Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

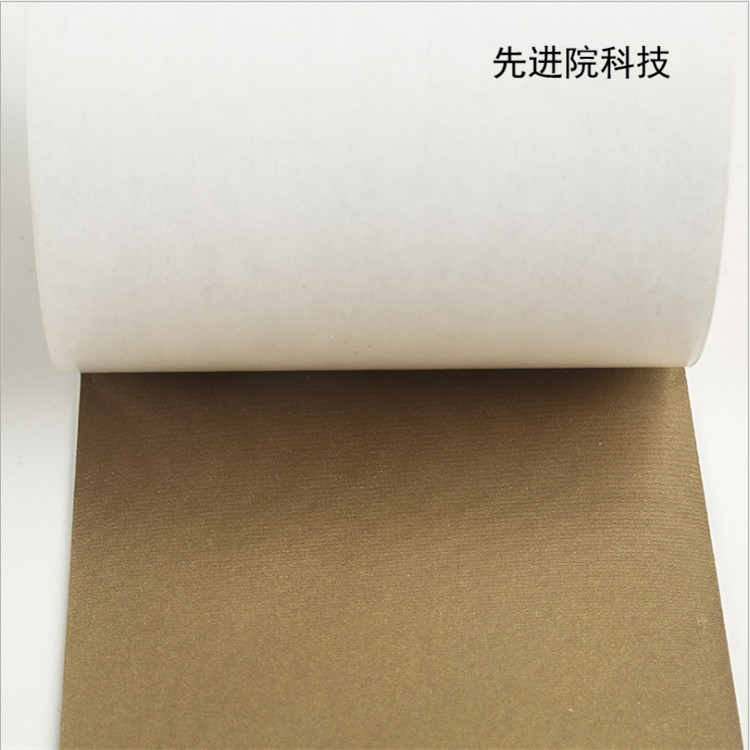

Vacuum gold platingIt is the process of vaporizing low boiling point metals such as A1, Gr, Cu, etc. in a vacuum container and condensing them on the surface of plastic to form a uniform metal conductive film. Vacuum gold plating can be applied to various plastics, with good conductivity and fast deposition speed of the coating. However, the size of the vacuum container limits the size of plastic products, and it has a good effect on flat surface treatment. For complex shaped surfaces, it is difficult to control the uniformity of the film thickness. In order to improve the adhesion between the coating and the plastic, it is necessary to keep the plastic surface highly clean and free from contamination. Usually, the plastic surface is pre treated to remove impurities and make the treated surface rough, in order to improve the adhesion of the metal coating. Pre processing

There are generally three methods of treatment: spraying iron sand for cleaning, chemical etching, and applying primer. The primer coating method is a good pre-treatment method, which does not require special sandblasting equipment, has a fast production speed, and does not cause significant chemical pollution. For polyolefin plastics, corona treatment is required before spraying to increase the content and polarity of surface oxidation groups.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2