Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

The rapid development of modern society has led to the continuous advancement of technology, but the resulting phenomena of electromagnetic radiation and interference are increasing. Electromagnetic interference (EMI) refers to the phenomenon where the normal function of electronic devices is disrupted or obstructed, abbreviated as EMI. In order to reduce the interference of electromagnetic waves, researchelectromagnetic shielding coatingVery important, electromagnetic shielding refers to the use of reflection, attenuation, and other means to prevent electromagnetic radiation from penetrating the shielded area. As a liquid material, conductive coatings have attracted much attention due to their low cost and moderate shielding effect. It can conveniently and quickly form a conductive coating on the surface of various materials through spraying or brushing, in order to shield electromagnetic waves. In recent years, research on silver coated copper powder has not only endowed it with the conductivity of silver powder but also made it less prone to oxidation. Therefore, cost-effective silver coated copper powder has been widely used as a conductive filler in conductive coatings.

Silver coated Copper PowderAs the silver content increases, the thickness of the silver layer thickens, and its color gradually changes from copper red to silver white. Silver coated copper powder with higher coverage has almost the same color as silver powder. Copper and silver have very similar electrical conductivity, but they mainly suffer from the problem of oxidation resistance (copper does not conduct electricity after oxidation and cannot be used as a conductor). Covering the surface of the copper core with a silver package can greatly improve the oxidation resistance of copper and make its conductivity similar to that of pure silver materials, while the price is much lower than that of pure silver products. Silver coated copper powder is an ideal solution to replace pure silver powder and reduce the cost of slurry materials.

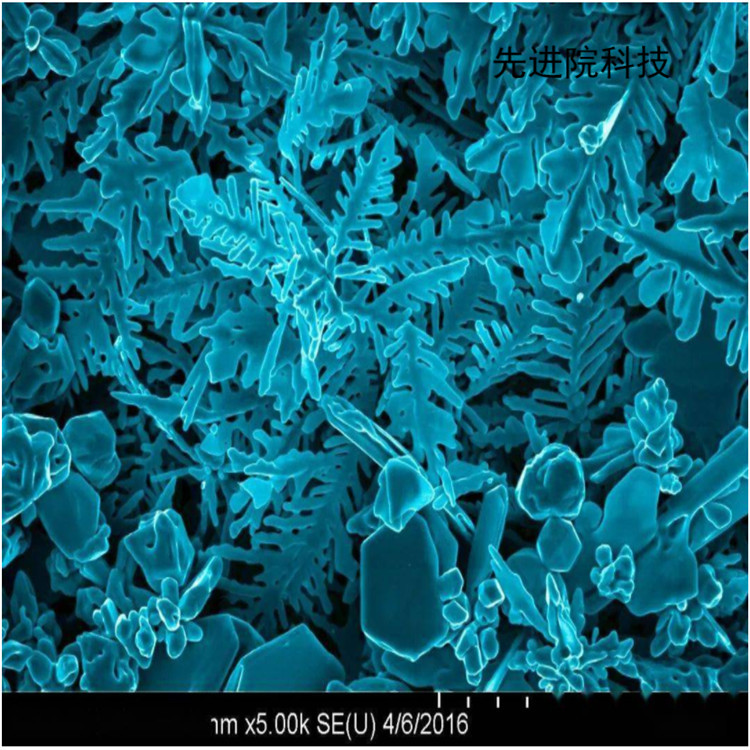

The study on the properties of silver coated copper powder can be summarized as the physical and chemical properties, microscopic and macroscopic characteristics of the powder. The specific characterization methods mainly include: the general properties of the powder (mainly including appearance color, laser particle size, loose packing density, oxygen content, and resistivity), the silver copper content ratio of the powder, the microstructure of the powder, the characteristics of the coating layer of the powder (including element distribution, cross-sectional structure scanning electron microscopy, and coating layer thickness of the powder), and the antioxidant properties of the powder.

1、 Product performance and features:

Silver coated copper powder introduces advanced chemical plating technology from abroad, forming silver coatings of different thicknesses on the surface of ultrafine copper powder. It not only overcomes the defect of copper powder being prone to oxidation, but also solves the problems of expensive silver powder and easy migration. It is a highly conductive material with great development prospects and an ideal cost-effective conductive powder that replaces silver with copper.

2、 Product Application Introduction:

YB-1076 has a high degree of flaking, a smooth and glossy surface, and excellent construction penetrability, such as through ultra-fine needles and precision screen printing. It will not cause blockage and is a good substitute for silver powder for dispensing and screen printing. Extremely strong resistance to high temperatures and sulfurization. Make the product highly weather resistant.

3、 Product Technical Parameters:

| Physical Data |

Inspection |

Unit |

|

| Silver content |

30.03 |

wt% |

|

| Specific surface area (BET) |

1.70 |

m2/g |

|

| tap density |

2.35 |

g/cm3 |

|

| Particle size |

D10 |

3.25 |

μm |

| D50 |

7.32 |

μm |

|

| D90 |

9.75 |

μm |

|

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2