Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

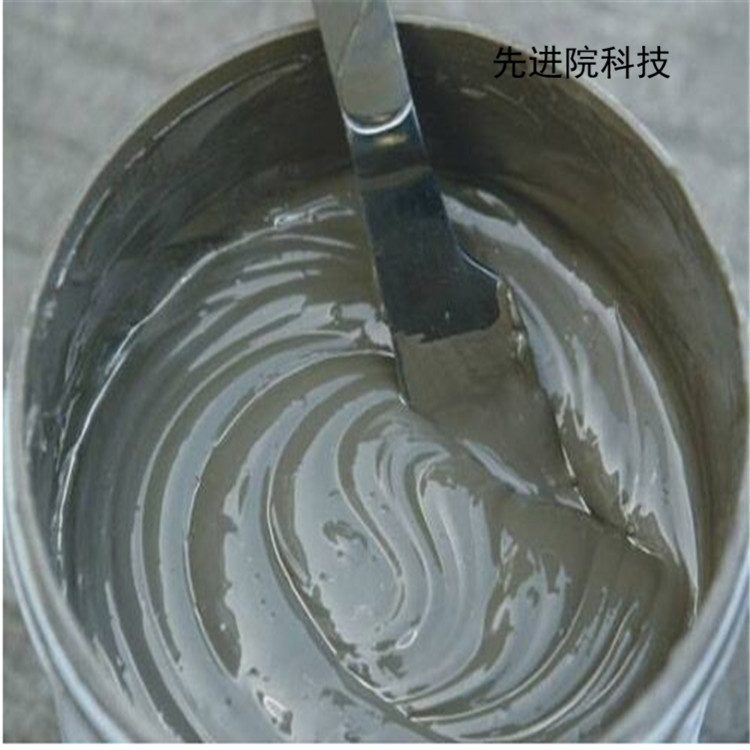

epoxy resinIt is a type of polymer with the molecular formula (C11H12O3) n, which refers to a general term for a class of polymers containing two or more epoxy groups in their molecules. It is the condensation product of epichlorohydrin with bisphenol A or polyols. Due to the chemical activity of epoxy groups, various compounds containing active hydrogen can be used to open the ring, cure and crosslink to form a network structure, making it a thermosetting resin. Bisphenol A-type epoxy resin not only has the largest production and the most complete variety, but also new modified varieties are constantly increasing, and the quality is constantly improving. Epoxy resin refers to a general term for polymer compounds with two or more epoxy groups in the polymer chain structure, belonging to thermosetting resins. The representative resin is bisphenol A-type epoxy resin.

2、 Characteristics of epoxy resin (usually referring to bisphenol A epoxy resin)

1. The application value of epoxy resin alone is very low, and it needs to be used in conjunction with curing agents to have practical value.

2. High adhesive strength: in synthetic adhesivesEpoxy Resin AdhesiveThe adhesive strength ranks among the top.

3. The curing shrinkage rate is small, and the shrinkage rate of epoxy resin adhesive is the smallest in adhesives, which is also one of the reasons for the high curing bonding of epoxy resin adhesive.

For example, phenolic resin adhesive: 8-10%; Organic silicone resin adhesive: 6-8%

Polyester resin adhesive: 4-8%; Epoxy resin adhesive: 1-3%

If the shrinkage rate of epoxy resin adhesive after modification processing can be reduced to 0.1-0.3%, and the thermal expansion coefficient is 6.0 × 10-5/℃

4. Good chemical resistance: Ether groups, benzene rings, and fatty hydroxyl groups in the curing system are not easily corroded by acids and bases. It can be used for two years in seawater, petroleum, kerosene, 10% H2SO4, 10% HCl, 10% HAc, 10% NH3, 10% H3PO4, and 30% Na2CO3; And soak in 50% H2SO4 and 10% HNO3 at room temperature for six months; Soak in 10% NaOH (100 ℃) for one month, and the performance remains unchanged.

5. Excellent electrical insulation: The breakdown voltage of epoxy resin can be greater than 35kV/mm. 6. Good process performance, stable product size, good resistance, and low water absorption rate. The advantages of bisphenol A epoxy resin are undoubtedly good, but there are also its disadvantages: ①. The operating viscosity is high, which is somewhat inconvenient in construction ②. The cured material is brittle and the elongation is small ③ Low peel strength. ④ Poor resistance to mechanical and thermal impacts.

3、 Characteristics of epoxy resin

1. Epoxy resin adhesive is a process of reprocessing or modifying the properties of epoxy resin to meet specific requirements. Usually, epoxy resin adhesive also requires a curing agent to be used, and it needs to be mixed evenly before it can be completely cured. Generally, epoxy resin adhesive is called A adhesive or main agent, and the curing agent is called B adhesive or curing agent (hardener).

2. The main characteristics reflecting the epoxy resin adhesive before curing include: color, viscosity, specific gravity, ratio, gel time, usable time, curing time, thixotropy (flow stop), hardness, surface tension, etc. Viscosity: refers to the internal frictional resistance generated by colloids in flow, and its value is determined by factors such as substance type, temperature, and concentration.

Gel time: the curing of glue is a process from liquid to curing. The critical state time from the beginning of the reaction of glue to the time when the colloid tends to solid is the gel time, which is determined by the mixing amount of epoxy resin glue, temperature and other factors.

Thixotropy: This characteristic refers to the phenomenon where the colloid changes from thick to thin with external forces (shaking, stirring, vibration, ultrasonic waves, etc.), and when external factors stop acting, the colloid returns to its original consistency.

Hardness: refers to the material's ability to resist external forces such as stamping and scratching. According to different testing methods, there are Shore hardness, Brinell hardness, Rockwell hardness, Mohs hardness, Barcol hardness, Vickers hardness, etc. The value of hardness is related to the type of hardness tester. Among the commonly used hardness testers, the Shore hardness tester has a simple structure and is suitable for production inspection. The Shore hardness tester can be divided into A type, C type, and D type. A type is used to measure soft colloids, while C and D types are used to measure semi hard and hard colloids.

Surface tension: The attractive force of molecules inside a liquid causes molecules on the surface to exert an inward force, which minimizes the surface area of the liquid and forms a force parallel to the surface, known as surface tension. Or rather, it is the mutual pulling force between adjacent parts of a liquid surface per unit length, which is a manifestation of molecular force. The unit of surface tension is N/m. The magnitude of surface tension is related to the properties, purity, and temperature of the liquid.

3. The main characteristics reflecting the cured properties of epoxy resin adhesive include resistance, voltage resistance, water absorption, compressive strength, tensile strength, shear strength, peel strength, impact strength, heat deformation temperature, glass transition temperature, internal stress, chemical resistance, elongation rate, shrinkage coefficient, thermal conductivity, electrical conductivity, weather resistance, aging resistance, etc.

Resistance: The resistance characteristics of materials are usually described using surface resistance or volume resistance. Surface resistance, in simple terms, refers to the resistance value measured between two electrodes on the same surface, measured in ohms. By combining the electrode shape and resistance value, the surface resistivity per unit area can be calculated. Volume resistance, also known as volume resistivity or volume resistance coefficient, refers to the resistance value measured by the thickness of a material and is an important indicator of the electrical properties of dielectric or insulating materials. The resistance of a 1cm2 dielectric to leakage current, measured in Ω• m or Ω• cm. The higher the resistivity, the better the insulation performance.

Proof voltage: also known as dielectric strength, the higher the voltage applied to both ends of the colloid, the greater the electric field force on the charges inside the material, making it more prone to ionization collisions and causing colloid breakdown. The lowest voltage required to break down an insulator is called the breakdown voltage of the object. When a 1mm thick insulation material is broken down, the required voltage in kilovolts is called the insulation withstand strength of the insulation material, also known as the withstand voltage. The unit is: Kv/mm。 The insulation performance of insulation materials is closely related to temperature. The higher the temperature, the worse the insulation performance of the insulation material. To ensure insulation strength, each insulation material has an appropriate maximum allowable working temperature. Below this temperature, it can be used safely for a long time, but beyond this temperature, it will rapidly age.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2