Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

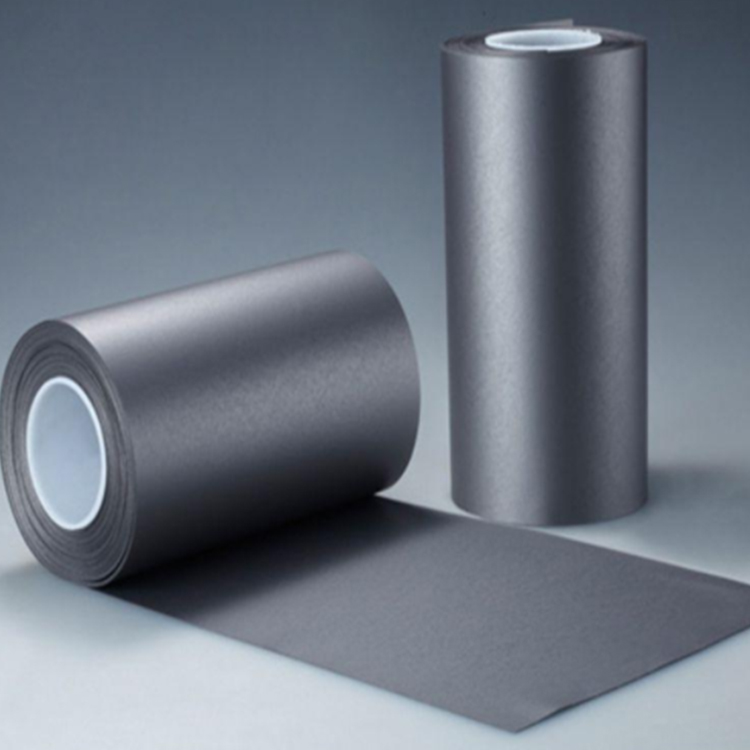

Types of absorbing materials:AbsorberThis product can also be customized with various types of backing adhesive according to customer requirements, and can also be customized with various special-shaped specifications according to customer drawings. (If backing adhesive is needed or not, please contact customer service for instructions. Conventional backing 0.05mm PET double-sided adhesive is available.) Function: Reduce electromagnetic wave interference Magnetic permeability: 20U, 40U, 50U, 80U, 120U, 150U, 180U, 220U, 250U, 300U (± 10%) Thickness: 0.02mm to 1mm (± 10%) Recommended frequency: 1G-6G Width: 300mm Length: 50m/roll (other lengths can be customized) Performance: Light weight, temperature resistance, moisture resistance, corrosion resistance. The reading distance on metal is longer than that without metal, which is The result of the overall design. Principle: Mainly relying on a medium isolated from the metal, while using the metal as a reflective surface, to improve the characteristics of the label on the metal. Physical properties: Anti metal tags are electronic tags packaged with a special anti magnetic absorbing material, which technically solves the problem that electronic tags cannot be attached to metal surfaces for use. The product is waterproof, acid resistant, alkali resistant, and collision resistant, and can be used outdoors. Features: Attaching anti metal electronic tags to metal can achieve good reading performance, even farther than reading in air. Using special absorbing materials, this model of material can effectively prevent metal interference with RF signals. Detailed explanation: In RFID devices, electronic tags

| project |

TECHNICAL INDEX |

testing instrument |

Testing standards |

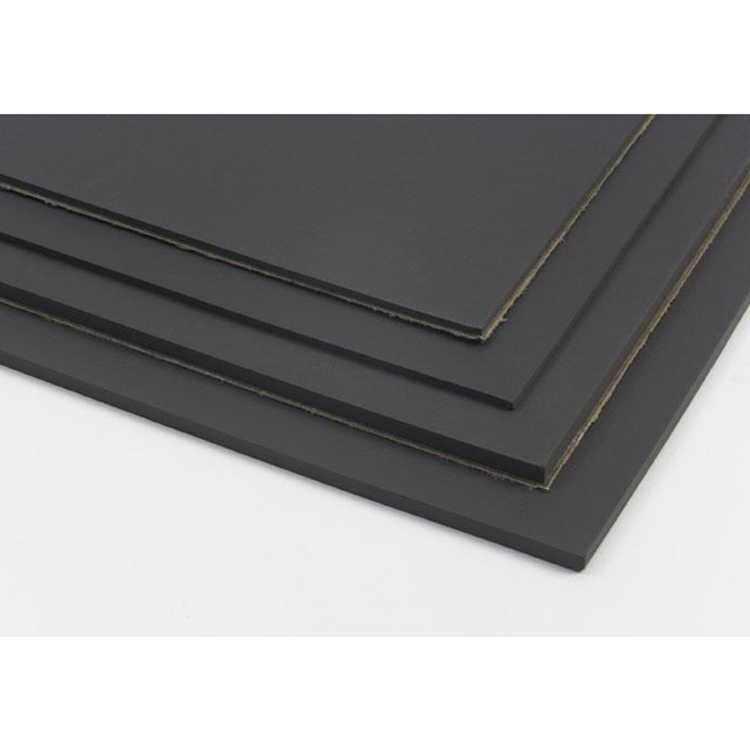

| colour |

Dark Gray |

see |

-- |

| Thickness (mm) |

0.5-3.0 |

PEACOCK thickness gauge |

ASTM D 374 |

| specifications |

120mm×120mm |

Digital calipers |

ASTM D 5947 |

| Density (g/cc) |

3.3(±0.2) |

ZMD-2 electronic density meter |

ASTM D 792 |

| Hardness (Shore 00) |

65(±10) |

LX-C type microporous material hardness tester |

ASTM D 2240 |

| Tensile strength (Mpa) |

≥0.1 |

Tensile testing machine | ASTM D 412 |

| Elongation rate (%) |

≥100 |

Tensile testing machine | ASTM D 412 |

| Tear strength (N/mm) | ≥0.5 |

Tensile testing machine |

ASTM D 624 |

| Compression ratio (%) (@ 50psi) |

≥40(@50psi) |

Compression force tester | ASTM D 695 |

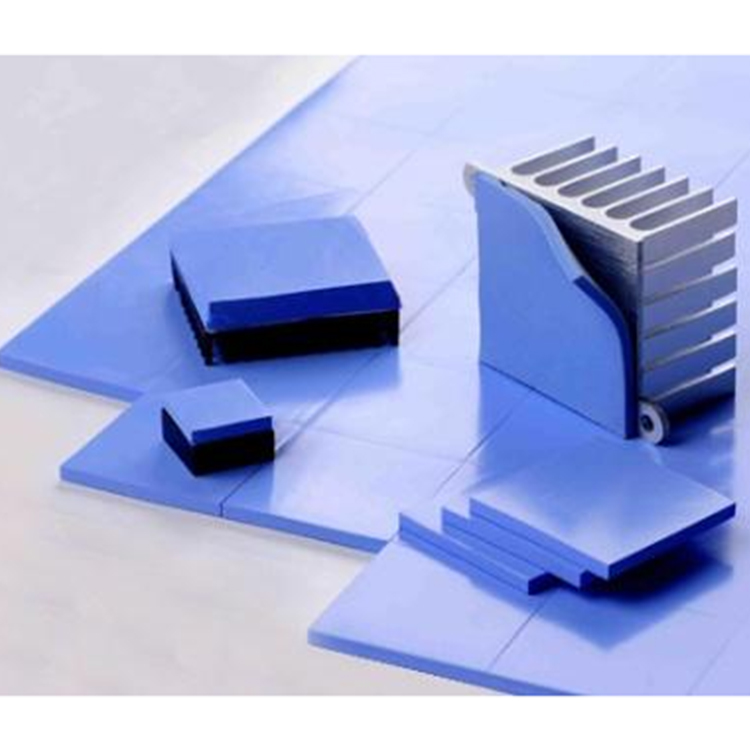

| Thermal conductivity (W/m · K) |

20.0(±5) |

LW-9389 Thermal Conductivity Tester |

ASTM D 5470 |

| Thermal resistance (℃ in2/W) (@ 20psi&1mm) |

≤0.18(@20psi/2mm) |

LW-9389 Thermal Conductivity Tester |

ASTM D 5470 |

| Operating temperature (℃) |

-50~150 |

XB-OTS-150D-C Programmable Thermal Shock Box |

IEC 60068-2-14 |

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2