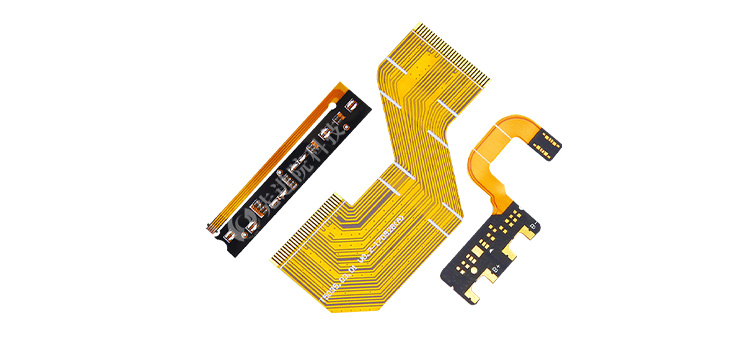

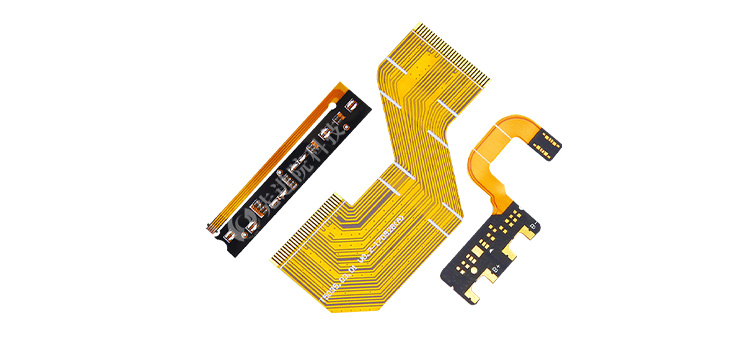

Industrial robot FPC soft board, also known as flexible printed circuit board, is designed specifically for industrial robots, aiming to provide highly flexible and reliable circuit connection solutions.

Product characteristics

- Excellent flexibility:

- FPC flexible board has excellent flexibility and bendability, which can easily adapt to the complex movements of industrial robots, ensuring stable circuit connections at various angles and postures.

- Lightweight design:

- Compared to traditional rigid circuit boards, FPC flexible boards are thinner and lighter, which helps reduce the overall weight of industrial robots, lower energy consumption, and improve the efficiency and flexibility of robot movement.

- High density cabling:

- FPC flexible board supports high-density wiring, which can integrate more circuit components and signal transmission lines in limited space, meeting the needs of industrial robots for highly integrated and miniaturized circuits.

- Good electrical performance:

- FPC flexible board has excellent electrical performance, including low impedance, low loss, high anti-interference ability, etc., ensuring that industrial robots can maintain stable and reliable circuit connections in high-speed and high-frequency working environments.

- High reliability:

- FPC flexible board has good anti vibration and anti impact capabilities, which can maintain stable performance in harsh working environments of industrial robots and extend the service life of robots.

application area

FPC soft boards for industrial robots are widely used in various types of industrial robots, including but not limited to:

- Assembly robot: used to connect robot arms, sensors, actuators and other components to achieve precise assembly tasks.

- Welding robot: provides stable circuit connections during the welding process to ensure welding quality and efficiency.

- Spraying robot: used to connect spraying equipment, sensors and other components to achieve precise spraying control.

- Handling robot: Maintain stable electrical connections when handling heavy objects to ensure the safe operation of the robot.

Technical advantages

- Customized design:

- FPC flexible boards can be customized according to the specific needs and structure of industrial robots, including shape, size, wiring density, etc., to meet the special requirements of different robots.

- Easy to integrate:

- FPC flexible board has the characteristics of being light, thin, and flexible, making it easy to integrate with other components of industrial robots, simplifying the design and production process of robots.

- Easy maintenance:

- The design of FPC flexible board makes circuit connections more flexible and replaceable, making it easier for industrial robots to maintain and repair.

market prospect

With the rapid development of industrial automation and the continuous advancement of industrial robot technology, the market demand for industrial robot FPC soft boards will continue to grow. Especially in the fields of intelligent manufacturing and smart factories, FPC soft boards will play an increasingly important role, providing strong guarantees for the efficient and stable operation of industrial robots.

The FPC flexible board for industrial robots has become an ideal choice for circuit connections due to its unique flexibility, lightweight design, high-density wiring, and high reliability. With the continuous advancement of technology and the expansion of the market, industrial robot FPC soft boards will play a more important role in the future, promoting the sustainable development of the industrial robot industry.