Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Multi layer ceramic capacitors (MLCC) are the most popular components in current assembly technology, and are one of the important materials in MLCCelectrode slurryBut it has always constrained its development. Traditional slurries are mainly prepared from precious metals, which are expensive and have some shortcomings in application scenarios. Therefore, it is necessary to replace precious metals with base metals to prepare slurries. Among them, the high quality and low price of nickel and copper attract attention. Nickel has been widely studied and applied in practical production. The main direction of copper powder research is to improve its antioxidant properties, making it less susceptible to high-temperature oxidation, thereby reducing production costs.

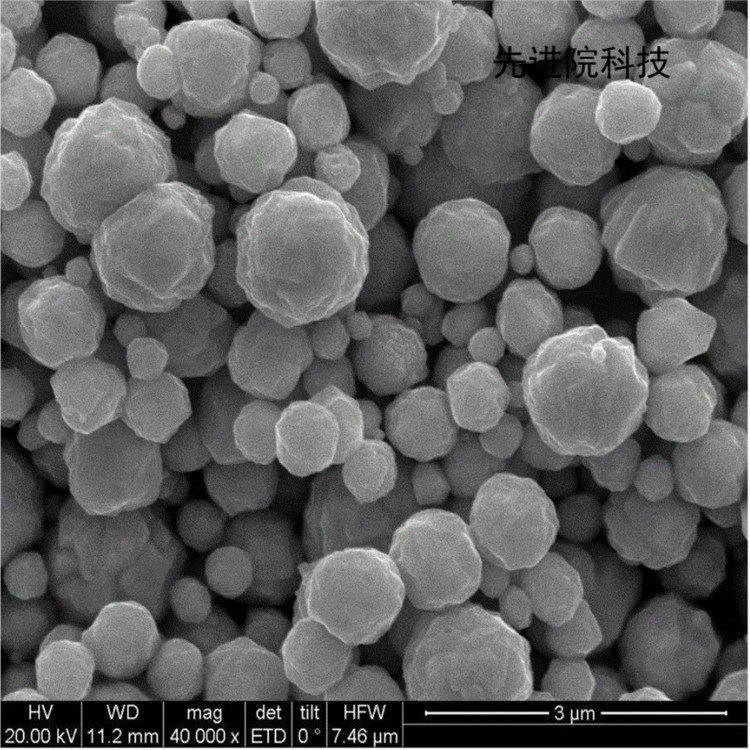

Shenzhen Silver Bag Copper PowderAs a result, it has met the above requirements and become an ideal functional phase material. The development of microelectronics industry has led to an increasing production growth rate of MLCC year by year, and correspondingly, the production of electrode paste has also grown. So, using affordable silver coated copper powder to replace precious metals has excellent market prospects.

At present, the main methods for preparing silver coated copper powder include mechanical mixing, vapor deposition, chemical methods, etc. The mechanical mixing method has a short processing time, tightly coated silver layer, and can achieve large-scale production, but it consumes a large amount of silver. The silver coated copper powder prepared by vapor deposition method has a thin and dense coating layer, good coating effect, and can achieve extremely complete silver plating layer with a small amount of silver. It has good conductivity and oxidation resistance, but the preparation process of this method is complex and the production cost is too high. Chemical reduction coating is considered the most promising method for preparing silver coated copper powder due to its good effect, simple process, energy saving, and environmental protection. Silver coated copper powder, either completely or partially replacing silver powder as a conductive filler, has broad application prospects in the field of low-cost device preparation.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2