Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Release film, also known as delamination film, isolation film, or release film, refers to a thin film with surface separation properties. It is a plastic film that is subjected to plasma treatment, fluorine coating, or silicon release agent coating on the surface of the film material, such as PET, PE, OPP, etc., so that it can exhibit extremely light and stable release force for various organic pressure-sensitive adhesives. It is mainly composed of substrate, base adhesive, and release agent.

Classification of release film

According to different substrates, it can be divided into:

PE release film, PET release film, OPP release film, composite release film (i.e. the substrate is composed of two or more materials), etc.

According to the release force, it can be divided into:

Light release film, medium release film, heavy release film.

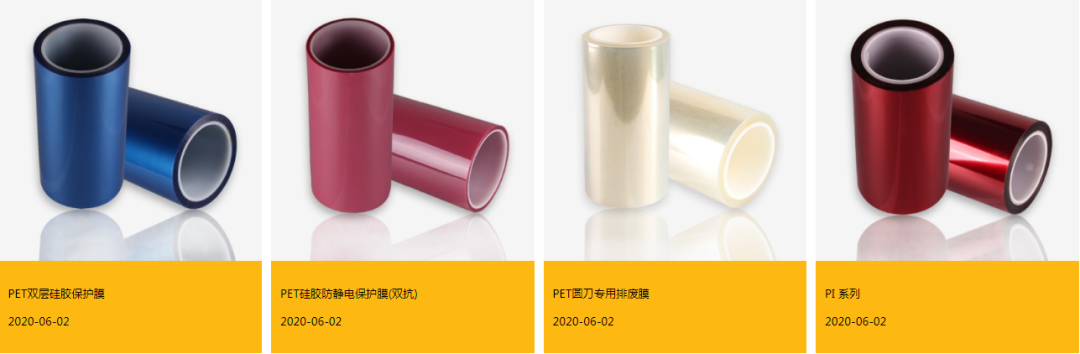

According to color, it can be divided into:

PET release films in various colors such as red release film, yellow release film, green release film, blue release film, etc.

According to surface treatment, it can be divided into:

Single sided release film, double-sided release film, silicon free release film, fluoroplastic release film, single-sided corona discharge, double-sided corona discharge, frosted release film, matte release film, etc.

According to the Si content, it can be divided into:

Silicon containing release film and silicon free release film.

According to material and purpose, it can be divided into:

Silicone oil film/release film - Polyester film (PET), polyester film, pre coated film, light diffusion film, color inkjet film (computer film), electronic industry specific printing film, frosted film, drawing film, white polyester film, black polyester film, PET/polyester film/PET film.

Application of release film combination

1. Packaging Decoration: PET release film can be treated with vacuum aluminum plating machine to form a metal luster aluminum plated cardboard. Its characteristic is that it has biodegradable and recyclable environmental properties, and is currently a newly developed green, novel, and advanced packaging material.

2. Transfer printing: PET transfer film, also known as PET transfer film, is characterized by its reusability. On the one hand, it can be applied in the printing field. PET release film can be used through special processes to heat and pressure transfer the printed patterns to objects made of glass, porcelain, plastic, metal, leather, cotton textiles, and other materials; On the one hand, it can also be applied to high-tech industries such as highly integrated chemical, plate making, vapor deposition, precision molds, and molding.

3. Protective film: PET release film can also be used in the production of PET protective film materials, so it can not only protect panels such as stainless steel, nameplates, and aluminum plates, as well as laptop casings and display screens, but also be used for process protection of electronic die-cutting, photoelectric die-cutting, electronic products, etc.

4. Reflective film: First class PET release film can be made into PET reflective film through special processes. It has excellent optical properties, thermal stability, and light aging resistance, and is mainly used in traffic reflective signs, billboards, and industrial safety signs with reflective requirements.

Test method for release force of release film

1. Take TESA 7475 tape with a width of 25.4mm and a length of 200mm and apply it to the test surface (release surface) of the film, and use a 2KG standard roller to roll it back and forth three times. (Note: Apply the tape completely while rolling it to avoid bubbles between the release film when applying the tape.);

2. After sticking the tape, let it stand for 20 minutes, and control the temperature and humidity in the laboratory at 23 ± 2 ℃ and 50 ± 5%, respectively;

3. Attach double-sided tape to the non test surface of the sample and fix it on a standard steel plate for testing;

4. Install the material onto the fixture and use a tensile testing machine to stretch the test tape at a 180 degree angle. The data displayed on the computer of the tensile testing machine is the release force (g/in) of the test piece. Take the average of 5 values as the test result.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2