Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

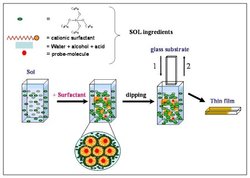

The preparation of inorganic organic composite nanomaterials through the sol gel process technology is the most common and mature method to prepare inorganic organic composite materials at present. The synthesis of traditional inorganic glass and ceramic materials is carried out under high temperature (>1200 ℃) and high pressure conditions, under which polymer materials undergo thermal decomposition, which determines that high temperature cannot be used in the preparation of hybrid materials.Sol-gelIt is a low-temperature soft chemistry method for preparing materials, which avoids the limitations of operating at high temperatures and provides an important pathway for synthesizing hybrid materials. Sol gel process refers to the process of dissolving alkoxy metals or metal alkoxides and other precursors into sol under certain conditions, and then using solvent volatilization or heating treatment to convert the solution or sol into inorganic oxide gel with spatial network structure, including system mixing, gel aging and drying. Sol gel method can be divided into in-situ sol gelation, sol in-situ polymerization and inorganic according to the sequence of mixed sol and gel of inorganic organic components-Organic synchronous polymerization method, etc.

You can use the already madeNano scale inorganic powderAs a filler and polymer matrix for blending and dispersing composites, it is required that the dispersed phase can be prepared into nanoscale powders. The common methods for preparing inorganic nano powders include high-energy ball milling, ultrasonic grinding, microemulsion, hydrothermal, pyrolysis, chemical reaction precipitation, laser CVD, etc. Dispersed blend composites have the advantage of being direct and convenient. Inorganic powders can also be mixed with polymer particles in a certain proportion and then subjected to high-energy ball milling to further obtain nanoscale composite materials. Powder coating means that nano inorganic powder is coated on the surface of large particle polymer powder, and a polymer coating layer can also be formed on the surface of inorganic nano powder. The encapsulation of the two through intermolecular forces and hydrogen bonding is called adsorption encapsulation. The coating formed by the interaction of chemical bonds is called graft coating. Powder coating is beneficial for enhancing the dispersibility, stability, and compatibility with polymers of inorganic phases. The above composite can be directly processed and formed, or added as a filler to other polymers or paints as a stealth coating material. On single crystal silicon wafers, quartz wafers, gold surfaces, and graphitesilica nanoparticlesThere are also many studies on the synthesis of organic/inorganic composite materials using ATRP on substrates such as MnFe2O4 nanoparticles with ferromagnetism, organic fibers, silica gel surfaces, and high crosslinking polystyrene latex balls.

In addition, monomers suitable for the application of ATRP method may contain silicon elements that can be hydrolyzed, making the hydrolysis of ATRP to obtain organic/inorganic hybrid materials a simple method for obtaining organic/inorganic composite materials. Wang et al. introduced peroxide group initiators on the surface of inorganic materials and performed reverse ATRP on their surfaces. Then, using the active initiator fragments at the end of their polymer chains, they performed forward ATRP on other monomers to prepare block copolymer grafted organic/inorganic composite materials.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2