Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

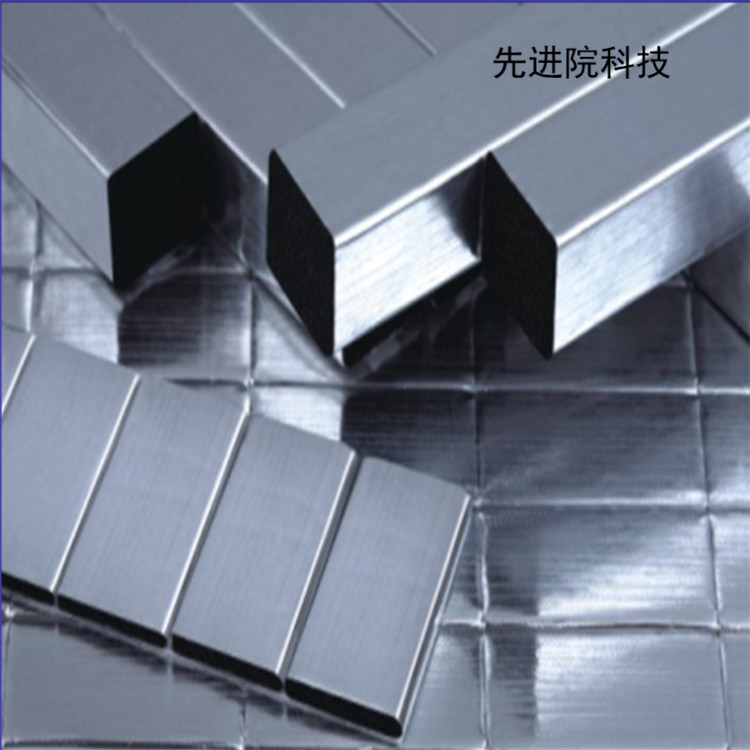

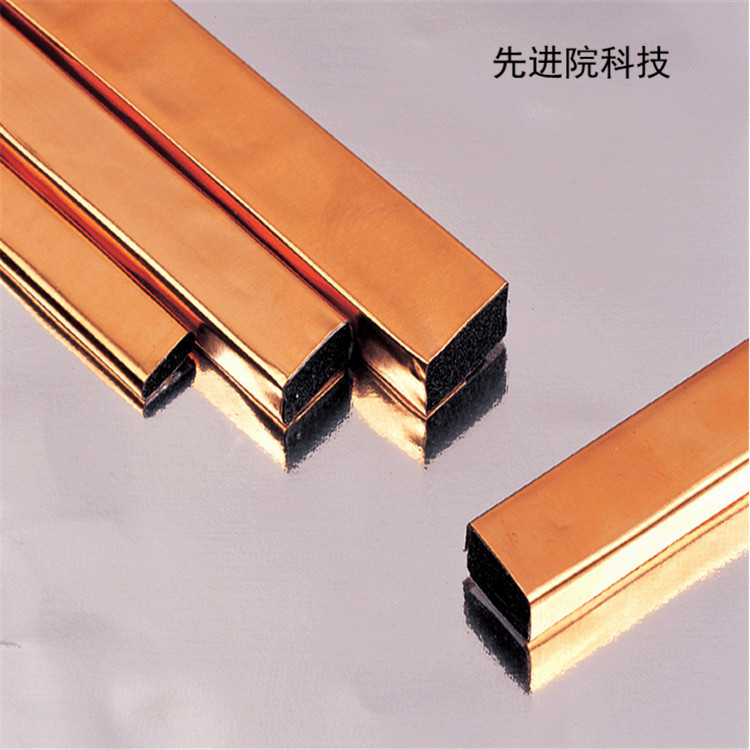

Conductive foamIt can be divided into ordinary conductive foam, gold-plated conductive foam, carbon plated conductive foamTin plated conductive foamConductive aluminum foil copper foil foam, all-round conductive foamSMT conductive foam、 I/O conductive foam pads, etc. Widely used in television, LCD, mobile phones MP4、 In the field of electronic products such as communication cabinets and medical instruments. Today, the conductive foam manufacturer will talk about the hot forming processing technology of conductive foam.

Conductive foam must be dried before hot forming. Hot forming can heat the board, and the heating process can be completed in a baking oven, heating plate, or infrared heater. The heating time range depends on the thickness of the board (approximately 1 millimeter per minute).

Because the quality of conductive foam is relatively small, its specific heat capacity is low. At the same time, the surface of the board is used as a cooling channel due to a large number of cut gaps, and the temperature of the conductive foam surface rapidly decreases, resulting in less heat that can be retained. So the conductive foam board can be insulated to prevent the temperature from rapidly dropping after the conductive foam is taken out of the oven or heating plate, which cannot meet the temperature standards of the thermoforming process.

Conductive foam boardIt can be covered with protective materials such as cotton cloth, breathable felt, etc. The purpose of protecting materials is to ensure that the material sheet can maintain the required temperature for forming for a certain period of time before completion. When the deformation degree of the shape that can be processed is small, the design of the molding mold should strive for simplicity. The heat resistance standard for molds is not very high, and molds made of wood, polyester, epoxy resin, or fiberglass are sufficient. The formation of components can be completed using vacuum/non vacuum rubber molds or female/male molds.

Conductive foam manufacturers remind that in order to ensure that the board can stretch in the mold with low resistance, the edges must have a relatively large curvature. The temperature of conductive foam drops rapidly, and the speed of temperature drop on both sides can be consistent to prevent rebound and deformation. Once the temperature of the formed component drops below 80 ℃, it can be removed from the mold.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2