Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

It is said that there were originally no metals on Earth, but planets that repeatedly collided with Earth brought various metals to the planet. Obviously, the randomness of planetary impacts is too strong and has caused certain difficulties for the inhabitants of Earth, one of which is lithium. This is currently the most widely used metal in electrochemical energy storage systems, but China, the most prosperous region in the lithium battery industry, is struggling with insufficient lithium resources. However, other metals have also entered the field of batteries, making electrochemical energy storage diverse.

Are lithium iron phosphate and ternary really competitors?

Speaking of which, lithium iron phosphate batteries and ternary batteries are brothers in the field of lithium-ion batteries. However, in the past two years, there seems to be a trend of fierce competition between them. Especially on November 18th, after the Ministry of Industry and Information Technology released the draft of the "Standard Conditions for the Lithium ion Battery Industry (2021 Edition)" and the "Management Measures for the Announcement of Lithium ion Battery Industry Standards (2021 Edition)" (Draft for Comments), the industry found that there seems to be a certain tendency to inhibit the rapid progress of lithium iron phosphate batteries

The new standard requires that the energy density of individual cells in energy type power battery projects should be ≥ 180Wh/kg, and the energy density of battery packs should be ≥ 120Wh/kg. Although the energy density of lithium iron phosphate battery packs exceeds 120, the individual cell number is somewhat dangerous because the mainstream lithium iron phosphate battery cell energy density is still hovering around 160Wh/kg. According to this calculation, many products cannot meet the new regulations.

But are the new regulations really suppressing lithium iron phosphate batteries?

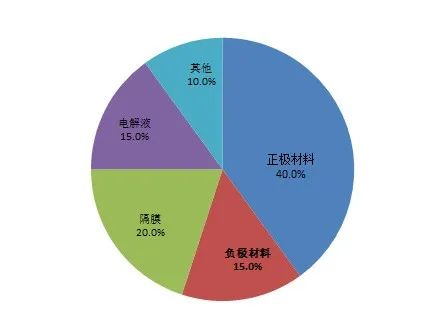

Let's start with the positive electrode material. Just as the rich flavor of the pot bottom is the soul of hotpot, the positive electrode material also plays the role of the soul of lithium batteries. In the manufacturing cost of batteries, positive electrode materials account for about 40%.

Because of its importance, even lithium-ion batteries are distinguished by positive electrode materials. After more than 30 years of development, the main positive electrode materials used in lithium batteries have entered industrialization, including lithium cobalt oxide (LCO), lithium manganese oxide (LMO), lithium iron phosphate (LFP), and ternary materials (NCM, NCA). Lithium iron phosphate and ternary batteries are the two largest types of power batteries, so they are particularly eye-catching. In addition, Dong Mingzhu's Yinlong Company uses a material called lithium titanate (LTO), but lithium titanate is not used as a positive electrode material, but as a negative electrode material. The positive electrode material of lithium titanate batteries is still lithium iron phosphate or ternary materials.

The name "ternary" comes from three metals, referring to the use of nickel cobalt manganese (NCM) or nickel cobalt aluminum (NCA) as positive electrode materials. Using nickel salt, cobalt salt, and manganese salt (aluminum) as raw materials, the proportions of the three can be adjusted according to actual needs.

In the field of power batteries, lithium iron phosphate batteries and ternary batteries compete because each has its own advantages.

From the table, it can be seen that compared with ternary materials, lithium iron phosphate has the advantages of high safety, low cost, and lower energy density.

Due to its cost advantage, before 2017, lithium iron phosphate batteries in power batteries were considered unbeatable due to their relatively low cost. But in 2017, due to policy subsidies encouraging high energy density, ternary batteries quickly caught up and replaced lithium iron phosphate batteries as the mainstream, reaching a peak of 68% of power batteries.

However, with the decline or even disappearance of policy subsidies, coupled with the gradual increase in safety requirements, lithium iron phosphate has once again risen. Since the beginning of last year, the installed proportion of lithium iron phosphate batteries has been catching up with ternary batteries from 38.3%. By June this year, the installed capacity of lithium iron phosphate batteries had exceeded that of ternary batteries, and by November this year, it had exceeded the installed capacity of ternary batteries for five consecutive months.

So is the new regulation on November 18th this year, which reintroduces energy density, really repeating the old path of 2017?

The answer is: not so. In fact, the new regulations also require ternary batteries to have a specific capacity of ≥ 175Ah/kg for ternary materials. In the "2021 Edition of Lithium ion Battery Industry Standard Conditions" determined on December 10th, the specific capacity of ternary materials is reduced to ≥ 165Ah/kg. At present, there is no doubt that high nickel materials of ternary 8 series and above meet the standards, but some enterprises with mass production specific capacity of ternary 5 series and below may not meet the standards. Obviously, ternary batteries are not worry free.

That is to say, the country has put forward higher requirements for both lithium iron phosphate and ternary materials, and both need to demonstrate their advantages in longer tracks.

At present, lithium iron phosphate materials have been popular in the phosphate chemical market for many years, and even several traditional phosphate chemical enterprises such as Xinyangfeng and Yuntianhua have made great strides into the field of lithium iron phosphate. There is still room for them to make great achievements in this track. The achievement of compliant energy density for lithium iron phosphate batteries is the direction of efforts for relevant enterprises.

Similarly, ternary material enterprises also continue to have room for sustained technological efforts. At present, the main direction of ternary material technology is high nickel and low cobalt or even cobalt free. High nickel is used to improve energy density, safety performance, and lifespan, while cobalt free is because cobalt is too expensive. 66% of global cobalt production comes from the unstable political situation in the Democratic Republic of Congo. On December 20th, foreign media reported that the situation in the Democratic Republic of Congo had worsened, compounded by the African pandemic, and cobalt prices were about to rise again. Moreover, cobalt does not participate in electrochemical reactions, so reducing cobalt while increasing nickel content is a good way to improve battery energy density and reduce costs.

Can solid-state lithium batteries and lithium sulfur batteries bear the weight

In order to improve the energy density and safety of lithium batteries, in addition to technological efforts in lithium iron phosphate batteries and ternary batteries, the world is also exploring solid-state lithium batteries (including semi-solid lithium batteries) and lithium sulfur batteries.

In terms of solid-state lithium batteries, Energy Storage Headlines once provided a detailed explanation in the article "With a cycle performance of up to 45000 times! How long is the solid-state battery before it enters the battlefield. It replaces liquid electrolytes with solid substances, increasing the material density of lithium ions or metallic lithium, which can conduct larger currents and thus enhance battery capacity. Because there is no electrolyte in solid-state batteries, they are safer, smaller in size, and have higher energy density.

In addition to safety, the small size is also an attractive advantage of solid-state batteries. In traditional lithium-ion batteries, separators and electrolytes are required, which together account for nearly 40% of the volume and 25% of the mass in the battery. The use of solid electrolytes greatly reduces the thickness of batteries.

All solid state battery technology is also considered by the market as the next generation battery technology.

In addition to lithium titanate batteries, there is also a lithium sulfur battery technology direction, which uses sulfur as the positive electrode material and lithium as the negative electrode. During discharge, the negative electrode reacts as lithium loses electrons and becomes lithium ions, while the positive electrode reacts as sulfur reacts with lithium ions and electrons to form sulfides. The potential difference between the positive and negative electrode reactions is the discharge voltage provided by the lithium sulfur battery. Under the action of applied voltage, the positive and negative electrodes of lithium sulfur batteries undergo reverse reactions, which is the charging process. The theoretical discharge mass specific energy of lithium sulfur batteries is 2600 Wh/kg.

Solid state lithium batteries and lithium sulfur batteries are both promising new technologies that can improve the power density of lithium batteries. The cost of liquid lithium batteries is about 1200-2000 yuan/kWh, but if existing technology is used to manufacture solid-state batteries that can power smartphones, the cost will be as high as 60000 yuan, not to mention the cost of solid-state batteries that can power cars. Therefore, solid-state lithium batteries and lithium sulfur batteries still have a long way to go before they can be commercialized.

Can sodium ion batteries and aluminum ion batteries compete?

On December 20th, CATL responded to investors' questions about sodium ion batteries, stating that the company has already initiated the industrialization layout of sodium ion batteries and will form a basic industrial chain by 2023.

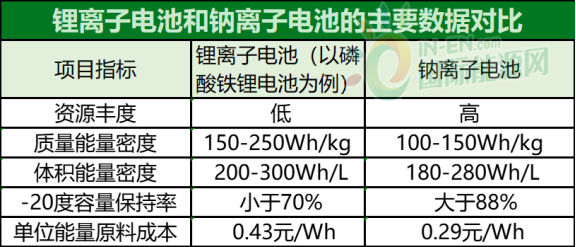

When comparing sodium ion batteries with lithium-ion batteries, one can immediately see their advantages: high sodium abundance, unlike lithium resources that are scarce in many regions of the earth, which also brings about lower costs compared to sodium ion batteries. Another advantage is strong environmental adaptability, with a higher probability of not falling off the chain in low temperature environments compared to new energy vehicles equipped with lithium-ion batteries. But at the same time, it also has a fatal weakness of low energy density.

At a time when the energy density of lithium-ion batteries has to give an awkward smile to the requirements for battery life, the current energy density of sodium ion batteries can only be said to have some reluctance to meet the requirements for battery life. However, CATL has a solution to ensure energy supply by adopting a "hybrid" mode before it can significantly increase the energy density of sodium ion batteries through technology. However, this hybrid is not a gasoline hybrid, but a sodium lithium hybrid.

In July of this year, CATL announced the AB battery solution when the development of sodium ion batteries had already begun. Sodium ion batteries and lithium-ion batteries can be integrated into the same battery system at the same time. By mixing and matching the two types of batteries in a certain proportion and arrangement, they can be integrated in series and parallel. Then, the precise algorithm of BMS can be used to balance and control different battery systems. This can achieve complementary strengths and weaknesses, not only filling the energy density gap of sodium ion batteries at the current stage, but also playing its advantages of high power and low temperature performance. This lithium sodium battery system can be adapted to more application scenarios.

At present, apart from CATL, there are not many companies in China that are focusing on sodium ion batteries, unlike lithium-ion battery companies that are full of talented individuals. Some comments once believed that CATL is the core of the entire power battery industry chain. Ningde Times has chosen the sodium ion battery track, which will also play a crucial leading role in the development of sodium ion batteries.

The current news about aluminum ion batteries mostly comes from Saturnose, an Indian company. However, the development of this technology was also relatively early.

The principle and chemical equation of aluminum ion batteries are relatively simple: high-purity aluminum is used as the negative electrode, oxygen is used as the positive electrode, and potassium hydroxide (KOH) or sodium hydroxide (NaOH) aqueous solution is used as the electrolyte. Aluminum absorbs oxygen from the air and undergoes a chemical reaction during battery discharge, converting aluminum and oxygen into alumina.

Aluminum ion batteries can be fully charged in a short period of time and can be repeatedly charged 7500 times. On the surface, this type of battery is a pollution-free, long-lasting, stable and reliable power source. But since its development began in the 1960s, it has not been widely used because aluminum batteries have a fatal flaw: they are not as corrosion-resistant as lithium batteries. If lithium-ion batteries are not used for a month, they will lose 5% of their power, while aluminum batteries will lose 80% of their power due to aluminum corrosion.

During the discharge process of aluminum batteries, anodic corrosion generates hydrogen, which not only leads to excessive consumption of anode materials, but also increases electrical losses inside the battery. Scientists' response measures include doping high-purity aluminum with specific alloying elements to improve the corrosion resistance of the aluminum anode, or adding corrosion inhibitors to the electrolyte.

Saturnose, which announced in early December this year that it would achieve mass production of aluminum batteries, was found to be a company established in April of this year, and the world is skeptical that it can overcome the "corrosion effect" in just over six months. However, Saturnose claims to have been conducting technical attacks in secret for five years.

If aluminum battery manufacturers can achieve fruitful results in mass production, it will inevitably become a new force in electrochemical energy storage.

As of now, lithium batteries are still far ahead in technology, and lithium iron phosphate and ternary batteries are not inferior. Both need to work hard on the track to meet the requirements of the Ministry of Industry and Information Technology. Sodium batteries and aluminum batteries are also taking exploratory steps, and if they can take a big enough step, it is highly likely to surpass lithium batteries.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2