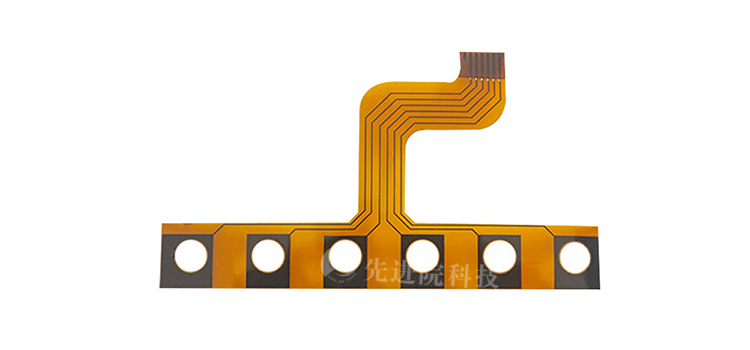

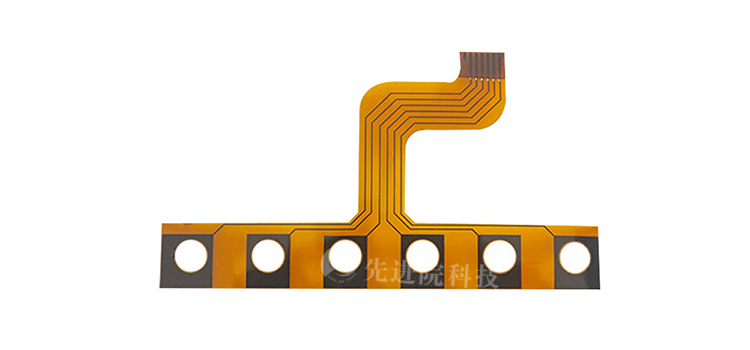

Basic characteristics

- High reliability: FPC flexible board is made of polyimide or polyester film as the substrate, and is manufactured through advanced manufacturing processes, which has high reliability and can ensure long-term stable operation in electronic devices such as digital cameras.

- Excellent flexibility: FPC flexible board can be freely bent, folded, and wound, and can move and stretch freely in three-dimensional space, making it very suitable for electronic devices such as digital cameras that require flexible connections.

- Lightweight and miniaturized: Compared to traditional PCB hard boards, FPC soft boards have lighter weight and smaller volume, which helps reduce the overall weight and volume of digital cameras and improve portability.

Structure and Composition

- Insulation film: As the basic layer of the circuit, the insulation film forms a protective barrier for the circuit, preventing dust and moisture from corroding the circuit. At the same time, it can also reduce stress during bending, ensuring the stability of the circuit.

- Conductor: Copper foil is the main conductor material of FPC flexible board, with good conductivity and flexibility. Copper foil can be made using electroplating or plating processes, and undergo special treatment to improve its adhesion ability.

- Adhesive: Adhesive is used to bond insulation film and conductor together, forming a complete circuit structure. At the same time, it can also serve as a cover layer, providing protective coating and overlay coating to further protect the circuit.

application area

FPC board plays an important role in digital cameras, mainly used in the following areas:

- Signal transmission: As a medium for signal transmission, FPC boards can connect various components in digital cameras to achieve fast and accurate signal transmission.

- Component Connection: Many components in digital cameras need to be connected through FPC boards, such as lens modules, sensor modules, display screen modules, etc. The flexibility and adaptability of FPC boards enable these components to be more tightly integrated together, improving the overall performance of digital cameras.

- Layout optimization: Due to the flexible bending and folding of FPC boards, they can be optimized according to the internal structure and spatial layout of digital cameras, making the circuit more compact and reasonable.

advantages and disadvantages

advantage:

- High degree of freedom: can be arranged arbitrarily according to spatial layout requirements, achieving integration of component assembly and wire connection.

- Small size and light weight: suitable for the development of electronic products towards high density, miniaturization, and high reliability.

- Good heat dissipation: helps improve the stability and lifespan of digital cameras.

Disadvantages:

- High initial cost: The costs of design, manufacturing, and testing are relatively high.

- Difficulty in modification and repair: Once made, it is not easy to modify and repair.

In summary, digital camera FPC board is an electronic component with excellent performance and wide applications. Its high reliability, excellent flexibility, lightweight and miniaturization make it play an important role in electronic devices such as digital cameras.