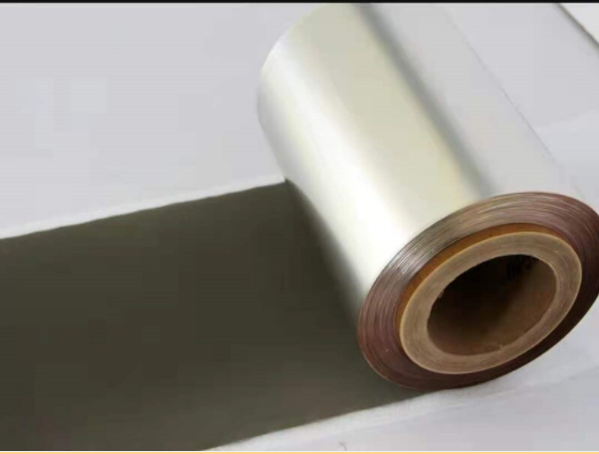

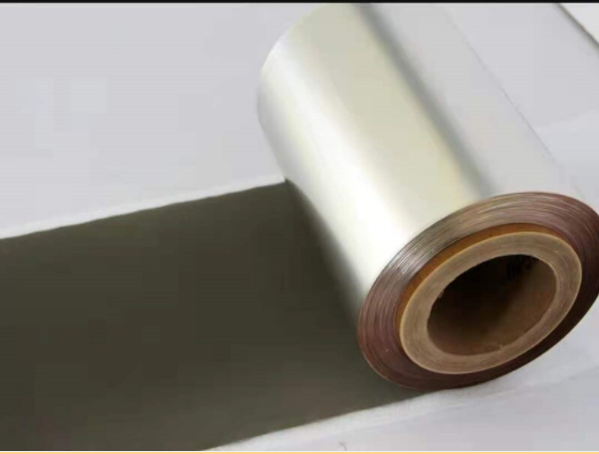

Copper foil nickel platingCopper foil tin plated film has been widely used as a surface coating in the field of metal corrosion protection One of the important research directions is to utilize the non-equilibrium properties of vapor deposition to form a supersaturated solid solution for nickel copper thin films, in order to improve their mechanical properties In order to explore the strengthening effect of Ti and N on aluminum based supersaturated solid solution composite films, a series of Ti: N ≈ 1 aluminum based composite films were prepared by magnetron co sputtering of Al and TiN. The effects of (Ti, N) content, sputtering temperature, and annealing process on the microstructure and mechanical properties of the films were studied The research results show that: 1. During room temperature sputtering, due to the non-equilibrium conditions of magnetron sputtering, Ti and N are respectively dissolved in the Al lattice in the form of substitution atoms and interstitial atoms. The (Ti, N)/Al composite film forms a double supersaturated solid solution with both substitution and interstitial solid solution characteristics The joint addition of Ti and N atoms significantly refines the grain size of the composite film, and with the increase of solute content, it transforms from nanocrystalline to amorphous structure Layered faults and twinning can be observed in the nanocrystals of the thin film, and solute atom enrichment zones can be formed at the grain boundaries The hardness of the composite film is at 17.1at.% (Ti, N) can quickly increase to 8.9GPa. 2. High temperature annealing studies have shown that annealing room temperature sputtered films at 250 ° C slightly increases the hardness of each film sample; After increasing the annealing temperature to 450 ° C, the hardness of the film decreased slightly Containing 6at.% When the room temperature sputtered thin film of (Ti, N) is heated to 430 ° C, the film transitions from a metastable state beyond saturation solid solution to a steady state. 3. After increasing the substrate temperature to 400 ° C,

High temperature sputtered thin filmThe hardness is slightly lower than that of the annealed state at 450 ° C The sputtered and annealed thin film samples at room temperature and high temperature all exhibit high elastic moduli of~120GPa Sputtering thin at room temperature and 400 ° C

Ti-Si-N nanocomposite coatings were prepared on single crystal silicon and hard alloys using multi arc magnetron sputtering technology with internal and external target configurations. The effects of substrate bias and Si target sputtering current on the coating structure and mechanical properties were studied. After experimental parameter optimization, Ti-Si-N nanocomposite coatings with Si atomic fraction of 6.3% were obtained under deposition conditions of bias voltage -150 V and Si target current of 15 A X-ray diffraction, X-ray photoelectron spectroscopy, and transmission electron microscopy analysis indicate that the coating contains crystalline TiN and amorphous Si3N4, with nano-sized TiN particles embedded in the amorphous Si3N4 matrix structure The nanohardness tester test shows that the microhardness of the coating is 40 GPa, and the frictional experiment shows that its friction coefficient is 0.89, which can meet the industrial application requirements of Ti-Si-N nanocomposite coatings