Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

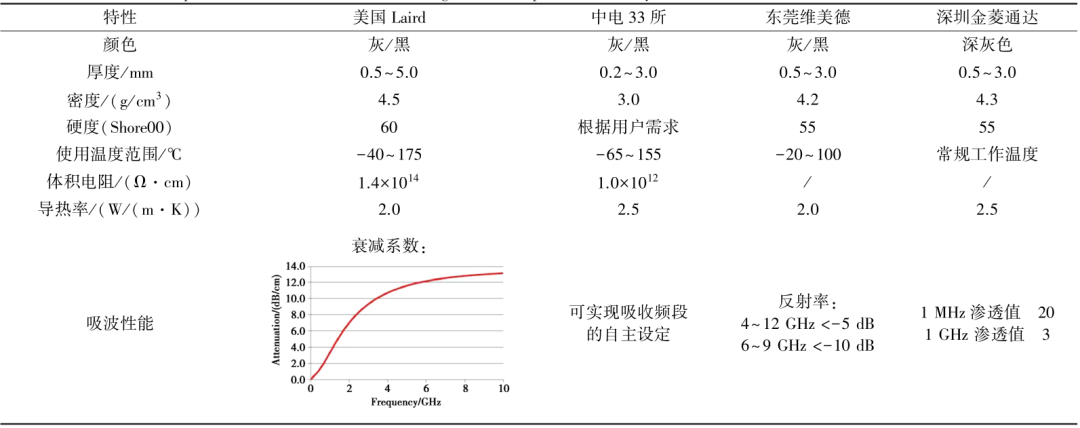

Based on the above technological foundation, domestic enterprises have gradually developed technologies suitable for large-scale preparation of thermal conductive absorbing materials. Ding et al. proposed using acrylic resin as the matrix material, alumina and zinc oxide as thermal conductive fillers, and ferrite and metal particles as absorbing components to obtain silicon free thermal conductive absorbing materials through mixed pressing. Lai et al. used solid silicone rubber as the matrix material and added different components of thermal conductivityAbsorbing powder fillerMix each component evenly according to the ratio and prepare it through compression molding processThermal conductive absorbing materialDue to the broad application market of thermal conductive absorbing materials in the field of electronic information, major electromagnetic protection material production units at home and abroad have independently developed thermal conductive absorbing functional powders, composite functional powders, and other methods to produce various types of thermal conductive absorbing material products, as shown in Table 3.

Table 3 Performance Comparison of Thermal Conductive Absorbing Materials in Recent Years

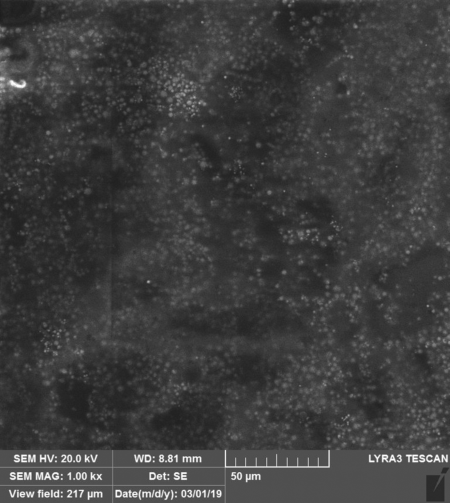

Foreign manufacturing enterprises not only evaluate the main technical parameters of materials (thermal conductivity, electromagnetic wave attenuation coefficient, density, etc.) in material composition design, but also consider the relevant requirements of specific usage environments (high temperature resistance, volatility, etc.), and design ternary or even quaternary composite functional filler formulas to achieve compatibility of thermal conductivity and absorption dual functions. In terms of process technology, it can be summarized as follows: functional powder preparation → multi class powder compounding → powder surface treatment → matrix polymer modification → component forward design → uniform dispersion → solidification molding → edge correction. Figure 3 shows a scanning electron microscope image of a certain type of thermal conductive absorbing material product from abroad. It can be seen that the material is filled with a large number of spherical particles inside. Through phase analysis, it is proved that its functional fillers mainly include zinc oxide, aluminum oxide, carbonyl iron, and aluminum silicon iron alloy.

Figure 3 Scanning Electron Microscope Photo of Thermal Conductive Absorbing Material

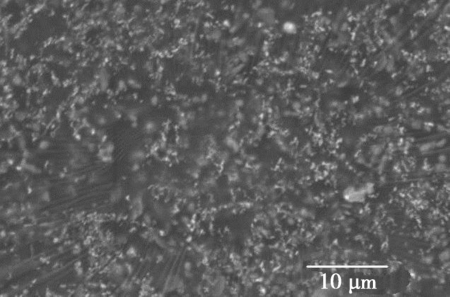

Based on the research foundation of domestic and foreign peer units, the author's unit combines its own main professional direction of electromagnetic protection to explore the preparation technology of high-performance thermal conductive absorbing materials. Through conducting multiple studies on material electromagnetic properties and thermal conductivity regulation, thermal conductive absorbing dual functional multi-component functional powder compounding, rubber based thermal conductive absorbing material molding control, etc., the author has mastered core preparation processes such as the compatibility design technology of electromagnetic wave attenuation characteristics and thermal conductivity function of silicone rubber materials, and the dispersion controllable method of composite functional fillers, breaking through the constraintsThermal conductive absorbing materialThe technical bottleneck of performance improvement has been achieved by regulating the dual functions of material thermal conductivity and absorption. The development of rubber based materials from single function to multifunctional integration has been completed, and high-performance thermal conductivity and absorption materials with completely independent intellectual property rights have been developed. The electron microscope images of typical products are shown in Figure 4.

Figure 4 SEM image of the thermal conductive absorbing material developed by the author's unit

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2