Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

The range of new energy vehicles has always been an important concern for consumers. In addition to being related to the battery charge of new energy vehicles, the range can also effectively solve the problem of charging speed. In general, slow charging is mainly based on alternating current, while fast charging is mostly based on direct current. The power battery itself only accepts DC charging, and the car is equipped with an on-board charger, which is a device that converts AC to DC.

The higher the power of the car charger, the greater the charging power it can carry and the faster the charging. The upgraded design of the car charger integrates multiple functions, including bidirectional power conversion and DC to DC conversion, making the overall design of the car charger more compact. The compact design also brings certain problems. Integrated and multifunctional chargers generate additional power loads due to DC-DC conversion, and the thermal management issues of on-board chargers become increasingly severe.

All electronic components of the car charger need to be enclosed in a sealed housing environment to prevent environmental pollution. This requires these electronic devices with huge heat generation, such as chips, MOSFETs, etc., to be in contact with the inner wall of the metal mold housing to effectively achieve heat transfer. Therefore, the car charger is in useThermal conductive materialWhen doing so, it is not only necessary to consider good thermal conductivity, but also to have the ability to fill the small gaps between components to a large extent, reduce overall thermal resistance, and achieve good thermal conductivity. The two-component thermal conductive gel produced by the Advanced Institute of Technology has such good heat dissipation performance, and its excellent high and low temperature mechanical properties and chemical stability also meet the relevant requirements of the vehicle charger.

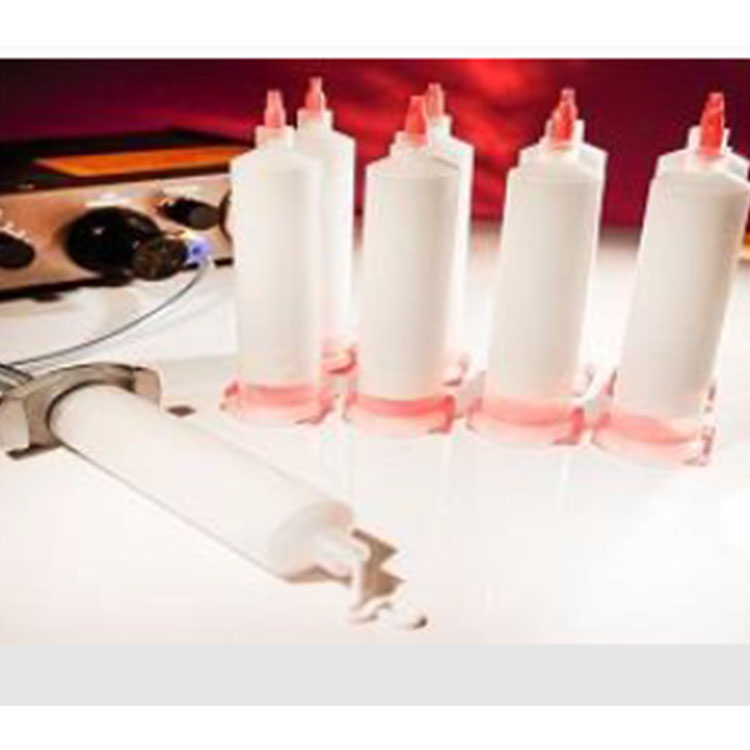

Two component thermal conductive gelIt is a high thermal conductivity, liquid gap filling material with two-component and different temperature curing time characteristics. Their flexibility and elasticity make them suitable for covering very uneven surfaces. Heat is conducted from the separation device or the entire PCB to the metal casing or diffusion board, thereby improving the efficiency and service life of the heat generating electronic components. In liquid form, various thicknesses are provided to replace the die-cutting thickness of general thermal pads, and unlike general silicone sheets, this series of products is dry and touchable after curing, making it more widely applicable.

"Two component thermal conductive gel"

Characteristics of two-component thermal conductive gel:

1. Good thermal conductivity of 4.5W/mk-10W/mk

2. Two component material, easy to store.

3. Excellent high and low temperature mechanical properties and chemical stability.

4. The curing time can be adjusted according to the temperature.

5. The thickness can be adjusted using automated equipment.

6. Can be easily used for automated operation of dispensing systems.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2