Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

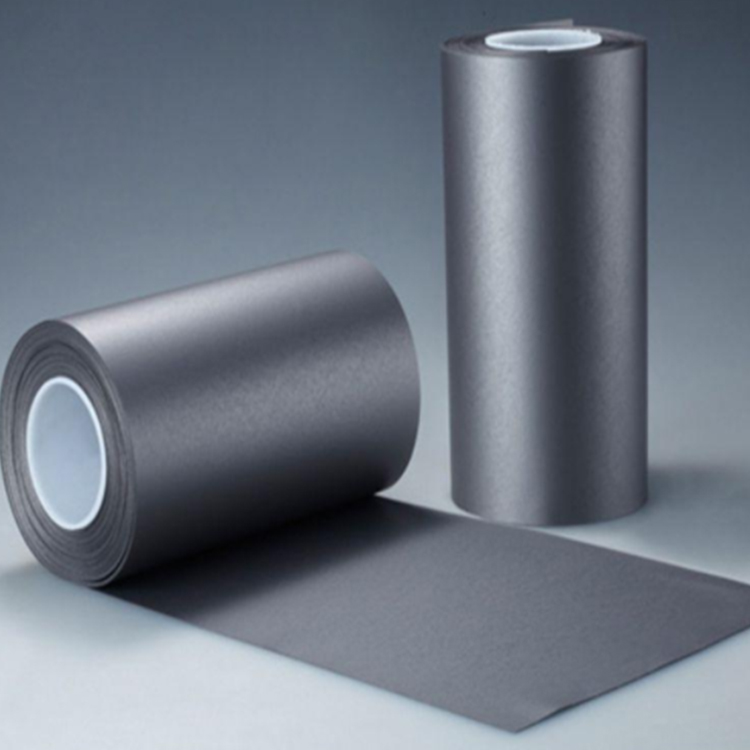

With the development of electromagnetic information and other technologies, at room temperatureElectromagnetic wave shieldingCannot meet the demand anymore. Although carbonyl iron powder has good temperature stability, its oxidation temperature is about 200 ℃, and its oxidation resistance is poor. Therefore, it is particularly important to carry out antioxidant treatment on carbonyl iron powder. Experiments have shown that reacting carbonyl iron powder with other substances to form a core-shell structure and coating it with a nanoshell layer helps to improve the thermal stability of carbonyl iron. The density and content of the shell layer are the main factors affecting the heat resistance of core-shell composite particles, and the Fe/SiO2 that forms the core-shell structure can also suppress eddy current losses. In addition, the use of conductive polymers can also improve the oxidation resistance of carbonyl iron powder. It can be improved by coating a layer of polyaniline resin on carbonyl iron powderCarbonyl iron powderAntioxidant and anti-corrosion properties. After coating with a layer of polyaniline, a γ - Fe2O3 oxide layer is formed at the interface between polyaniline and carbonyl iron powder to prevent further oxidation of carbonyl iron powder and increase the dielectric constant.

Good absorbing materials should meet the following conditions:

(1) When electromagnetic waves propagate to the surface of materials, they can maximize the entry of electromagnetic waves into the interior of the material and reduce direct reflection of electromagnetic waves;

(2) Electromagnetic waves can rapidly attenuate when propagating inside materials.

In order to achieve non reflection, it is required that the dielectric constant is equal to the magnetic permeability. A good absorbing coating requires a good match between the dielectric constant and magnetic permeability. However, using only dielectric loss absorbers or magnetic loss absorbers as absorbers will result in a mismatch between the complex dielectric constant and the complex magnetic permeability. Carbonyl iron powder can achieve good absorption effect when used in combination with magnetic loss absorbent and dielectric loss absorbent. This provides theoretical and experimental support for the widespread application of carbonyl iron powder. In order to improve the absorption characteristics and oxidation resistance of absorbing coatings using carbonyl iron powder as the absorbent, other types of absorbents are often used together with carbonyl iron powder as the absorbent and modified.

Choosing the appropriate substrate and modifying it appropriately is also one of the key factors in the design and preparation of absorbing coatings. The absorbing coating applied to the outer surface of aircraft must have good high temperature resistance while meeting various mechanical properties. Epoxy resin has received increasing attention due to its excellent high temperature resistance.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2