Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

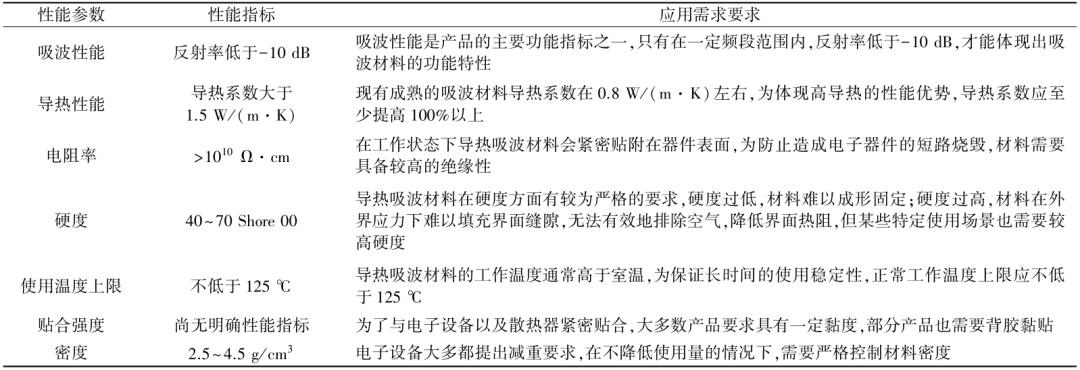

In recent years, electronic devices represented by semiconductor components have become increasingly smaller in size and generate higher heat, while the accompanying electromagnetic interference problem has become more and more serious. useThermal conductive absorbing materialIt can effectively reduce the operating temperature of electronic components and reduce or shield the electromagnetic noise generated by them. Based on market demand, the industry has summarized the basic performance characteristics that thermal conductive absorbing materials should possess, as shown in Table 1.

Table 1 Performance Requirements for Thermal Conductive Absorbing Materials

1.1 Experimental Exploration Stage

The overall research and development concept of thermal conductive absorbing materials is roughly the same, which is to add functional fillers to the polymer matrix to make the material have thermal conductivity or absorbing function. Absorbing materials usually add ferrite, carbonyl iron, hydroxy iron, hydroxy nickel, hydroxy cobalt, conductive polyaniline, barium titanate, graphite, carbon fiber and other absorbing agents to the matrix to achieve excellent absorbing performance, but the thermal conductivity between the filler and the matrix is generally low. At present, thermal conductive materials mostly use insulation fillers such as alumina, magnesium oxide, aluminum nitride, silicon nitride, boron nitride, etc., which do not have absorbing function. Each research and development unit usually conducts thermal conductive materials in the early stageAbsorberBased on the research, a material with both thermal conductivity and absorption functions was obtained by mixing traditional thermal conductive fillers and absorbers into the matrix material.

However, due to the upper limit of the total amount of functional fillers added in rubber and other matrix materials, an increase in the addition of one type of filler (thermal conductivity, absorption) will inevitably result in a decrease in the addition of another type of functional filler, leading to a contradiction between the thermal conductivity and absorption performance of the material, making it difficult to achieve synchronous improvement of the material's thermal conductivity and absorption performance. At present, the research and development of thermal conductive absorbing materials can only balance the two performance indicators of thermal conductivity and absorption by comprehensively coordinating the addition ratio of two fillers, which cannot meet the requirements of sensitive electronic devices for materials to have both electromagnetic wave absorption function and efficient thermal conductivity.

The research and development methods of thermal conductive absorbing materials are relatively simple and conventional, but the prepared thermal conductive absorbing materials are difficult to achieve compatibility between efficient thermal conductivity and strong electromagnetic wave absorption. Starting from the development concept of single functional materials for thermal conductivity and absorption, domestic and foreign scholars have searched for the causes of problems and found that in the process of material microstructure design, it is necessary for the absorbing components inside the material to be fully dispersed and isolated to improve the absorbing effect and broaden the frequency range. To improve the thermal conductivity of the material, high continuity and low defects inside the material are required to form a thermal pathway network structure, which leads to design contradictions in the thermal conductivity and absorption applications of the material in terms of structure. In particular, the addition of thermal conductive fillers can also affect the performance of the absorbing agent, which is not conducive to the design of the material's absorbing performance, increases the difficulty and cost of the development of thermal conductivity and absorbing materials, and prolongs the development cycle. Meanwhile, thermal conductive absorbing materials are mainly composed of thermal conductive fillers, absorbing agents, and rubber polymer matrices. When the content of thermal conductive and absorbing agents is high, it will bring many problems such as increased viscosity, difficult molding, and increased cost, which will affect their practical application.

In response to the multiple factors that affect the thermal conductivity and absorption properties of materials, and the cross interaction between different factors, scholars in this field have studied the influence relationship between functional filler components, particle size, structural parameters, and molding process parameters, comprehensively analyzed the combined effects of various factors on material properties, and attempted to obtain practical guidance mechanisms and methods for regulation.

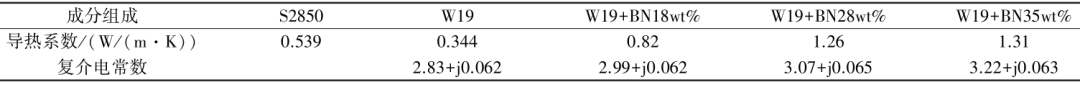

Zivkovic et al. used boron nitride (BN) as a functional filler and utilized the high thermal conductivity and adjustable electromagnetic parameters of BN to prepare epoxy resin based materials with both thermal conductivity and absorption functions. The materials were directly added to the powder, mechanically mixed, and cured at high temperaturesEpoxy resin based thermal conductive absorbing materialThe thermal conductivity and electromagnetic parameters of the final prepared material are shown in Table 2, which were compared with the performance of existing mature products.

Table 2 Thermal conductivity and complex dielectric constant of epoxy resin loaded with different BN contents

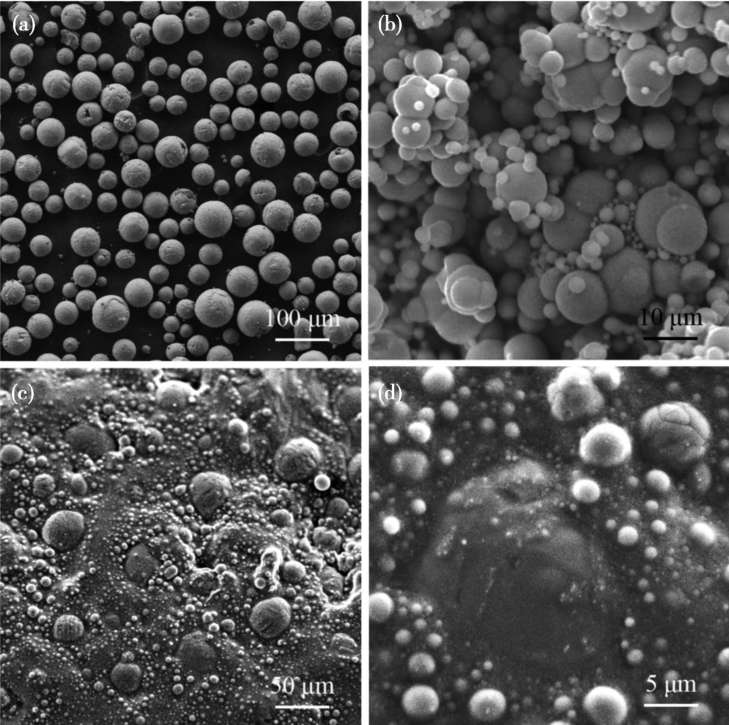

Zou et al. used aluminum oxide powder as a thermal conductive agent, carbonyl iron powder as an electromagnetic wave absorber, and vinyl silicone oil and hydrogen containing silicone oil as adhesives to prepare thermal conductive absorbing silicone rubber. They studied the effect of the ratio of carbonyl iron powder and aluminum oxide powder on the viscosity before vulcanization, thermal conductivity and absorption performance after vulcanization of silicone rubber, providing reference for the design and application of thermal conductive absorbing materials. The thermal conductivity of the prepared thermal absorbing material is 2W/(m · K), the thermal impedance is 6 ℃ · cm2/W, and the reflectivity is less than -5db in the frequency range of 5-15 GHz. The microstructure image of the sample is shown in Figure 1.

Figure 1: Scanning electron microscopy images of (a) alumina, (b) carbonyl iron, (c) W-4, and enlarged image of (d) W-4

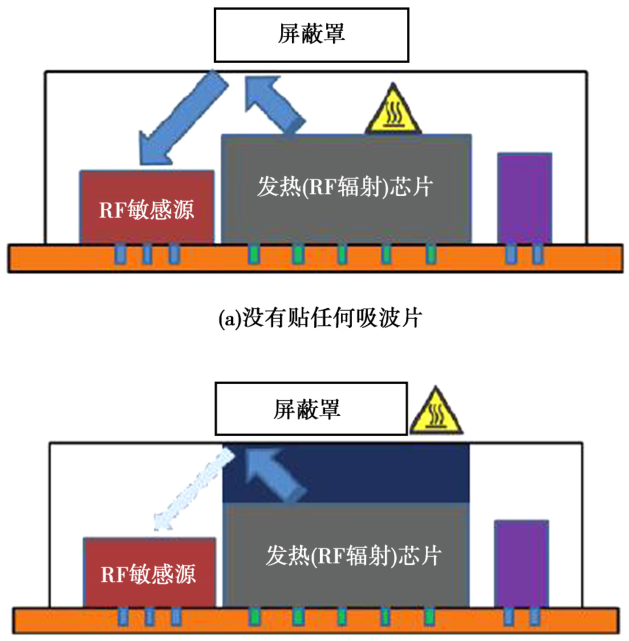

Wang and others have developed a series ofThermal conductive electromagnetic wave absorbing sheetOn the basis of not changing the PCB design of the device, the overheating problem of the device is solved by eliminating interface air and improving heat dissipation efficiency. At the same time, the electromagnetic interference behavior inside or between devices is solved through the absorption function, which has the characteristics of easy operation and significant effect (Figure 2), verifying the practical application value of thermal conductive absorption materials.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2