Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

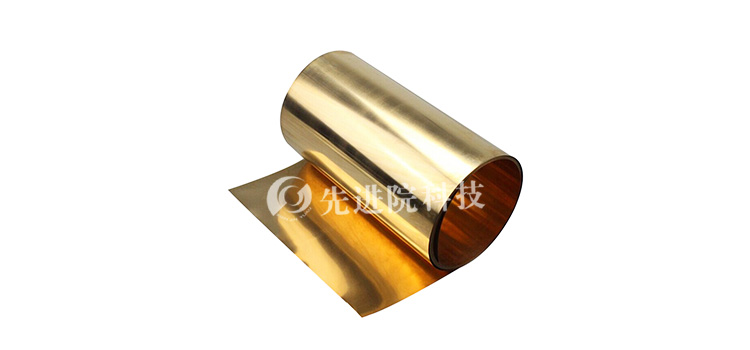

PI PET sputtering gold silver copperUsually refers to magnetron sputtering, which belongs to high-speed and low-temperature sputtering method. This process requires a vacuum degree of around 1 × 10-3Torr, that is, a vacuum state of 1.3 × 10-3Pa, filled with inert gas argon (Ar), and high-voltage direct current applied between the plastic substrate (anode) and the metal target (cathode). Due to the electron excitation of the inert gas by glow discharge, plasma is generated, which ejects the atoms of the metal target and deposits them on the plastic substrate.

Charged particles with kinetic energy of tens of electron volts or higher are used to bombard the surface of materials, causing them to splash out into the gas phase, which can be used for etching and coating. The number of atoms sputtered by an incident ion is called the sputtering yield. The higher the yield, the faster the sputtering speed, with Cu, Au, Ag being the highest and Ti, Mo, Ta, W being the lowest. Usually between 0.1-10 atoms/ion. Ions can be generated by direct current glow discharge, where high voltage is applied between the two poles to generate discharge. Positive ions will bombard the negatively charged target material and sputter it onto the target material, depositing it onto the object to be plated.

The sputtering machine consists of a vacuum chamber, exhaust system, sputtering source, and control system. Sputtering sources are divided into power sources and sputtering gunsMagnetron sputteringGuns are divided into flat and cylindrical types, with the flat type being rectangular and circular. The target material utilization rate is 30-40%, while the cylindrical type has a target material utilization rate>50%. Sputtering power sources include direct current (DC), radio frequency (RF), and pulse, DC: Used for 800-1000V (Max) conductors, must be arc resistant.

UV anti adhesive pressure-sensitive adhesive (PSA) adhesive

Semiconductors are key components of household digital products and electronic devices. In the manufacturing process of large-scale integrated circuits and semiconductor devices, the essential basic material is semiconductor chips. Semiconductor chips are processed from single crystal silicon wafers, abbreviated as wafers. When cutting and grinding wafer materials, a special protective film is required for bonding and fixing. After processing, completely peel off the processed wafer slices from the fixed adhesive film without affecting the wafer material itself. Crystal (decorative glass) is used in daily life such as lighting fixtures and clothing, while optical glass used in optical instruments also requires cutting and grinding. During the processing, a protective film is also needed to fix it, and it can be easily peeled off after processing.

1. Main applications:

Packaging field: cutting of various packaging components (QFN/BGA/DFN); Used for wafer grinding and cutting.

In the field of optics, it is used for slotting, cutting, and pickling of various coated glass and ordinary glass.

Other fields: High adhesive tape is required for processing, and after processing, the tape needs to be peeled off without any residue.

2. Product advantages;

1. It has high adhesion before UV irradiation, which can ensure the stability of the workpiece during the processing;

After UV irradiation, the adhesion almost disappears, and the workpiece is easy to peel off without residual glue or impurities transferring to the surface of the workpiece;

3. It has good ductility, making it easy to expand the membrane and take particles;

4. It has certain temperature resistance and can meet the use of special temperature processes.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2