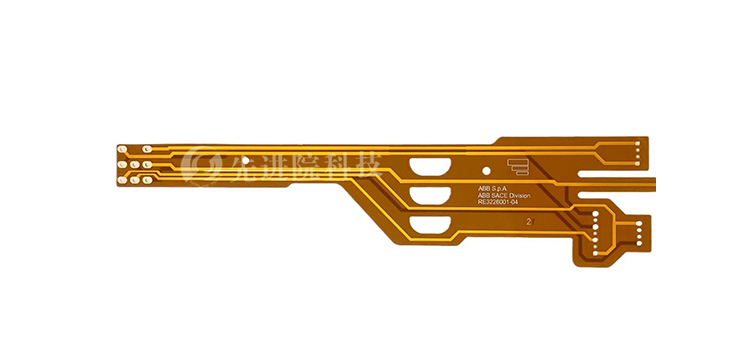

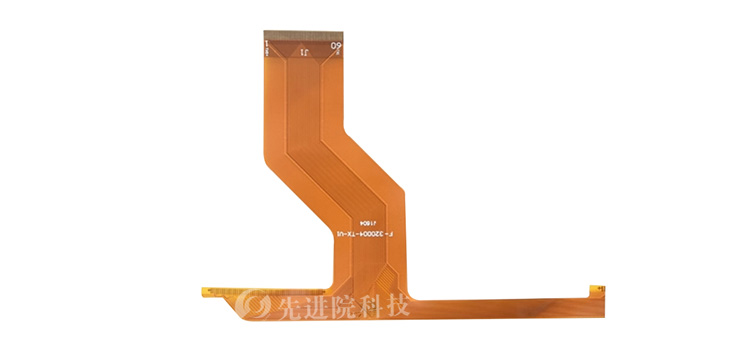

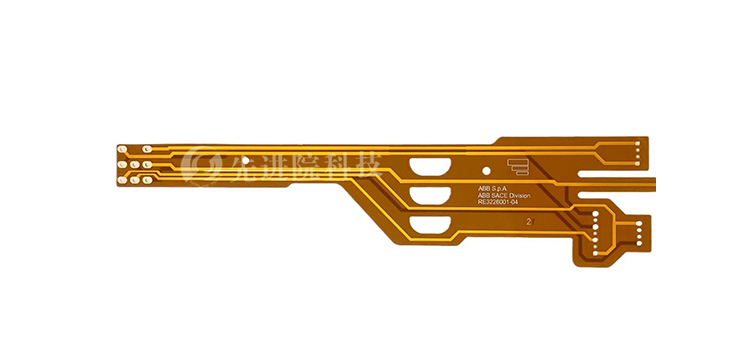

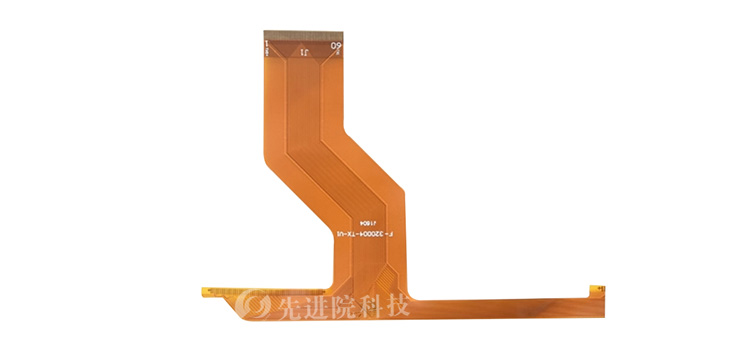

The FPC soft board for aerospace equipment adopts advanced flexible printed circuit board technology, designed specifically for aerospace equipment. It has the characteristics of lightweight, good flexibility, high reliability, high temperature resistance, and high precision, and can work stably in extreme environments, ensuring the normal operation of aerospace equipment and accurate data transmission.

Product Features

- Lightweight and flexible: The FPC soft board for aerospace equipment has a thin thickness, light weight, and good flexibility, which can adapt to the complex spatial layout and vibration environment inside aerospace equipment, making it easy to install and wire.

- High reliability: Made of high-performance materials such as polyimide (PI) substrate, it has excellent temperature resistance, corrosion resistance, and radiation resistance, and can operate stably in extreme environments for a long time, ensuring the reliability of aerospace equipment.

- High temperature resistance: Aerospace equipment may face high temperature environments during operation, and FPC flexible boards need to have good temperature resistance to ensure normal operation under high temperature conditions.

- High precision: Aerospace equipment has extremely high requirements for signal transmission and data processing. FPC soft boards adopt advanced manufacturing processes and technologies to ensure the accuracy and precision of signal transmission, meeting the high-precision needs of aerospace equipment.

- Environmental adaptability: able to adapt to the working requirements of aerospace equipment in different environments, such as extreme environments such as high altitude, low temperature, vacuum, etc.

Product composition

Aerospace equipment FPC soft board usually consists of the following parts:

- Substrate: High performance materials such as polyimide (PI) are used, which have good insulation, high temperature resistance, and radiation resistance.

- Copper foil: forms conductive lines responsible for the transmission of current and signals. The thickness of copper foil and the layout of the circuit are carefully designed to ensure the accuracy and precision of signal transmission.

- Cover film: Covering the surface of copper foil to provide protection and prevent damage to the circuit. The covering film also has certain temperature resistance and radiation resistance, ensuring that the circuit can still be protected in extreme environments.

- Adhesive: Used to laminate substrates, copper foils, and cover films together to form a stable structure. Adhesives need to have good temperature resistance and radiation resistance to ensure the stability of FPC flexible boards in extreme environments.

Product Application

FPC soft boards are widely used in various aerospace equipment, such as satellites, airplanes, rockets, etc. It is responsible for connecting electronic components such as sensors, control systems, and communication systems in aerospace equipment to achieve signal transmission and data processing. For example, in satellites, FPC soft boards are used to connect key components such as solar panels, communication antennas, and control systems; In airplanes, FPC soft boards are used to connect electronic components such as flight control systems, navigation systems, and communication systems.

Product advantages

- Improving equipment performance: The high-precision manufacturing process and technology of FPC soft boards for aerospace equipment ensure the accuracy and precision of signal transmission, thereby enhancing the overall performance of aerospace equipment.

- Enhance equipment reliability: FPC flexible boards made of high-performance materials have good temperature resistance, corrosion resistance, and radiation resistance, ensuring the reliability and stability of aerospace equipment in extreme environments.

- Reducing equipment weight: Aerospace equipment has strict weight requirements, and the lightweight and thin characteristics of FPC soft boards help to reduce equipment weight, improve equipment carrying capacity and flight efficiency.

- Improving equipment integration: FPC flexible board can achieve high-density circuit layout in limited space, improve the integration of aerospace equipment, and make the equipment more compact and efficient.

As an important component of aerospace equipment, FPC soft board plays an important role in the aerospace field due to its lightweight, flexibility, high reliability, high temperature resistance, high precision, and environmental adaptability. With the continuous development of aerospace technology, the application prospects of FPC soft boards in aerospace equipment will be even broader.