfaces and result in dryness, making it difficult to scrape flat; The higher the viscosity or lower the penetration of thermal grease with the same thermal conductivity, the more difficult it is to operate. Therefore, after confirming the thermal conductivity, it is necessary to compare the operability to avoid affecting production efficiency.

(3) High temperature aging

To ensure the reliable application of thermal conductive silicone grease within the expected service life of the product, it is necessary to understand two aspects of the weather resistance knowledge of thermal conductive silicone grease. One is the decay rate of thermal conductivity coefficient of thermal conductive silicone grease after aging; Secondly, what is the volatility and oil yield after aging; Once these are confirmed, it can be basically confirmed whether the thermal grease will fail prematurely during use.

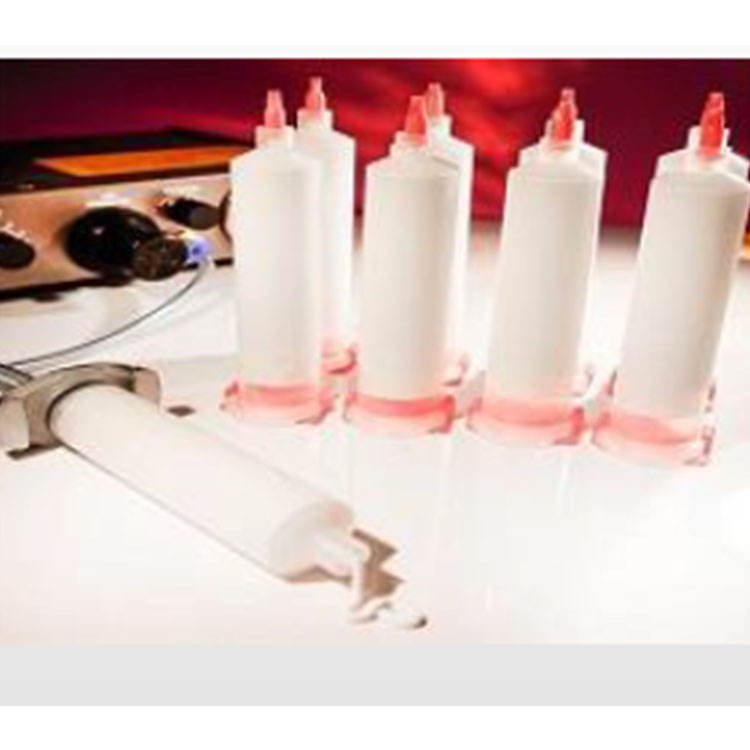

Most users choose thermal conductive silicone grease by purchasing it directly online. There is a relatively simple method for evaluating the stability of thermal conductive silicone grease after application, which does not require equipment and only requires observing the severity. The identification method is baking, and the purpose of baking is to simulate whether the various components of thermal conductive silicone grease will separate under high temperature for a long time, whether the weight will decrease, and whether the properties of the material itself will change, such as color. The more stable the performance of thermal conductive silicone grease, the milder the phenomenon of changes in high-temperature baking. Conversely, if it is unstable, the more severe the phenomenon of changes in various materials. The simple method is to take 5-10g of thermal conductive silicone grease and place it in a conical flask, cover it with a surface dish, and bake it at 150-200 ℃ for a period of time. Observe the oil halo phenomenon on the surface dish. The more severe the oil halo, the less stable the thermal conductive silicone grease will be in the subsequent application process. This is one of the identification methods.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2