Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Heat dissipation material (liquid metal thermal conductive silicone grease)

Product Introduction:Liquid metal thermal conductive silicone greaseIts fluidity and corrosiveness are superior to liquid metals, and its thermal resistance is significantly lower than that of ordinary thermal grease. Applied to the surfaces of different metals such as copper, aluminum, and nickel, and aged at 125 ℃ for 300 hours, its corrosiveness has significantly decreased compared to pure liquid metals. Liquid metal undergoes pump out verification, and no pores appear after 1000 cycles at -40~125 degrees Celsius.

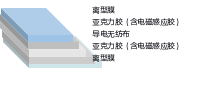

Product Introduction: Used in the frequency range of 100K Hz to 1G Hz, mainly used in RFID, NFC, and wireless charging fields to increase induced magnetic fields and eliminate metal eddy currents. It can also be used in fields such as IC chips, WIFI, and OLED displays to absorb attenuated electromagnetic waves and suppress noise interference.

High frequency absorbing materials

Product introduction: Used in the frequency range of 1G Hz to 100G Hz, mainly used in optical modules, high-speed data lines, millimeter wave radar, 5G communication, military equipment and facilities, radar and testing systems, etc., to eliminate electromagnetic wave interference, suppress cavity resonance, and reduce the effect of surface traveling waves.

Product Introduction: Compared to using copper foil andLow frequency absorbing materialLow frequency magnetic shielding materials can effectively block magnetic fields, mainly used in the frequency band below 100K Hz, and can shield the interference of low-frequency magnetic fields on sensitive devices, instruments, cables, display screens, and circuit boards. The commonly used thickness is 0.01-0.1mm, and the material can provide adhesive services according to user needs. The external dimensions can be processed according to requirements.

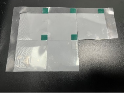

IC semiconductor tape

Product Introduction: 1) IC Grinding Tape: It has good adhesion to concave and convex wafers, good water resistance, and easy peeling after UV exposure. It protects the surface of the tape from damage caused by external foreign objects, cracking, and contamination such as dirt. 2) IC cutting tape: It has excellent adhesion and buffering properties to ensure the elimination of processing risks such as burrs and displacement during the cutting process. At the same time, its extremely low adhesion (after UV debonding) ensures that there are no residues on the die and that the next process can be smoothly flipped. IC Flip Solid Crystal Adhesive Tape: It has stable bonding performance, stable extensibility, and extremely low viscosity (after UV debonding) to ensure good flip yield and part yield

Product Introduction: Thermosetting heat activated tape and thermoplastic heat activated tape are widely used in consumer electronics structures, module or device bonding, adhesion, fixation, industrial structural bonding, automotive interior and exterior composite and structural component bonding. The process has a wide adaptability and can be processed into various pattern shapes through die-cutting. Customers can activate the adhesive film by heating and pressing, and bond the materials through pressing. It is suitable for bonding various substrates (PC/glass/stainless steel/fiber/synthetic leather materials, etc.) and has excellent bonding strength, chemical resistance, temperature and humidity aging resistance, and water washing resistance.

7.5w/mk phase change thermal conductive material

Product introduction: Comparison of phase change materials and thermal conductive silicone grease: Both are liquid materials above the phase change point, with extremely low thermal resistance; Below the phase transition point, the phase change material is a solid material, which is more convenient to operate and use; Phase change materials use longer organic molecular chains instead of shorter silicone oil molecular chains, resulting in low oil yield and long-term use that is not easily dried; The phase change material has an ultra-low thermal resistance of 0.07 ℃ * cm2/W in actual installation, and its technological level is internationally leading

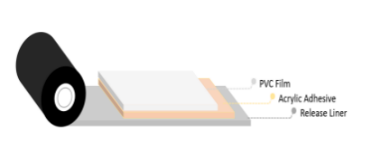

3D shading tape

Product introduction: Suitable for irregular surfaces or 3D surfaces, it can achieve shading (OD>6), insulation and other purposes. Thickness, material, function, etc. can all be customized.

Electric anti adhesive tape

Product introduction: Electric adhesive tape, widely used in LCD production process for screen protectors, transportation of electrical components, and fixing of mobile phone batteries. After the tape is powered on, it achieves the effect of reducing adhesion and can peel off the object being pasted.

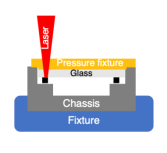

Laser activated adhesive tape

Product introduction: Compared with two mainstream bonding methods - pressure-sensitive foam adhesive tape and dispensing method, our laser activated adhesive tape has super bonding strength, narrow to 0.3mm, strong waterproof performance (IPX7), good impact resistance, excellent chemical resistance, and can realize heavy industry.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2