Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

After more than ten years of development,Thermal conductive absorbing materialThe production of industrial grade thermal conductive absorbing materials has become increasingly standardized and systematized, and their performance has steadily improved. They have been applied in the field of military and civilian electronic equipment, which requires people to deeply consider: the production and preparation technology of thermal conductive absorbing materials has made rapid breakthroughs, and there are still technical bottlenecks that have not been overcome, which restrict the development of the entire industry. Based on years of industry experience, Advanced Institute Technology believes that there are still four issues with thermal conductive absorbing materials.

The microstructure model and design theory of thermal conductive absorbing materials have not been established yet

Due to the fact that thermal conductive absorbing materials belong to the field of engineering application materials, the focus of research has always been on improving performance, that is, directly using different types and forms of functional powders for compounding, and improving performance by adjusting the addition amount. However, there has been no in-depth study on the interaction mechanism between different fillers from a microscopic level. Thermal conductive absorbing materials are generally composed of a matrix polymer material and various functional fillers. There is no corresponding physical model or guiding theory for the influence of the composition, addition amount, microstructure, and distribution state of functional fillers on the electromagnetic properties and thermal conductivity of the material.

Based on the traditional thermal conductivity enhancement phase "sea island" structural model and electromagnetic wave absorption mechanism, the composition design of thermal conductivity absorbing materials has significant errors between theoretical design expectations and actual test results, and theory cannot effectively guide practical production. Therefore, the lack of material microstructure and functional unit models, the disconnect between theory and industrial production, and the blank guidelines for the composite use of multiple functional fillers seriously constrain the development of basic design theory for thermal conductive and absorbing materials.

The performance evaluation and testing standards for thermal conductive absorbing materials have not been unified yet

Thermal conductive absorbing materialThe most important performance indicators are thermal conductivity and absorption performance. At present, there are significant differences in evaluation indicators, testing principles, testing methods, and testing standards between these two performance indicators within industry units. The testing data between them varies greatly, resulting in a lack of rules and regulations for the development and use of such products, which seriously restricts their promotion and application. The specific analysis is as follows.

Thermal conductivity

At present, the industry mainly adopts the following two testing standards for the thermal conductivity of thermal conductive absorbing materials: (1) American standard ASTM D5470 "Standard Test Method for Thermal Transmission Characteristics of Thermal Conductive Electrical Insulation Materials"; (2) Chinese standard GB/T22588-2008 "Flash method for measuring thermal diffusivity or thermal conductivity".

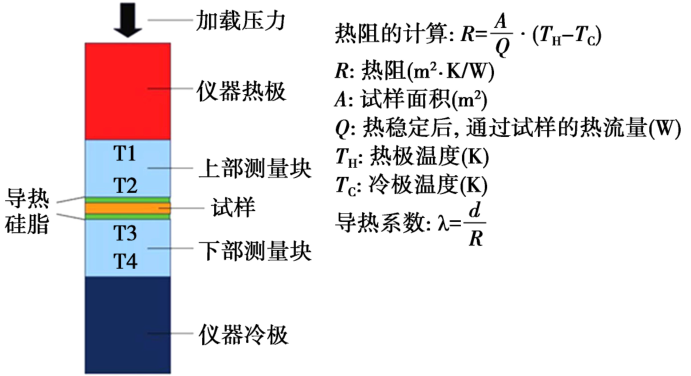

Figure 5 Schematic diagram of the basic structure of ASTM D5470 thermal flow testing device

Figure 5 is a schematic diagram of the basic structure of the ASTM D5470 thermal flow method testing device. The testing principle is to apply a certain amount of heat flow and pressure to the sample to test its thickness and the temperature difference between the hot and cold plates, in order to obtain the thermal conductivity of the sample. This testing method can better simulate the actual usage state and is closer to the actual usage scenario. GB/T22588-2008 is equivalent to the American standard ASTM E1461 "Test Method for Determining Solid Thermal Diffusivity by Flash Method". It uses high-intensity energy pulses to irradiate small and thin disk specimens for a short period of time. The value of thermal diffusion coefficient is calculated by the thickness of the specimen and the time required for the low-temperature surface temperature to rise to a certain value. The actual measured data is the thermal diffusion coefficient of the material, and the formula for calculating its thermal conductivity coefficient is λ=α · Cp ·ρ (α is the thermal diffusion coefficient, Cp is the specific heat capacity, and ρ is the bulk density).

In many literature, it has been proposed that the results of ASTM D5470 and GB/T22588-2008 testing methods are relatively close, and it is believed that the two results can be used interchangeably for comparison. The author believes that there is a significant difference between the two testing methods. From the testing method, it can be seen that ASTM D5470 can eliminate the interface thermal resistance factor by testing the fitting curves of three samples with different thicknesses, reflecting the thermal conductivity in use, while GB/T22588-2008 is a laser flash method that reflects the internal thermal conductivity of the material itself, but does not consider the influence of interface contact thermal resistance. Therefore, it cannot be simply assumed that the results are close enough to confuse the two testing standards. Based on long-term work experience, the author believes that ASTM D5470 is more suitable for testing the thermal conductivity of gasket products such as thermal conductive absorbing materials.

microwave absorbing property

At present, the measurement of thermal conductivity and absorbing materialsElectromagnetic wave absorption performanceMainly through two indicators: (1) reflectivity; (2) Electromagnetic wave attenuation coefficient.

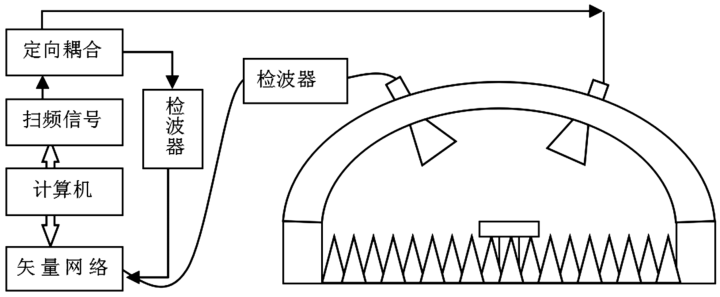

(1) Reflectance. According to GJB 2039A-2011 "Test Method for Reflectivity of Radar Absorbing Materials", the electromagnetic wave absorption performance of thermal conductive absorbing materials is directly tested. This method is the most widely used method for evaluating the performance of absorbing materials in China. During the test, the electromagnetic wave signal is transmitted by a network analyzer through an antenna, and the signal is incident on the test sample and reflected out. The reflected signal is received by another antenna and sent to the network analyzer. Due to the effect of absorbing materials, there is a certain difference between the transmitted power and the received power. This difference is converted into a value in dB, which is the reflectivity of the sample. The testing system is shown in Figure 6.

Figure 6 Schematic diagram of bow shaped sweep frequency measurement system

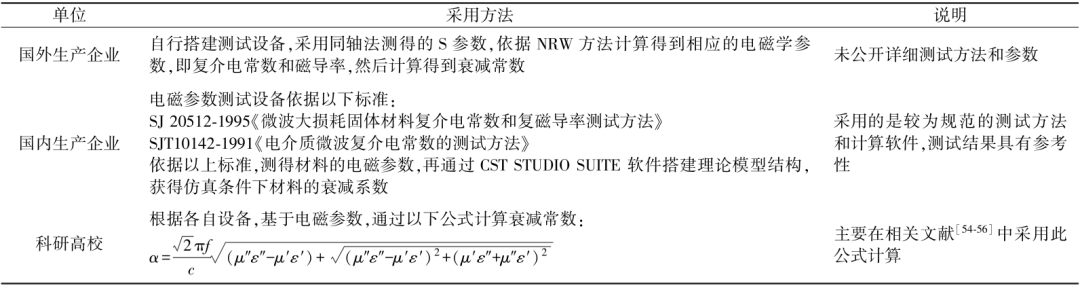

(2) Electromagnetic wave attenuation coefficient. The electromagnetic wave attenuation coefficient is a theoretical property that is not used to indicate the performance of a material in a microwave device, but is calculated based on the composite dielectric constant and composite magnetic permeability of the loss material. It is a rigorous method for comparing the performance of two absorbing materials. The electromagnetic wave attenuation coefficient can intuitively reflect the attenuation of electromagnetic clutter inside the device during the use of materials. Relevant researchers and production enterprises have gradually adopted this index to measure the performance of materials. However, there is currently no testing standard for this index at home and abroad. Each unit conducts testing according to its own hardware conditions, and the specific methods are shown in Table 4.

Table 4 Testing Method for Electromagnetic Wave Attenuation Coefficient

Advanced Institute of Technology believes that due to the fact that reflectivity is mainly used to measure the absorption performance of flat plate materials, the distance between the test source and the absorption material is far, which differs greatly from the actual use scenarios of thermal conductive absorption materials. The test results tend to reflect the absorption performance of the material more accurately, and cannot accurately characterize the attenuation of electromagnetic clutter by the material inside the device. Therefore, the electromagnetic wave attenuation coefficient is more suitable for evaluating the absorption performance of thermal conductive absorption materials.

In summary, currentlyThermal conductive absorbing materialThere are still many types and standards of testing standards for main performance indicators, and there are many problems caused by weak industry norms in the actual development and production process. Due to the lack of unified and specialized testing methods and standards for the performance of thermal conductive absorbing materials, various units have obtained significantly different results using different testing methods, resulting in a lack of unified standards for evaluating the main performance of thermal conductive absorbing materials. This has led to poor guidance for subsequent equipment designers in the selection, use, and evaluation of thermal conductive absorbing materials, a lack of product standards, weak universality, incomplete product processes and quality input factors, and has constrained the standardized development of the industry.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2