Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Characteristics of graphite sheet protective film

1. The graphite sheet protective film has good heat resistance, good flatness to improve the efficiency of customer use processes, and can be divided into strips according to customer requirements, with no burrs on the edges.

2. Product models with good heat resistance can be used for temporary fixation, shielding, and protection and transportation of film components during heating processes.

3. Can be processed into other products for supply.

4. In addition to acrylic adhesives, suitable heat-resistant silicone adhesives can also be selected according to their applications. Adhesive SUS plate 2kg drum b1 back and forth 5mm/s. The peeling angle of the tape is 180 °, and the peeling speed is 30mm/min.

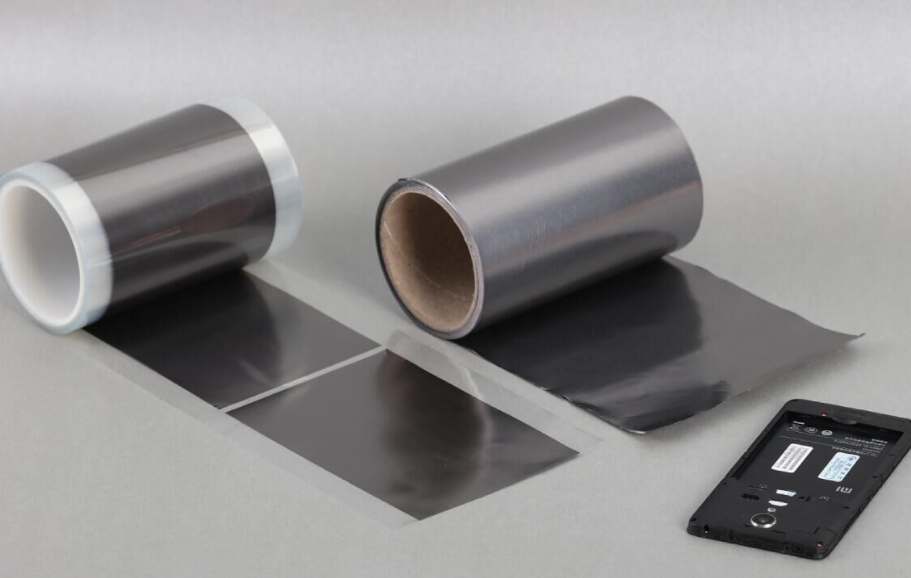

The graphite sheet protective film series is used for the transfer and pasting of heat dissipating graphite sheets after rolling, die-cutting process, and shipment protection.

�� Thousand level dust-free environment production, high product cleanliness

�� Stable peeling force, precise control of low viscosity range

�� Stable and excellent bonding performance for various graphite sheets

Scope of use

Mainly used in the QFNPACKAGE process, EMC resin sealing, PCB and FPC circuit board gold plating protection, and wave soldering fixation.

Carrier: Supports thin layer materials and provides protection during transportation.

Temporary fixation: used for temporary fixation operations in high-temperature production processes.

Covering: Covering during packaging production processes, etc.

Surface protection: Protect CCD glass.

Isolation: To prevent resin leakage during semiconductor packaging and electronic component molding.

Product Application

1. Transfer protective film

Graphite is prone to damage after extrusion molding. The back of PET silicone transfer film and the back of graphite play a load-bearing role in transportation, handling, and rewinding processes

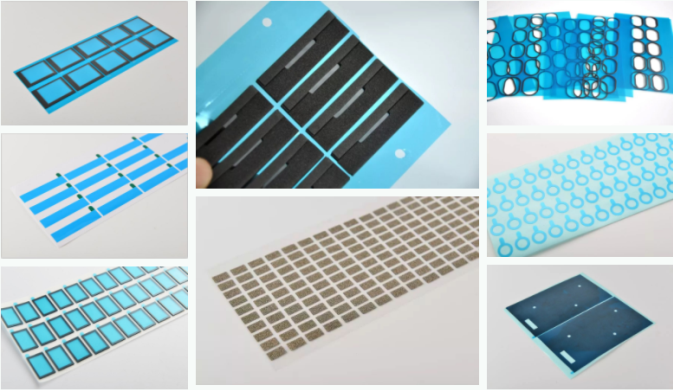

2. Die cutting process protective film

Used for graphite sheet die-cutting bottom and waste disposal, the precise viscosity control of the protective film can reduce the risk of defects caused by the waste disposal process on graphite sheets.

3. Shipping protective film

Shipping protective film is used for graphite shipping and transportation protection, and is attached to the back of ultra-thin single-sided adhesive.

Featuring excellent optical performance, the graphite surface can be inspected without the need for peeling.

Signal shielding: signal shielding for electronic devices with communication functions such as mobile phones, computers, and navigation systems

● Anti electromagnetic interference: Communication devices such as mobile phones and televisions, as well as electronic devices such as printers and scanners, are protected against signal interference

Thermal conduction and heat dissipation: All electronic and electrical devices such as mobile phones, computers, and televisions require thermal conduction and heat dissipation

Protection of graphene heat sinks during die-cutting process: such as satellite circuit heat dissipation, LED lighting heat dissipation, mobile phone/computer component heat dissipation, medical equipment heat dissipation, laser application heat dissipation

Protection of lithium batteries during the die-cutting process: such as new energy vehicles, household appliances, computers, mobile phones, electronic products, aviation lights, street lamps, and other products

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2